Preparation method of perovskite structure lead titanate single crystal nanoparticles

A phase lead titanate, single crystal nanotechnology, applied in the field of preparation of perovskite phase lead titanate single crystal nanoparticles, can solve the chemical composition lead volatilization deviation, serious lead titanate agglomeration, difficult to control lead titanate particles Shape and other problems, to achieve the effect of no pollution, low cost and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

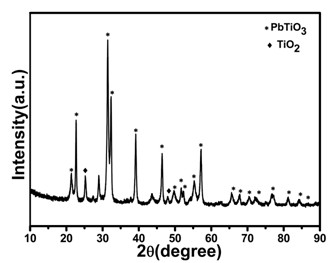

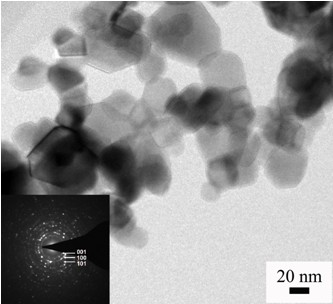

Image

Examples

Embodiment 1

[0017] 1) Dissolve titanium dioxide in 6 mol / L potassium hydroxide aqueous solution to adjust Ti 4+ The concentration is 0.01mol / L;

[0018] 2) Under stirring, add Pb dropwise to the titanium dioxide alkaline solution prepared in step 1) 2+ An aqueous lead nitrate solution with an ion concentration of 0.01 mol / L was stirred for 2 hours to obtain an oxyhydroxide suspension of titanium and lead;

[0019] 3) Add the suspended liquid prepared in step 2) into the inner tank of the reactor, use deionized water to adjust the volume of the reaction material in the inner tank of the reactor to 80% of the volume of the inner tank of the reactor, stir for 5 minutes, and titanium The oxyhydroxide molar concentration is 0.1mol / L, the potassium hydroxide molar concentration is 6mol / L, the molar ratio of lead and titanium is 1.0, and the volume basis of the molar concentration is the total volume of the precursor slurry;

[0020] 4) Put the reactor liner equipped with reaction mater

Embodiment 2

[0023] 1) Dissolve titanium dioxide in 6 mol / L potassium hydroxide aqueous solution to adjust Ti 4+ The concentration is 0.05mol / L;

[0024] 2) Under stirring, add Pb dropwise to the titanium dioxide alkaline solution prepared in step 1) 2+ An aqueous lead nitrate solution with an ion concentration of 0.0625 mol / L was stirred for 2 hours to obtain an oxyhydroxide suspension of titanium and lead;

[0025] 3) Add the suspended liquid prepared in step 2) into the inner tank of the reactor, use deionized water to adjust the volume of the reaction material in the inner tank of the reactor to 80% of the volume of the inner tank of the reactor, stir for 5 minutes, and titanium The oxyhydroxide molar concentration is 0.1mol / L, the potassium hydroxide molar concentration is 6mol / L, the molar ratio of lead and titanium is 1.25, and the volume base of the molar concentration is the total volume of the precursor slurry;

[0026] 4) Place the reactor liner equipped with reaction m

Embodiment 3

[0029] 1) Dissolve titanium dioxide in 6 mol / L potassium hydroxide aqueous solution to adjust Ti 4+ The concentration is 0.2mol / L;

[0030] 2) Under stirring, add Pb dropwise to the titanium dioxide alkaline solution prepared in step 1) 2+ An aqueous lead nitrate solution with an ion concentration of 0.2 mol / L was stirred for 2 hours to obtain an oxyhydroxide suspension of titanium and lead;

[0031] 3) Add the suspended liquid prepared in step 2) into the inner tank of the reactor, use deionized water to adjust the volume of the reaction material in the inner tank of the reactor to 80% of the volume of the inner tank of the reactor, stir for 5 minutes, and titanium The oxyhydroxide molar concentration is 0.2mol / L, the potassium hydroxide molar concentration is 6mol / L, the molar ratio of lead and titanium is 1.0, and the volume basis of the molar concentration is the total volume of the precursor slurry;

[0032] 4) Put the reactor liner equipped with reaction materia

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap