Gear reduction unit

a gear reduction unit and gear reduction technology, applied in mechanical equipment, transportation and packaging, gearboxes, etc., can solve the problems of reducing efficiency, reducing efficiency, and reducing efficiency, and achieves high contact ratio, double torque capacity, and wide use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

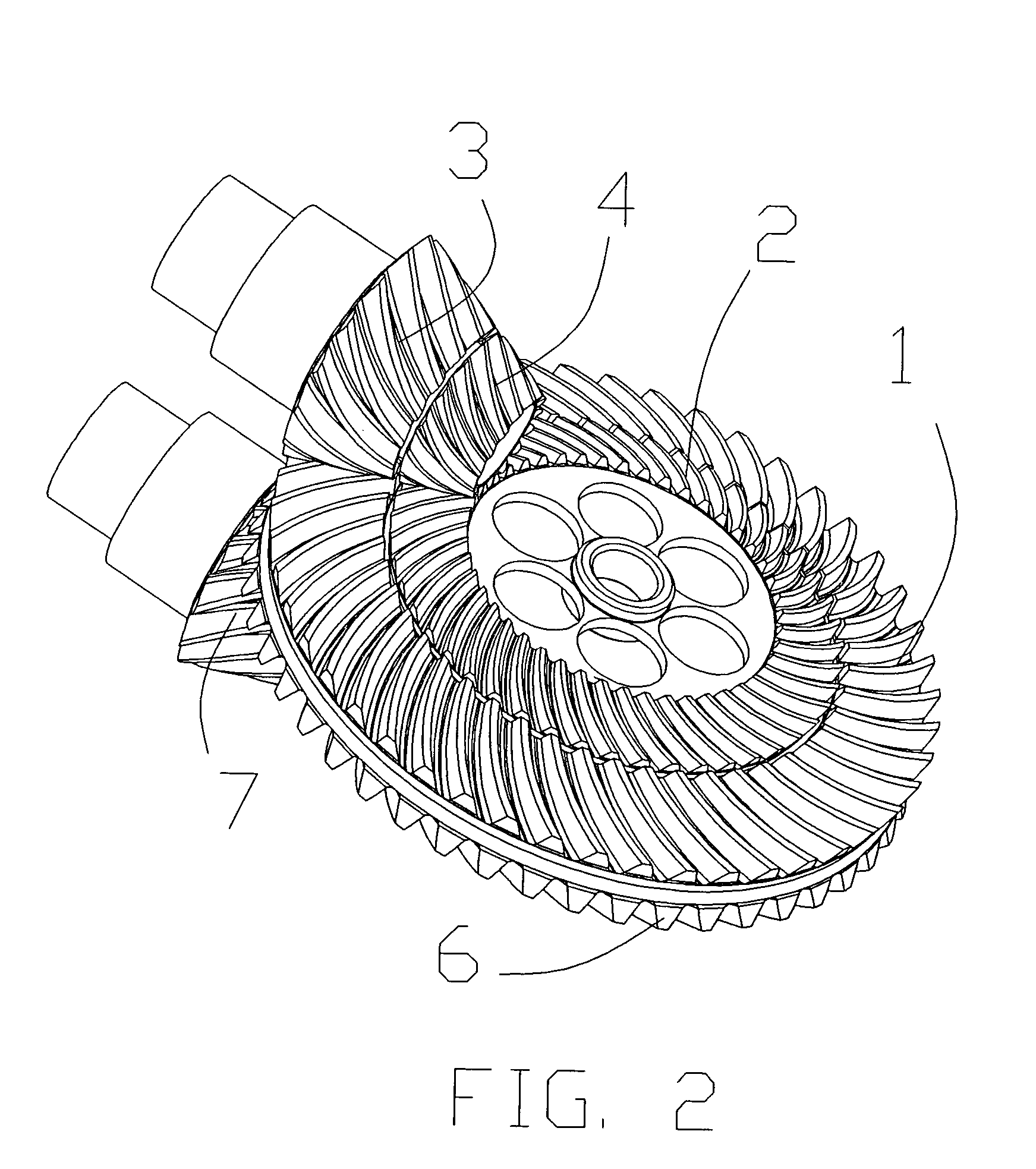

[0036] The following discussion relating to FIGS. 1-28 provides a detailed description of the unique gear reduction unit which can be utilized with the present invention. More torque capacity is the main advantage for using the right angle gears. For various torque capacities and design requirements different right angle gear sets could be used. Spiral bevel gears and hypoid gears are bevel type right angle gears. In pair of gears a pinion is a gear with less or equal number of gear teeth. Gears shown in schematic view could be bevel type (spiral bevel or hypoid) or face gear with regular worm or enveloping worm having threads with less than 90 degrees of revolution.

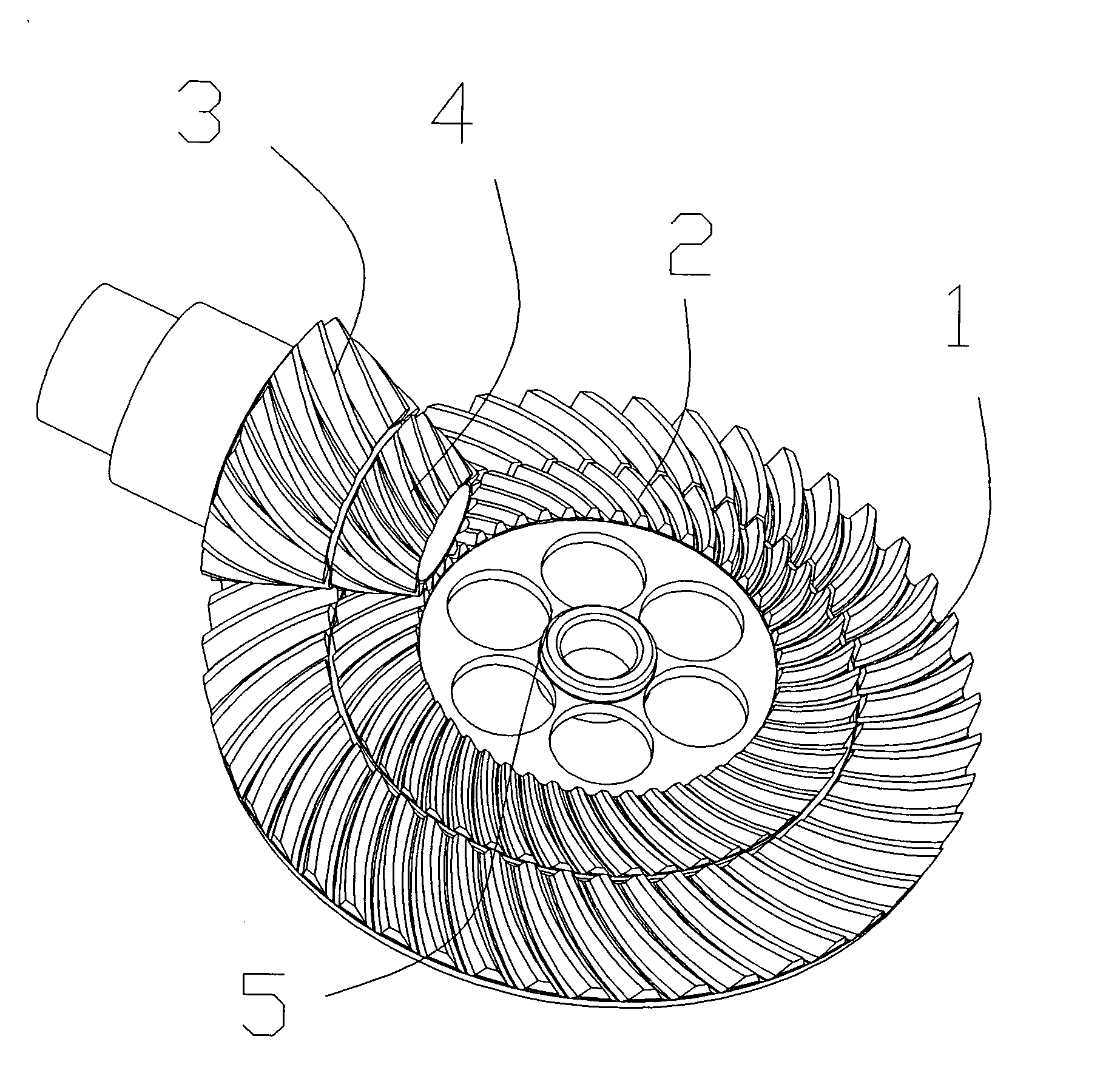

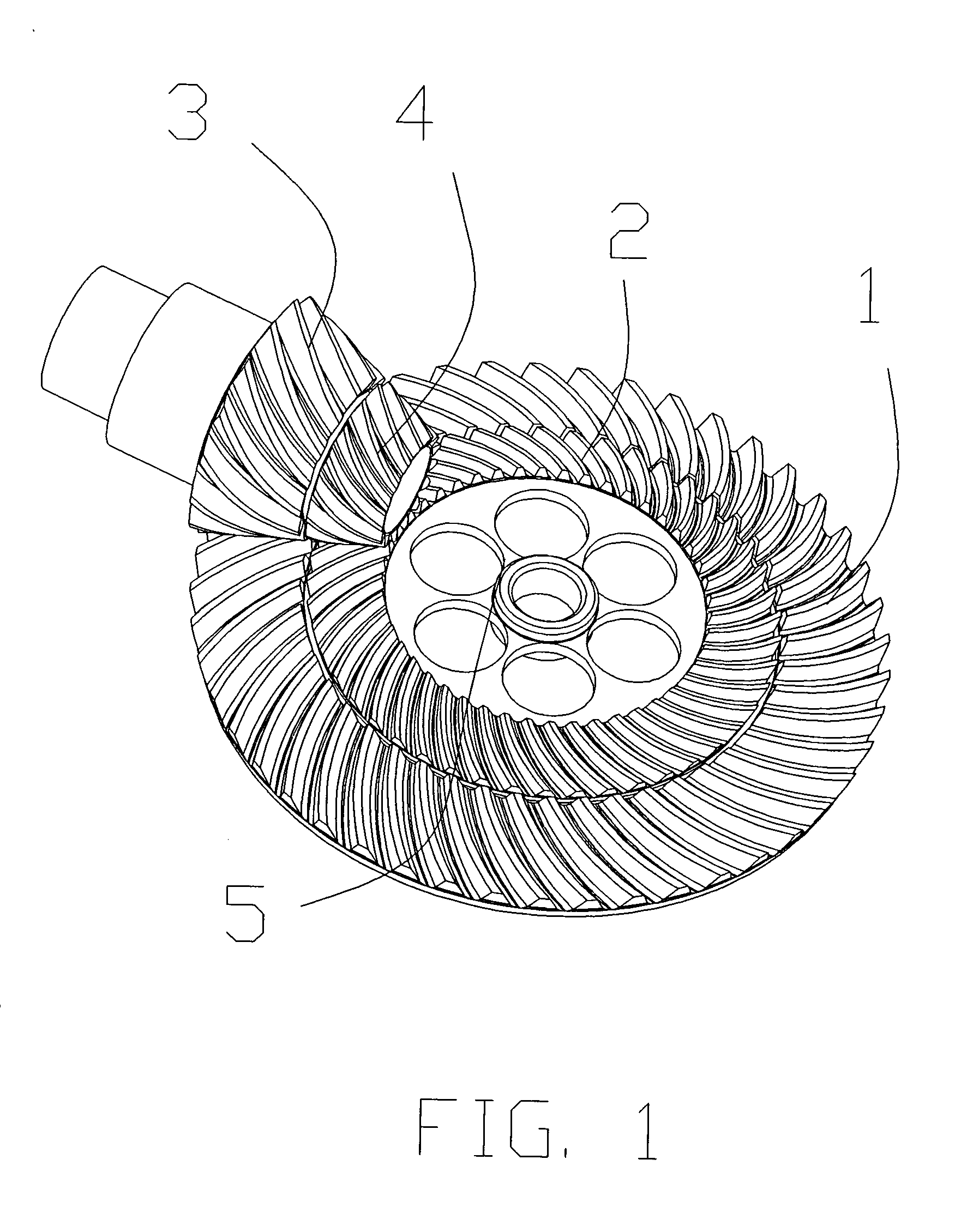

[0037]FIG. 1 is an isometric view of coaxially mounded first spiral bevel 1 and second spiral bevel gears 2 gears in mesh with coaxially mounded first pinion 3 and second pinion 4. Gears 1 and 2 are connected to each other. Output member 5 of gears 1 and 2 may be linked to a source of mechanical energy or to a load. Pinion

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap