Device and method for manufacturing semi-hard or soft tantalum wire

A semi-hard, tantalum wire technology, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of low flatness and difficult to straighten tantalum wire, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

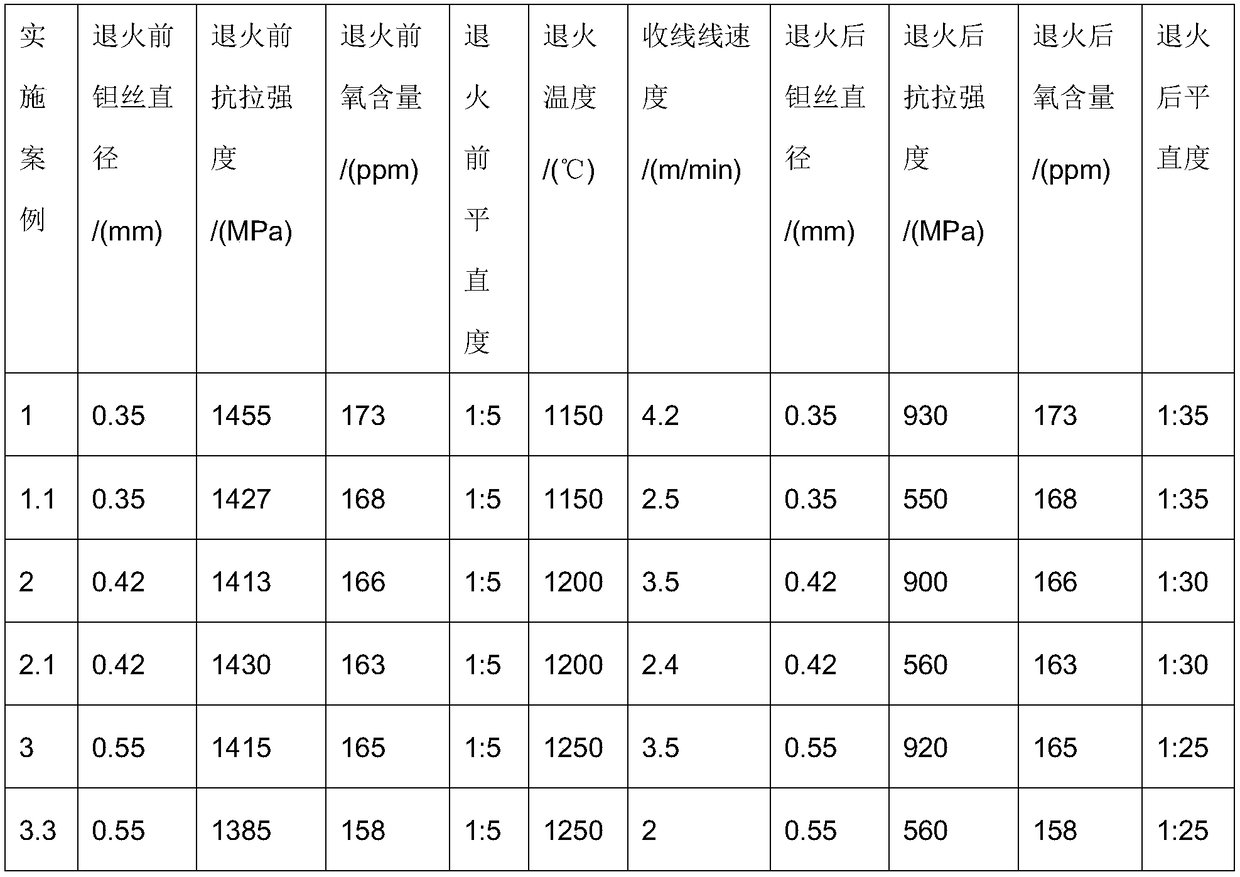

Examples

Embodiment Construction

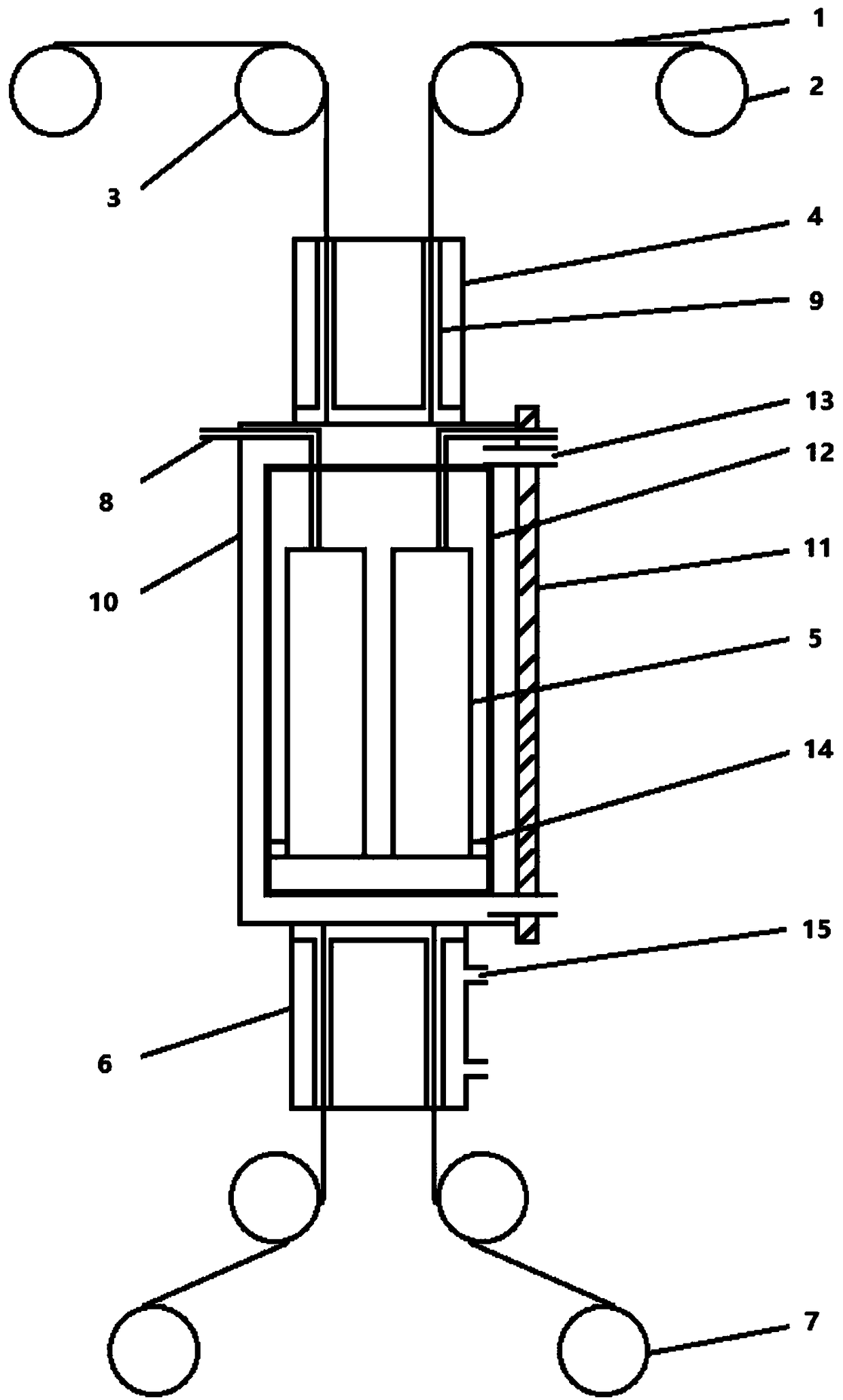

[0020] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 Shown, a kind of device that is used to manufacture semi-hard state or soft tantalum wire, described device comprises wire-off device, annealing device and take-up device; The guide wheel 3, the wire take-up device includes a wire take-up wheel 7 and a guide wheel positioned at the exit of the annealing device;

[0021] The annealing device comprises an upper guide box 4, an incubator 10 and a lower guide box 6 successively from top to bottom, and an inner conduit 9 is arranged in the upper guide box 4 and the lower guide box 6; the length of the upper guide box 4 is about 500mm, the length of the wall cabinet heater 5 is about 500mm, because it takes a long time to cool after annealing, so the length of the lower guide box 6 is ≥ 1000mm; the lower guide box has a cooling water pipe;

[0022] Described incubator has cooling water pipe 13 and incubator door 11, and i

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap