Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Tantalum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tantalum is a chemical element with the symbol Ta and atomic number 73. Previously known as tantalium, its name comes from Tantalus, a villain from Greek mythology. Tantalum is a rare, hard, blue-gray, lustrous transition metal that is highly corrosion-resistant. It is part of the refractory metals group, which are widely used as minor components in alloys. The chemical inertness of tantalum makes it a valuable substance for laboratory equipment and a substitute for platinum. Its main use today is in tantalum capacitors in electronic equipment such as mobile phones, DVD players, video game systems and computers. Tantalum, always together with the chemically similar niobium, occurs in the mineral groups tantalite, columbite and coltan (a mix of columbite and tantalite, though not recognised as a separate mineral species). Tantalum is considered a technology-critical element.

Preparation method of iron-tantalum alloy powder, iron-tantalum alloy powder and application

ActiveCN112059195AHigh purityDense highTransportation and packagingMetal-working apparatusAlloyUltimate tensile strength

The invention relates to a preparation method of iron-tantalum alloy powder, the iron-tantalum alloy powder and application. The preparation method of the iron-tantalum alloy powder comprises the steps: firstly, an iron material and a tantalum material are prepared according to the target atom proportion and mixed; then a mixture is completely molten at the temperature of 1542-1600 DEG C; and thenatomization is conducted under the action of inert gas, and the iron-tantalum alloy powder is obtained. According to the preparation method, the melting temperature of the iron-tantalum mixture is controlled to be 1542-1600 DEG C, the atomization condition is optimized, the purity of the prepared iron-tantalum alloy powder is larger than or equal to 99.95%, the oxygen content is smaller than or equal to 600 ppm, and the iron-tantalum alloy powder with the particle size smaller than 150 meshes is obtained through screening; and an iron-cobalt-tantalum alloy sputtering target material with thehigh purity, high compactness, the high bending strength and the qualified magnetic flux is prepared advantageously, wherein tantalum rim charge of the tantalum target material is used as the tantalummaterial for preparation, so that waste is turned into wealth.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

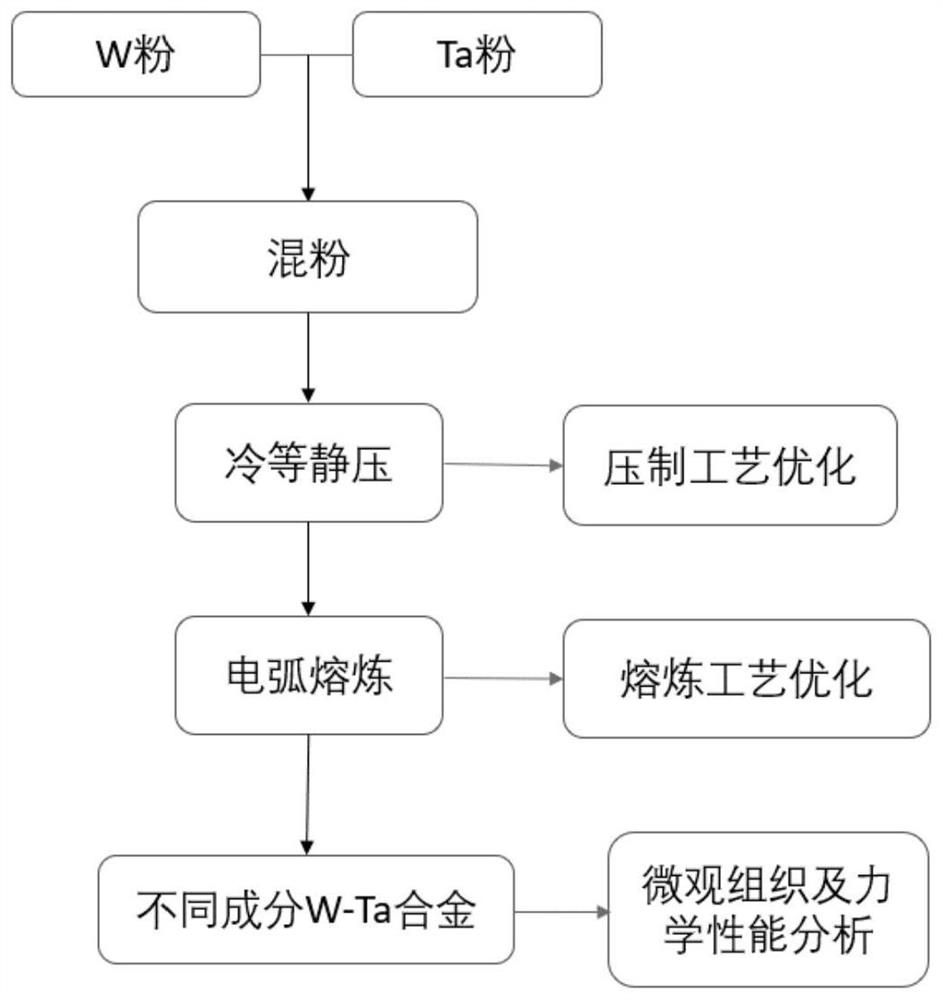

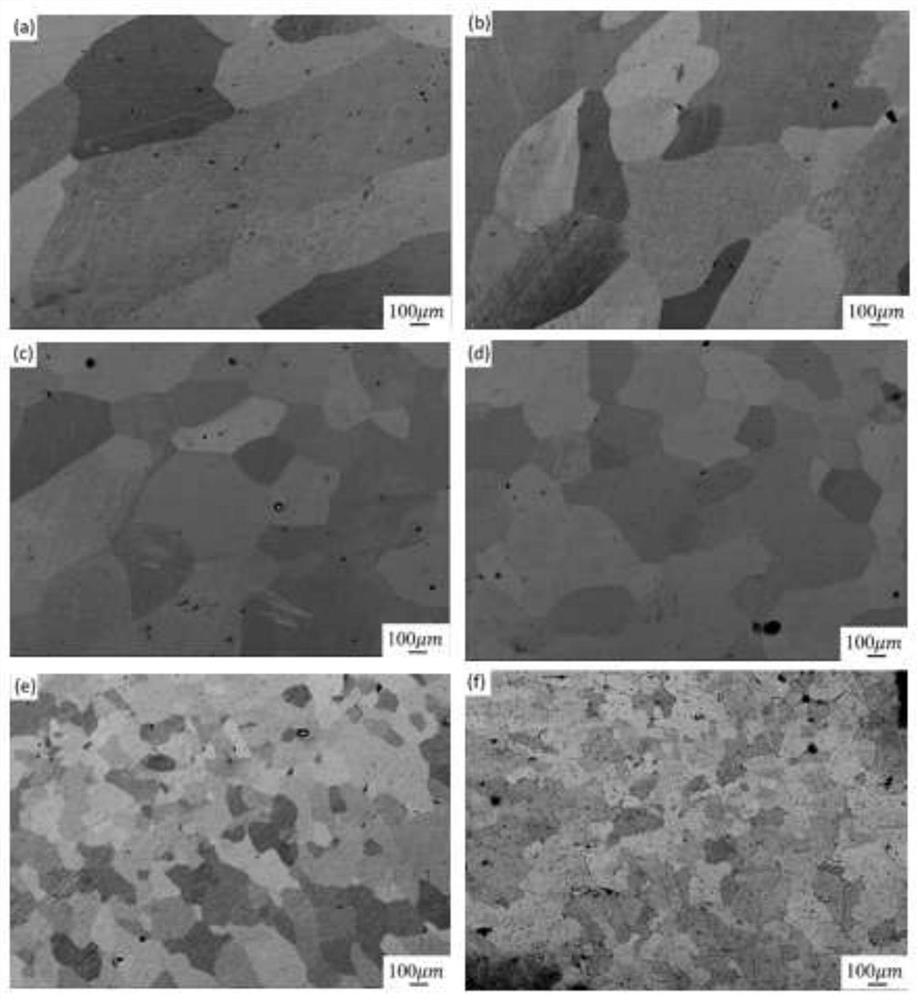

Short-process non-consumable arc melting preparation method of high-density high-melting-point tungsten alloy

ActiveCN113088718AShort manufacturing processImprove production efficiencyTransportation and packagingMetal-working apparatusArc meltingTantalum

Owner:CENT SOUTH UNIV

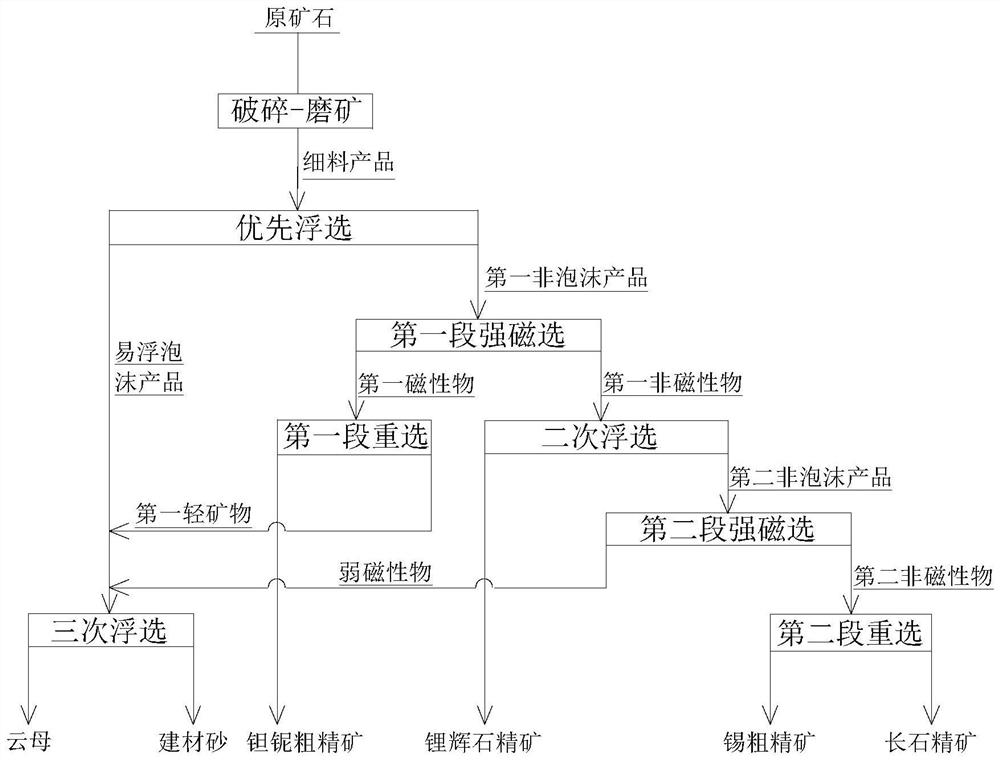

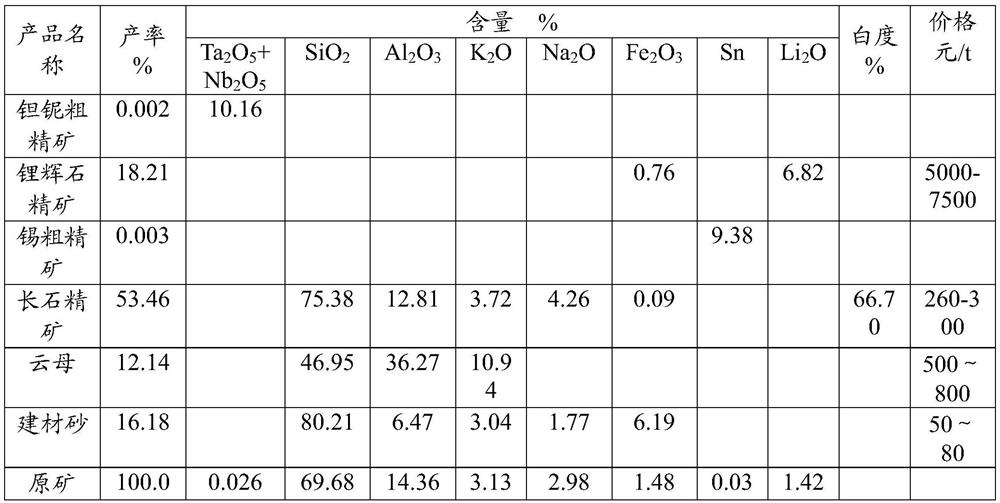

Comprehensive utilization method of pegmatite containing tantalum niobium, cassiterite, feldspar and spodumene

PendingCN114588998AImprove recycling ratesTake advantage ofHigh gradient magnetic separationFlotationNiobiumMagnetic separation

Owner:SHANDONG HUATE MAGNET TECH

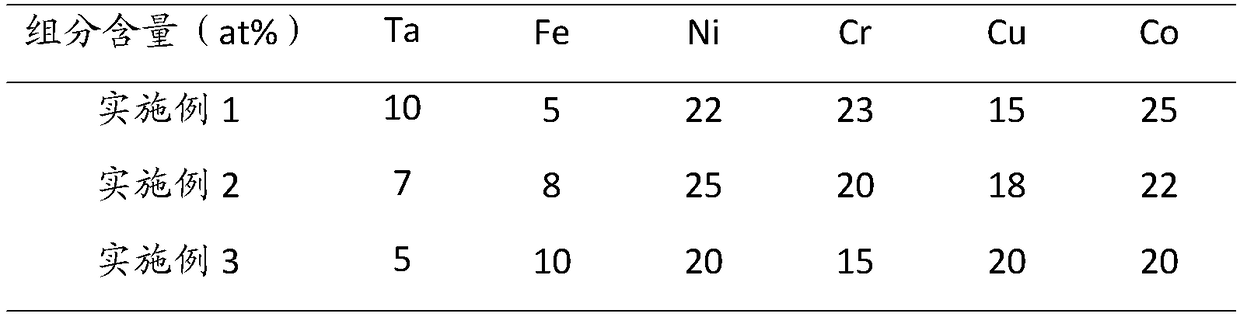

Intermediate layer alloy applied to resistance spot-welding of tantalum Ta1 and Q235 and preparation method thereof

ActiveCN109202244AImprove matchImproved comprehensive mechanical properties of jointsWelding/cutting media/materialsWelding/soldering/cutting articlesElectrical resistance and conductanceSpot welding

Owner:XIAN UNIV OF TECH

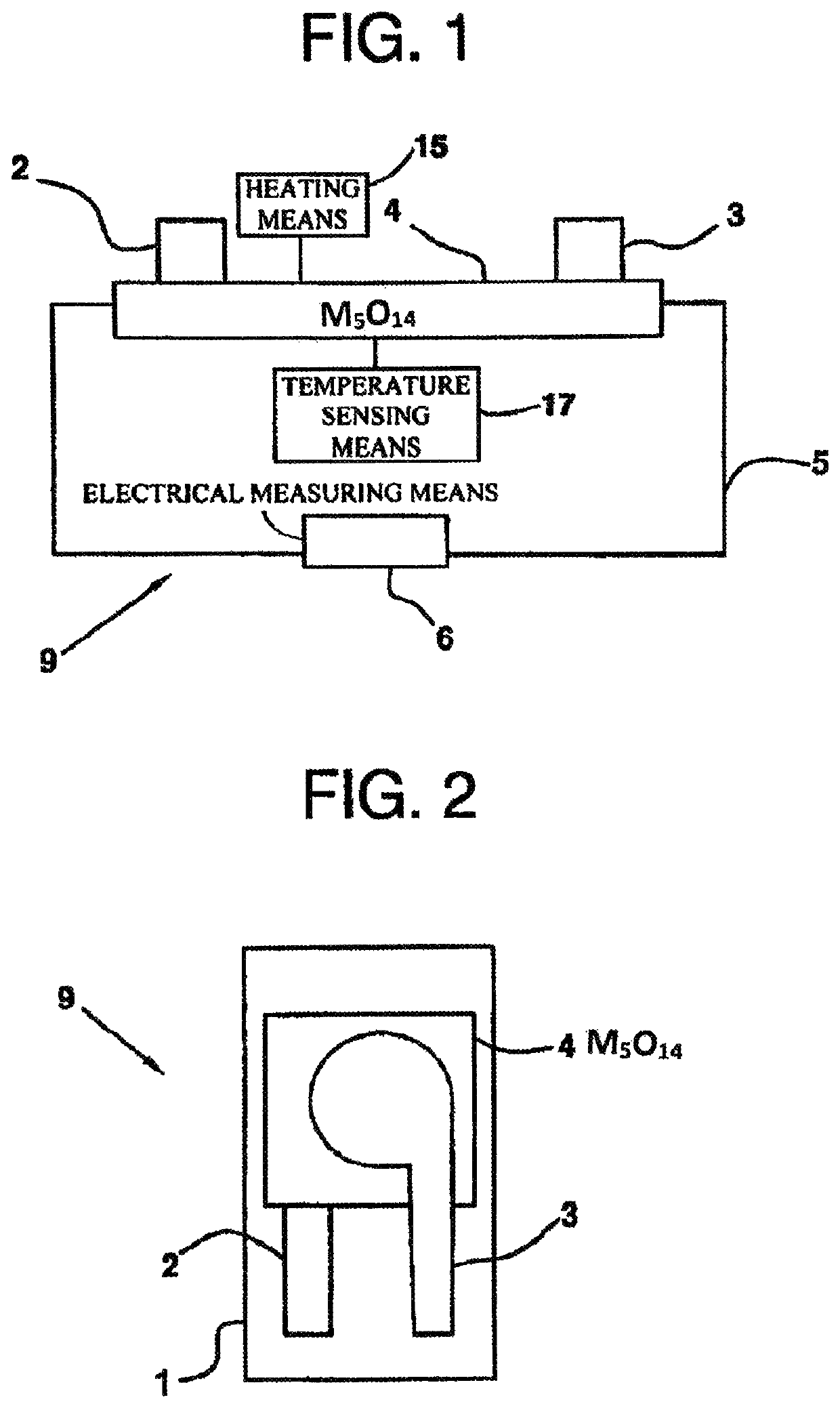

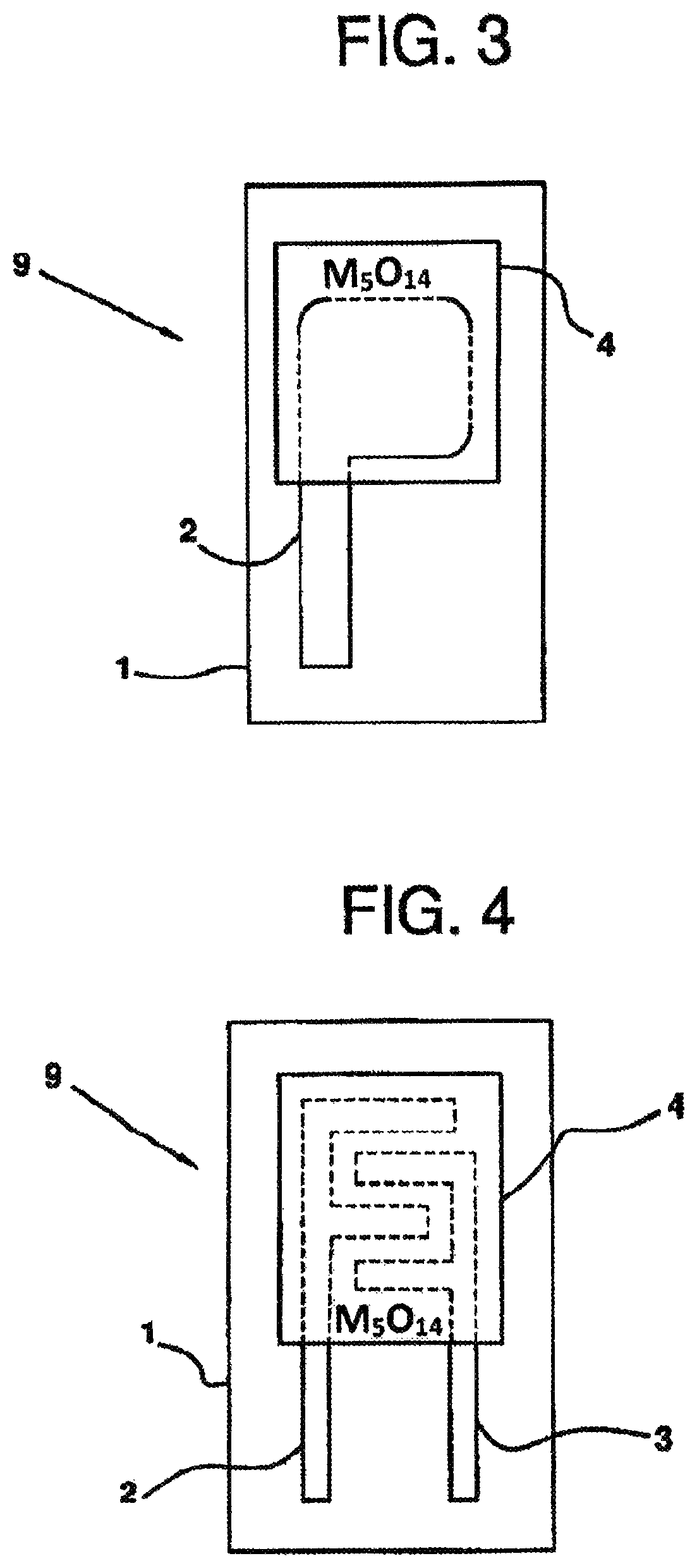

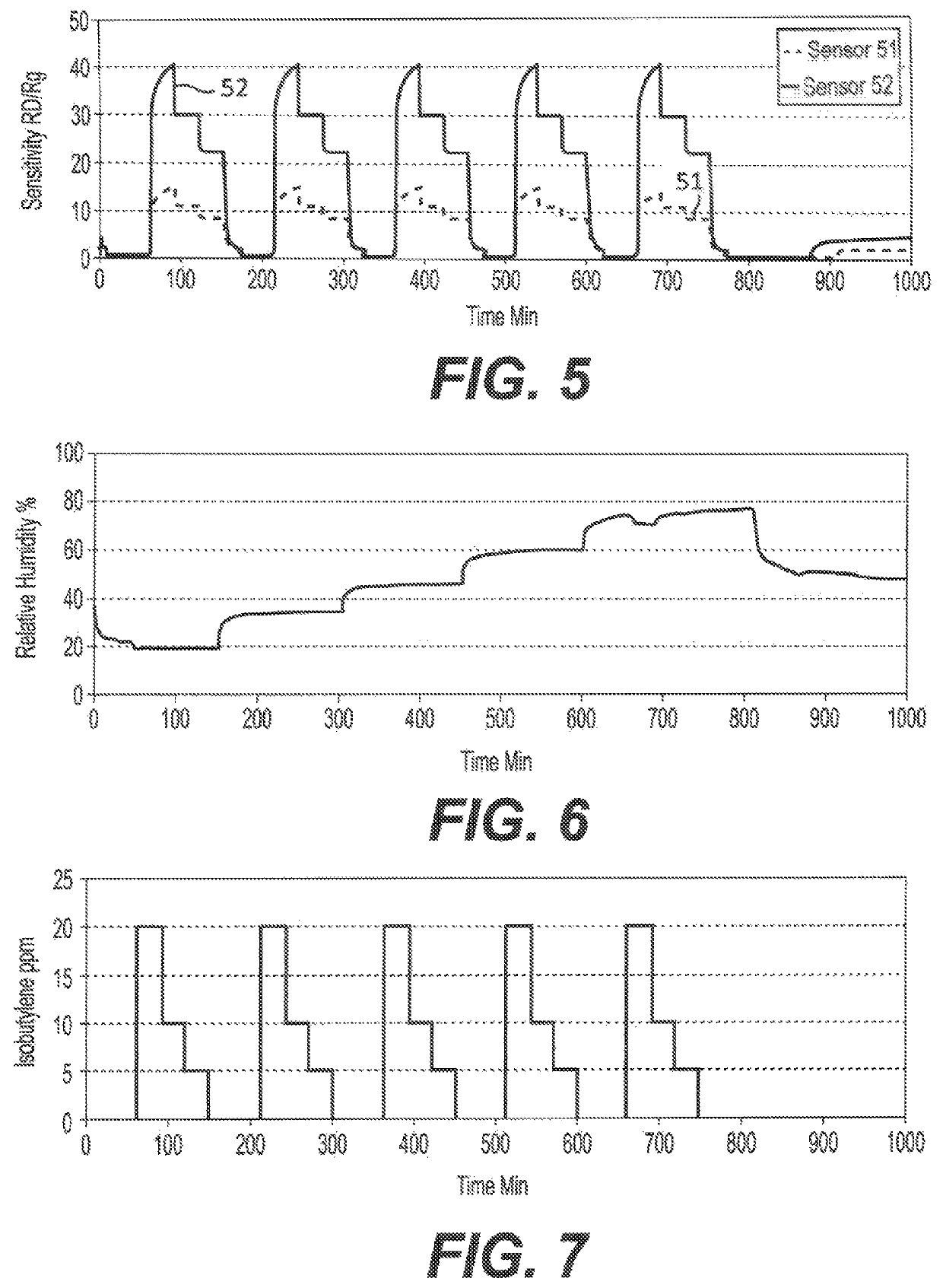

Highly effective sensor for the vapors of volatile organic compounds

ActiveUS11327040B1Exceptional sensitivityMaterial resistanceMaterial capacitancePhysical chemistryVanadium atom

Owner:ALPHASENSE LTD

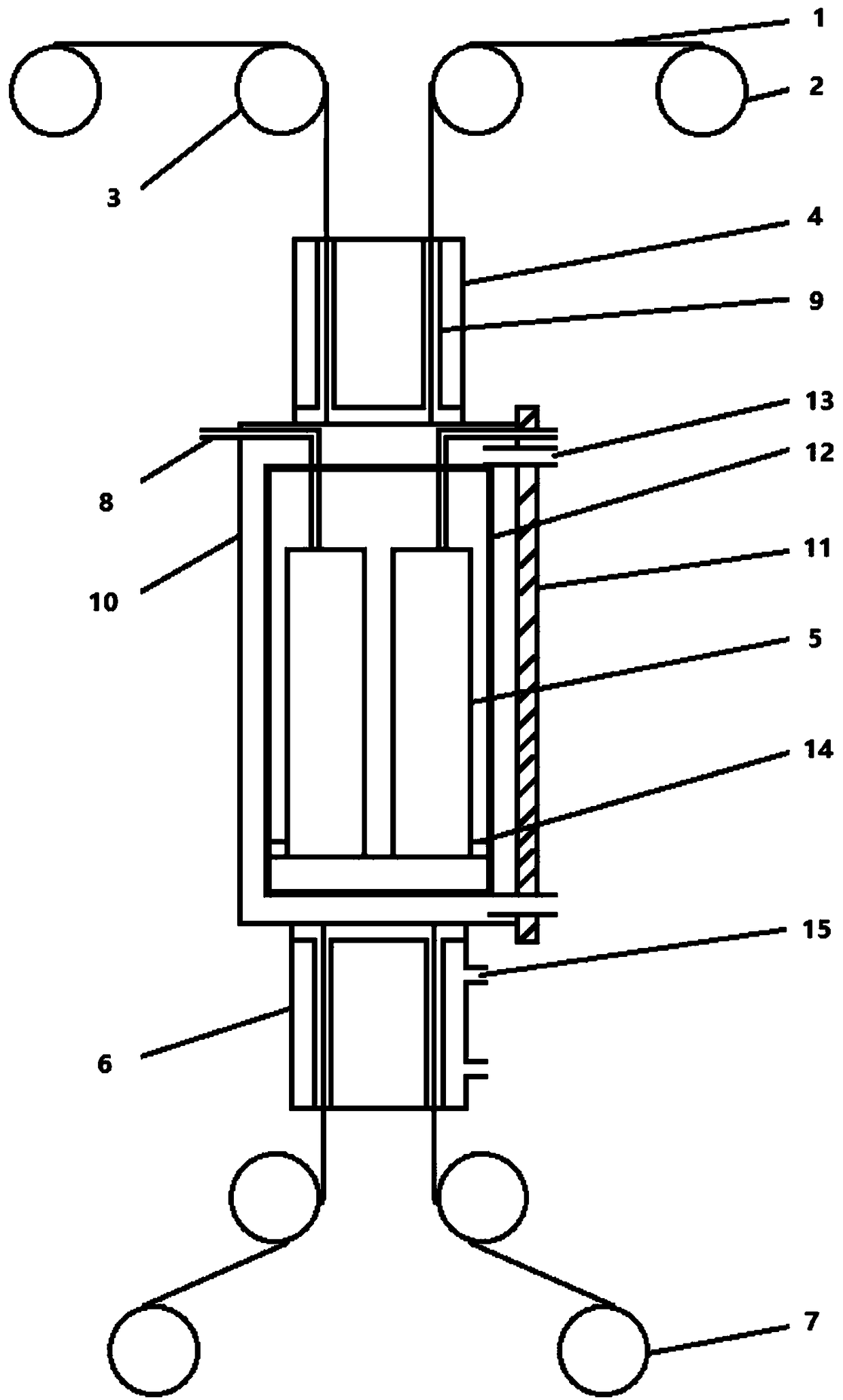

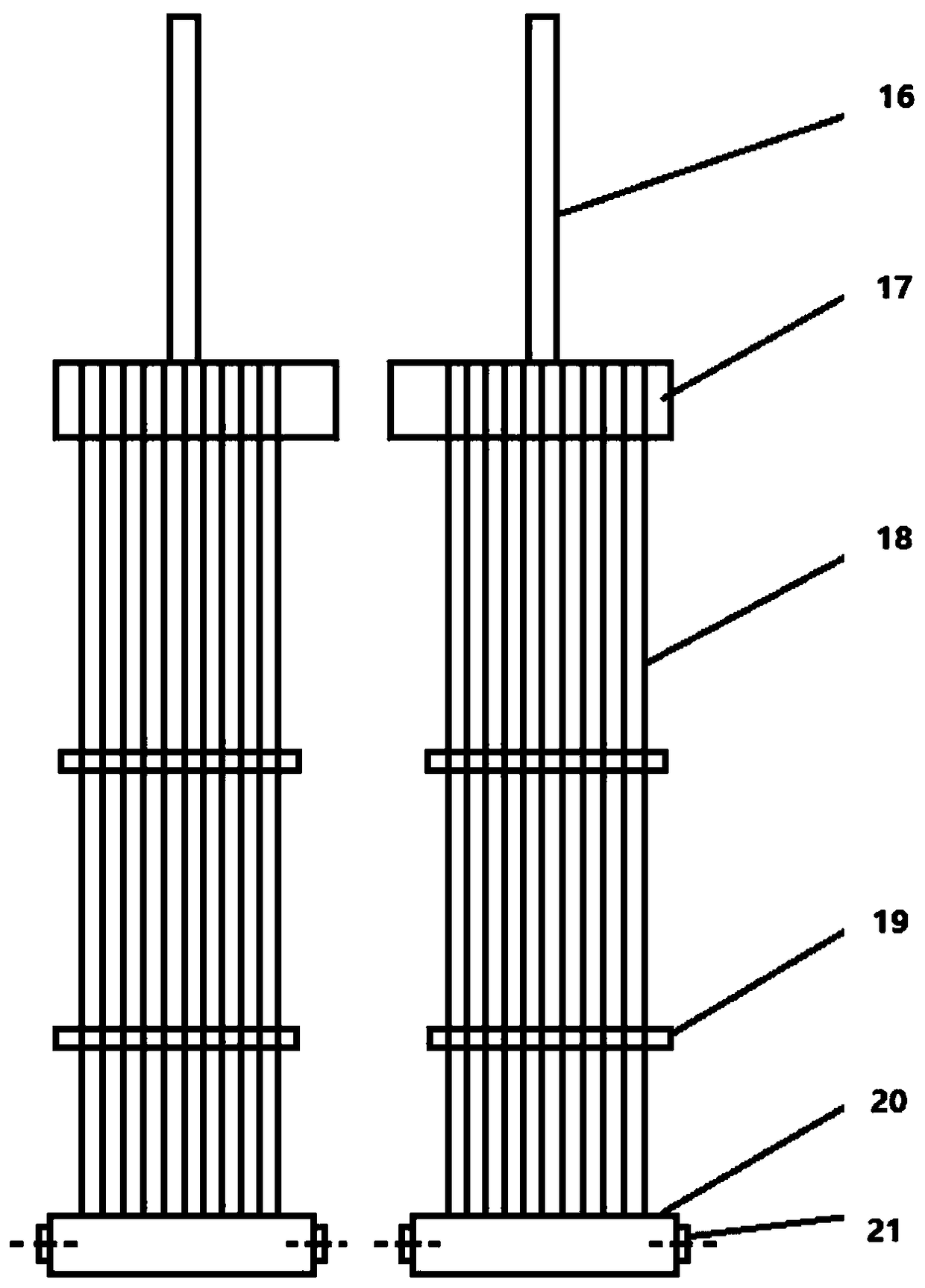

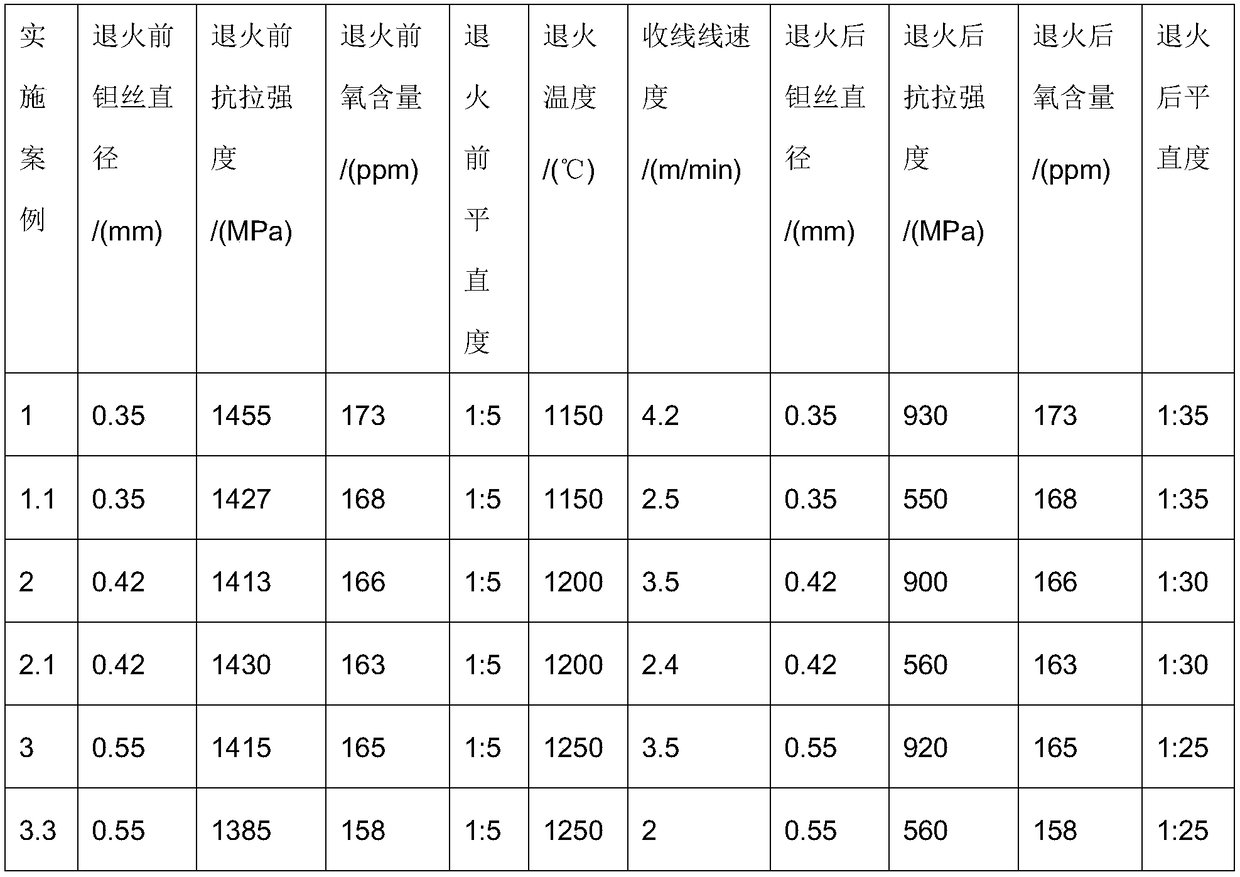

Device and method for manufacturing semi-hard or soft tantalum wire

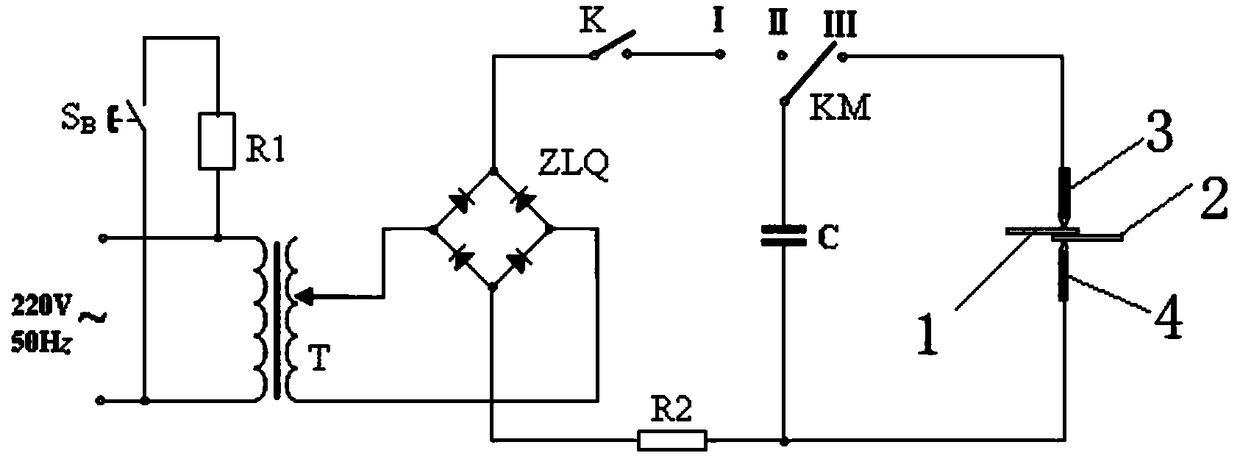

ActiveCN109280762AGuaranteed not to be oxidizedIncrease productivityFurnace typesHeat treatment furnacesElectrical resistance and conductanceConductor Coil

Owner:江门富祥电子材料有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap