Loaded metallocene catalyst and preparation method thereof

A technology of metallocene catalysts and metallocene compounds, applied in the field of supported metallocene catalysts and their preparation, to achieve high catalytic efficiency, low cost, and simple and easy preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] This example is used to illustrate the supported metallocene catalyst and its preparation method according to the present invention.

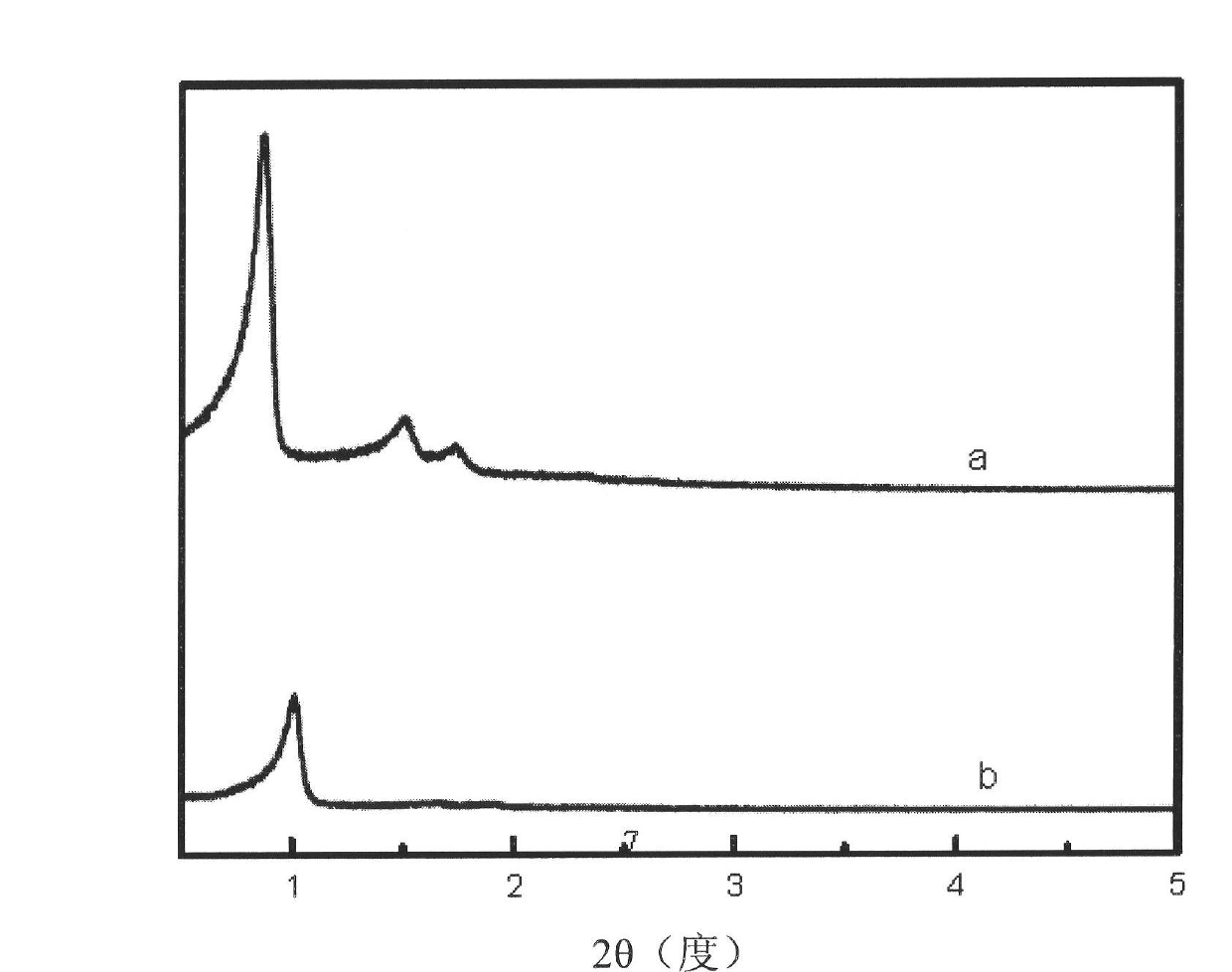

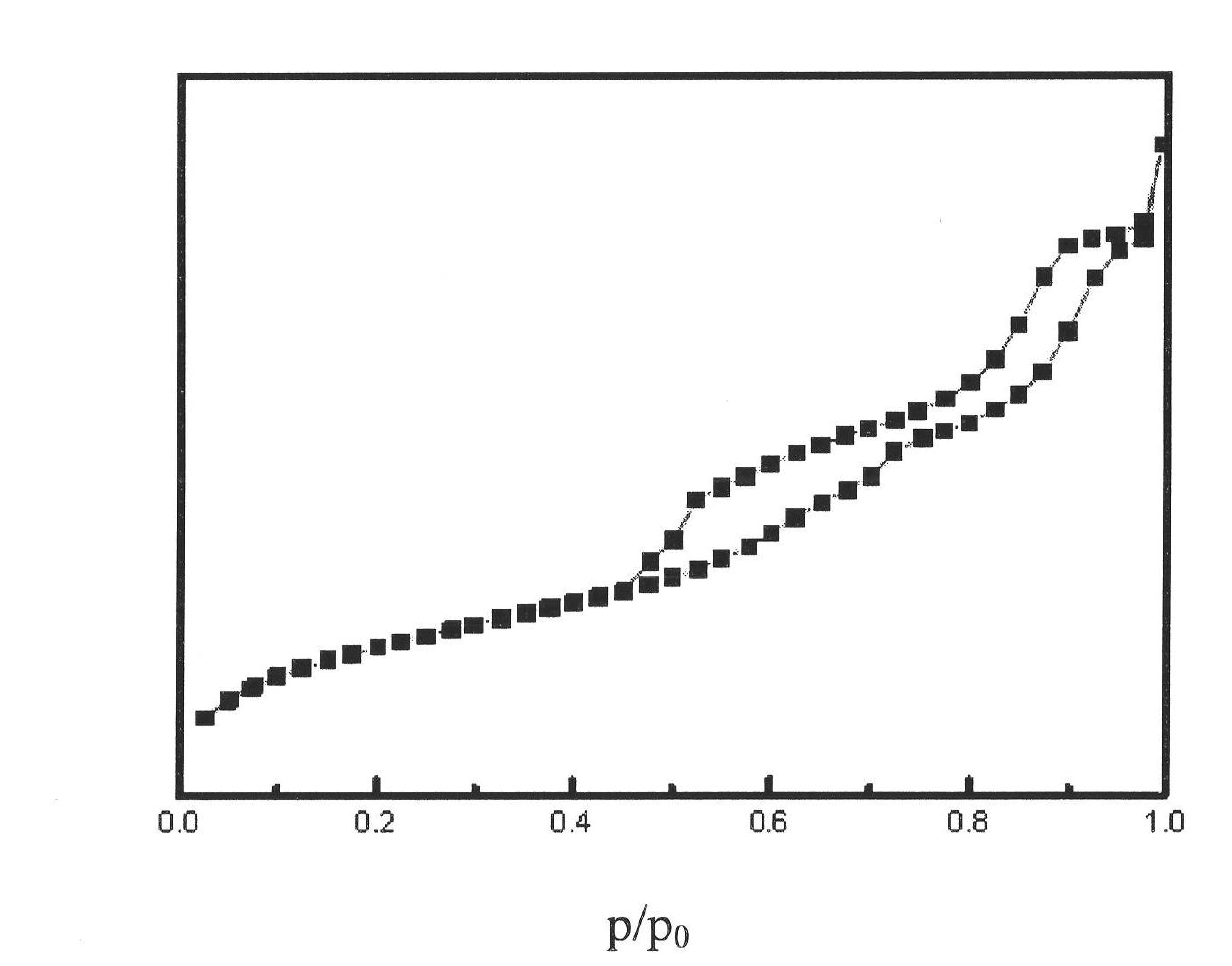

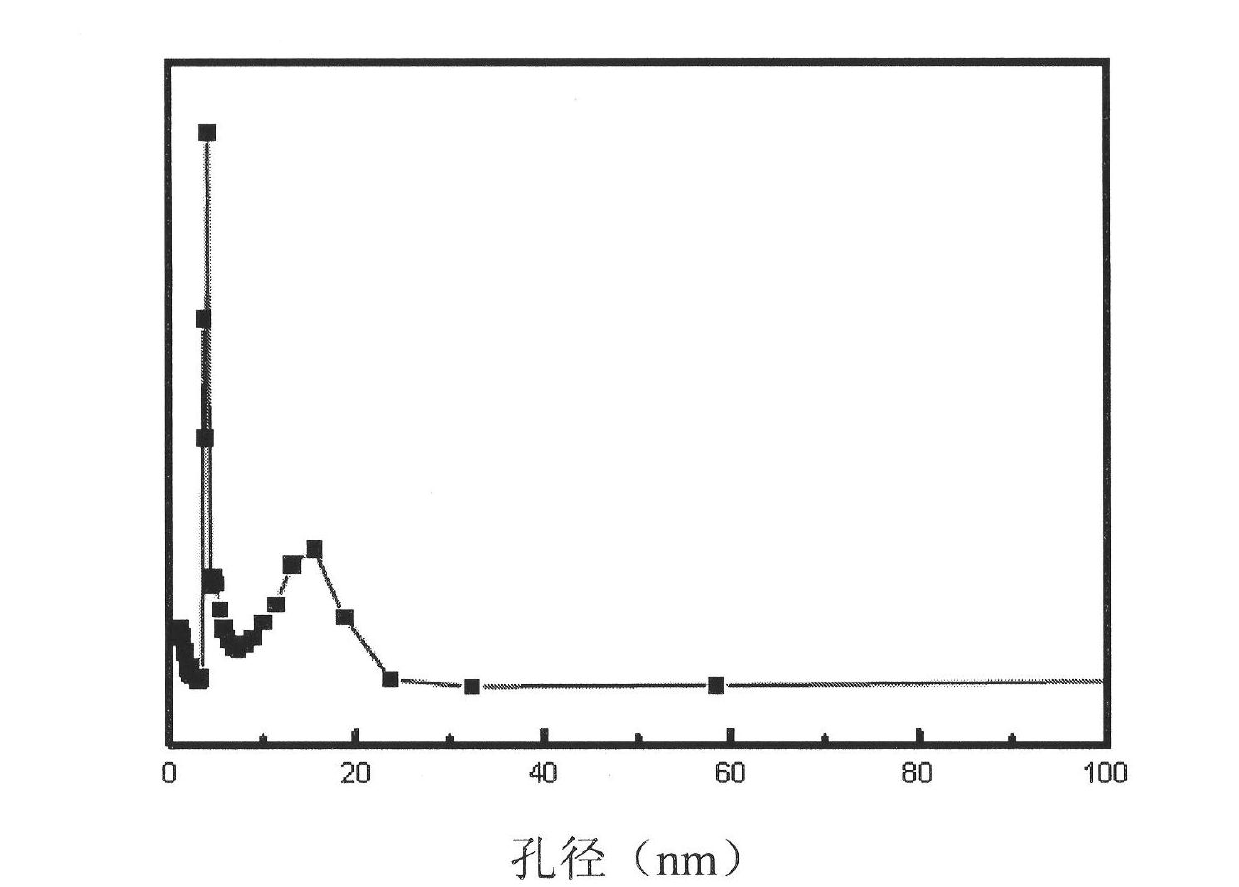

[0064] SBA-15 (commercially purchased from Jilin University High-Tech Co., Ltd., Changchun, Jilin) and silica gel 955 (purchased from Shandong Lianke Silica Co., Ltd., with an average diameter of 20 microns and a specific surface area of 250m 2 / g) calcined at 400°C for 10 hours under the protection of nitrogen at a weight ratio of 1:2 to remove hydroxyl groups and residual moisture, thereby obtaining a carrier (named SBA-15-955-1);

[0065] Transfer 1.14 g of SBA-15-955-1 to a 250 ml glass reactor fully replaced by nitrogen, add 10 ml of refined toluene (refluxing with sodium for 24 hours before toluene is used) and 1.14 g of methylalumoxane ( commercially available from Albemarle, USA), and stirred at 50° C. for 4 hours. After the reaction was completed, let it stand, and filter out the liquid after the layers were separated, and w

experiment Embodiment 1

[0075] This experimental example is used to illustrate the catalytic efficiency of the supported metallocene catalyst according to the present invention.

[0076] In a 2-liter stainless steel autoclave, replace three times each with nitrogen and ethylene, then add 200 ml of hexane, raise the temperature of the kettle to 80 ° C, then add 800 ml of hexane, and add 2 ml of hexane with the addition of hexane 1 mol / liter triethylaluminum (TEA) hexane solution, then add 61 mg of SBA-15-955-BU-1, continue to feed ethylene to raise the pressure to 1.0MPa and maintain it at 1.0MPa, and react at 70°C 1 hour. Obtain 334 grams of polyethylene particle powder, the bulk density (BD) of this polyethylene particle powder is 0.336g / mL, melt index MI 2.16 = 0.069 g / 10 min. It is determined by calculation that the efficiency of the catalyst is 5475gPE / (gcat h) (ie, 1.06×10 8 g PE / (molZr h)).

experiment Embodiment 2

[0078] This experimental example is used to illustrate the catalytic efficiency of the supported metallocene catalyst according to the present invention.

[0079] In a 2-liter stainless steel autoclave, replace three times each with nitrogen and ethylene, then add 200 ml of hexane, raise the temperature of the kettle to 80 ° C, then add 800 ml of hexane, and add 2 ml of hexane with the addition of hexane 1 mol / L of triethylaluminum (commercially purchased from Zhejiang Freed Chemical Co., Ltd.) hexane solution and 10 mL of hexene, followed by adding 40.3 mg of SBA-15-955-BU-1, raising the ethylene pressure to 1.0 MPa was maintained at 1.0 MPa, and reacted at 70°C for 1 hour. Obtain 220 grams of polymkeric substance, the bulk density (BD) of this polymkeric substance is 0.306g / mL, melt index MI 2.16 = 0.405 g / 10 min. It was determined by calculation that the efficiency of the catalyst was 5459g PE / (gcat h) (ie, 1.06×10 8 gPE / (molZr h)).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap