Nickel cobalt lithium manganate composite material and preparation method thereof

A technology of nickel-cobalt lithium manganate and composite materials, applied in the field of lithium-ion batteries, can solve the problems of decreased electrical properties of materials, material structural defects, aggravated lithium volatilization, etc., to achieve high compaction density and energy density, stable material structure, Simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

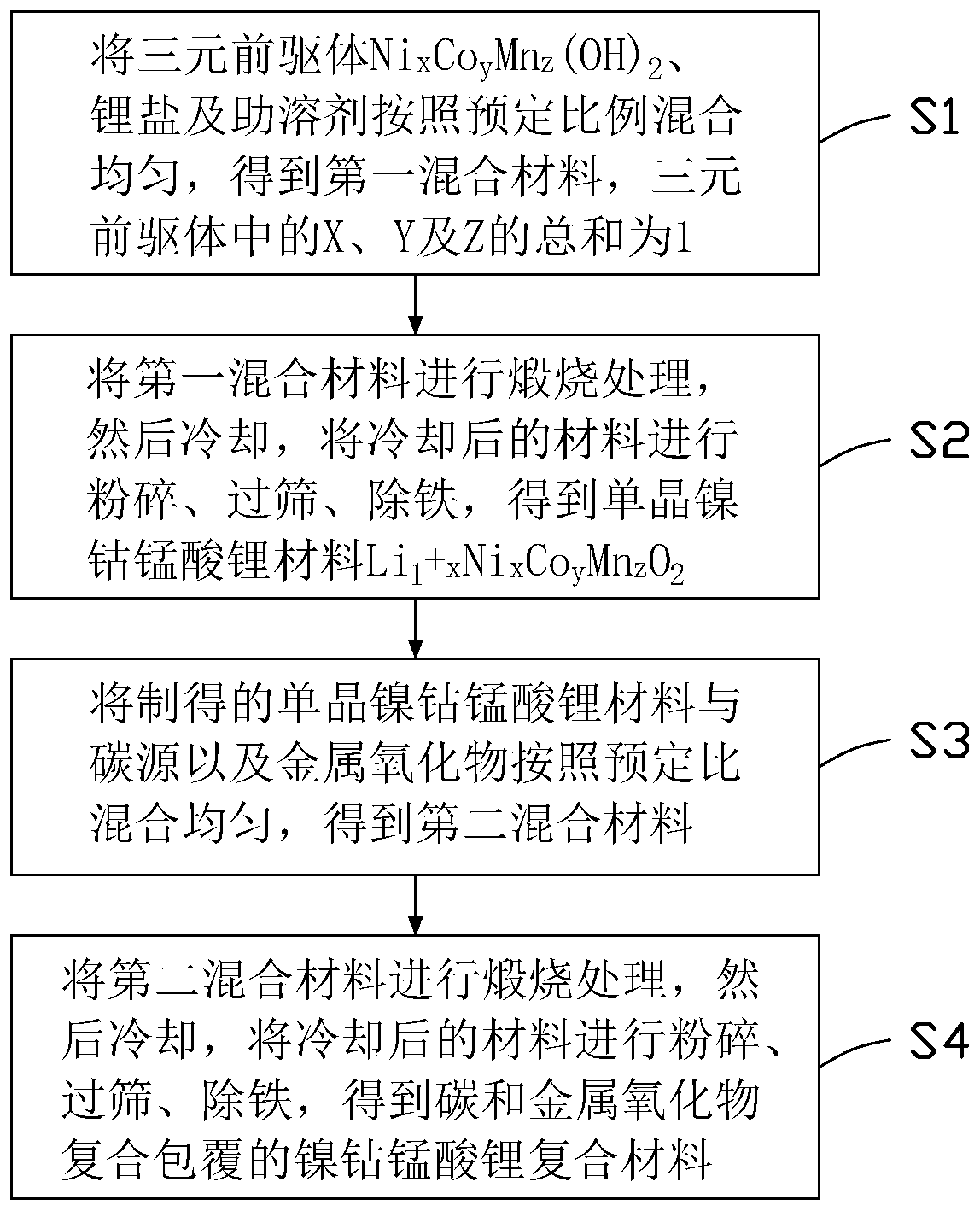

[0025] see figure 1 , figure 1 It is a schematic flow diagram of the preparation method of the nickel-cobalt lithium manganese oxide composite material in one embodiment of the present invention, specifically comprising the following steps:

[0026] S11, the ternary precursor Ni x co y mn z (OH) 2 , lithium salt and co-solvent are uniformly mixed according to a predetermined ratio to obtain a first mixed material, wherein the sum of X, Y and Z is 1;

[0027] S12, calcining the first mixed material, then cooling, pulverizing, sieving, and removing iron from the cooled material to obtain a single crystal nickel cobalt lithium manganese oxide material Li 1 + x Ni x co y mn z o 2 ;

[0028] S13, uniformly mixing the prepared single crystal nickel cobalt lithium manganese oxide material with carbon source and metal oxide according to a predetermined ratio to obtain a second mixed material;

[0029] S14, calcining the second mixed material, then cooling, pulverizing, sievin

Embodiment 1

[0044] Take 1000g ternary precursor Ni 0.5 co 0.2 mn 0.3 (OH) 2 , 431.5g of lithium carbonate and 7.1536g of boron oxide were mixed in a mixer for 4 hours, and the mixed material was put into a calciner, fed with dry air, sintered at 940°C for 20 hours and then cooled, and the cooled The material is pulverized in a small airflow machine, the particle size is controlled at 4-7μm, and then the iron is sieved to obtain a single crystal nickel cobalt lithium manganese oxide material, which is recorded as NCM-1; take 900g of the prepared single crystal nickel cobalt lithium manganese oxide material Material, 1.8g polyethylene glycol and 4.5g Al 2 o 3 Put it in a ball mill and mix it for 2 hours, put the mixed material into the calcination device, pass in nitrogen gas, sinter at 600°C for 8 hours and then cool it, pulverize the cooled material in a mechanical pulverizer, and pass through a sieve The single-crystal nickel-cobalt-lithium manganese oxide composite material coated wit

Embodiment 2

[0046] Take 1000g ternary precursor Ni 0.5 co 0.2 mn 0.3 (OH) 2 , 431.5g of lithium carbonate and 8.6291g of aluminum fluoride were mixed in a mixer for 4 hours, the mixed material was put into a calcination device, fed with dry air, sintered at 980°C for 20 hours and then cooled, and the cooled The final material is pulverized in a small airflow machine, and the particle size is controlled at 4-7 μm, and then the single crystal nickel cobalt lithium manganese oxide material is obtained by sieving iron, which is recorded as NCM-1; take 900g of the prepared single crystal nickel cobalt manganese acid Lithium material, 1.8g glucose and 4.5g ZrO 2 Put it in a ball mill and mix it for 2 hours, put the mixed material into the calcination device, pass in nitrogen gas, sinter at 500°C for 8 hours and then cool it down, pulverize the cooled material in a mechanical pulverizer, and pass through a sieve The single-crystal nickel-cobalt-lithium manganese oxide composite material coated

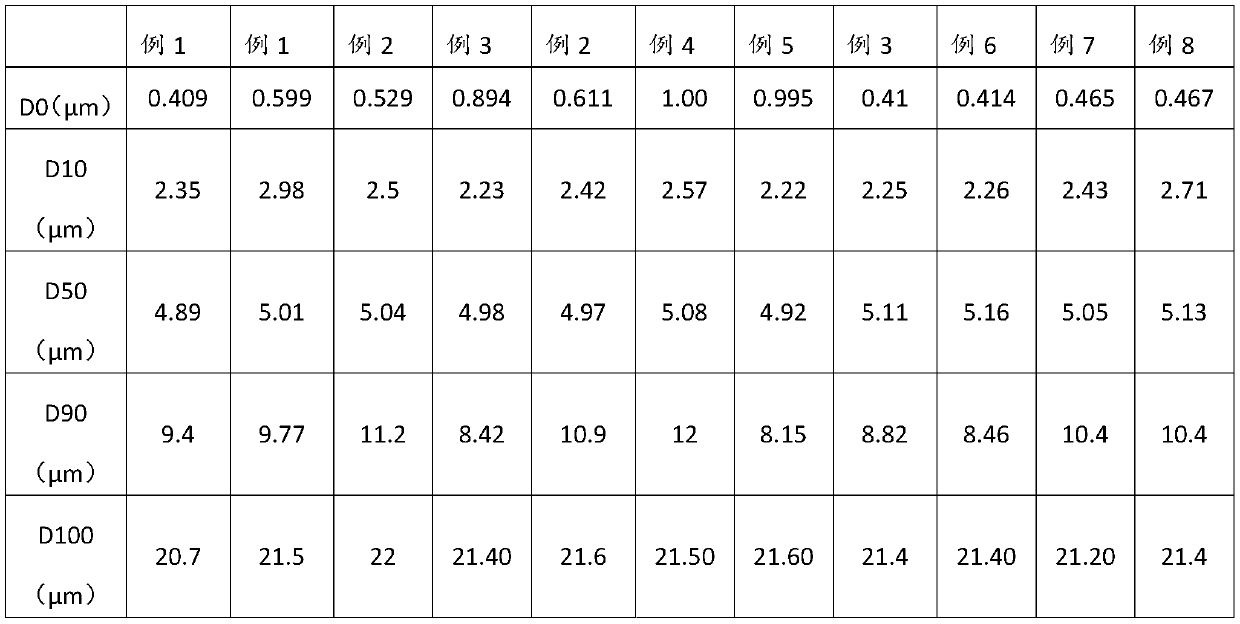

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap