Method for extracting saponin active ingredients from bark of acacia mearnsii de willd based on deep eutectic solvents

An active ingredient, a technology of black wattle, which is applied in the field of extracting saponins active ingredients, can solve the problems of difficult manufacturing, many processes, low extraction efficiency, etc., achieves good biocompatibility, wide application prospects, and solves the problem of low extraction rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

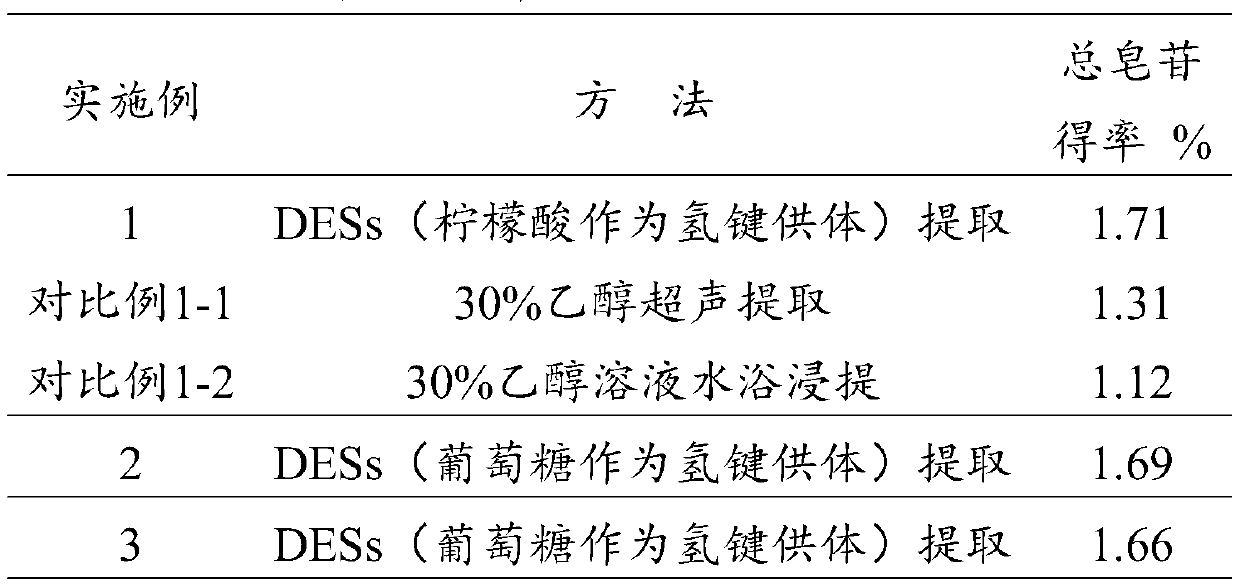

Embodiment 1

[0031] Extraction of Total Saponins from Black Wattle Bark

[0032] The preparation method of the aqueous solution of DESs: heating choline chloride and citric acid under normal pressure at 100° C. for 2-4 hours and synthesizing DESs under continuous stirring until a stable uniform liquid is formed. All prepared DESs were cooled to room temperature and dried in a vacuum oven at 50 °C for 24 h to obtain DESs. Dissolving DESs in water at 30% by volume to obtain a DESs aqueous solution.

[0033]Take 3 parts of 0.5g (accurate to 0.001g) black wattle bark powder (through a 20 mesh sieve) raw material in a 25mL conical flask, add a volume fraction of 30% choline chloride-lemon Acidic DESs aqueous solution, treated at 55°C for 20 minutes, suction filtered, and the filtrate obtained is the active ingredient of saponins.

[0034] The filtrate was transferred to a 100mL volumetric flask, and the 30% ethanol solution was adjusted to 100mL for subsequent determination.

Embodiment 2

[0042] The preparation method of the aqueous solution of DESs: heating choline chloride and glucose under normal pressure at 100° C. for 2 to 4 hours and synthesizing DESs under continuous stirring until a stable uniform liquid is formed. All prepared DESs were cooled to room temperature and dried in a vacuum oven at 50 °C for 24 h to obtain DESs. Dissolving DESs in water at 30% by volume to obtain a DESs aqueous solution.

[0043] Extraction of Total Saponins from Black Wattle Bark

[0044] Take 3 parts of 0.5g (accurate to 0.001g) black wattle bark powder raw material (through 20 mesh sieve) respectively in 25mL Erlenmeyer flask, add volume fraction as 30% choline chloride-glucose DESs with solid-liquid ratio 1g:15mL The aqueous solution was treated at 60°C for 25 minutes, filtered, the filtrate was transferred to a 100mL volumetric flask, and the volume of 30% ethanol solution was adjusted to 100mL for subsequent determination.

Embodiment 3

[0046] The preparation method of the aqueous solution of DESs: heating choline chloride and glucose under normal pressure at 100° C. for 2 to 4 hours and synthesizing DESs under continuous stirring until a stable uniform liquid is formed. All prepared DESs were cooled to room temperature and dried in a vacuum oven at 50 °C for 24 h to obtain DESs. Dissolving DESs in water at 30% by volume to obtain a DESs aqueous solution.

[0047] Extraction of Total Saponins from Black Wattle Bark

[0048] Take 3 parts of 0.5g (accurate to 0.001g) black wattle bark powder raw material (over 20 mesh sieve) respectively in a 25mL conical flask, and add a volume fraction of 30% choline chloride-glucose DESs with a solid-liquid ratio of 1g:10mL The aqueous solution was treated at 55°C for 25 minutes, filtered, the filtrate was transferred to a 100mL volumetric flask, and the volume of 30% ethanol solution was adjusted to 10mL for subsequent determination.

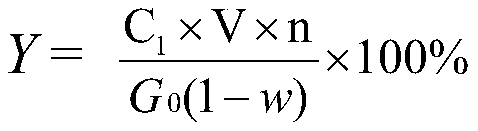

[0049] Taking oleanolic acid as a stand

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap