Preparation method of nitrogen-doped porous carbon material

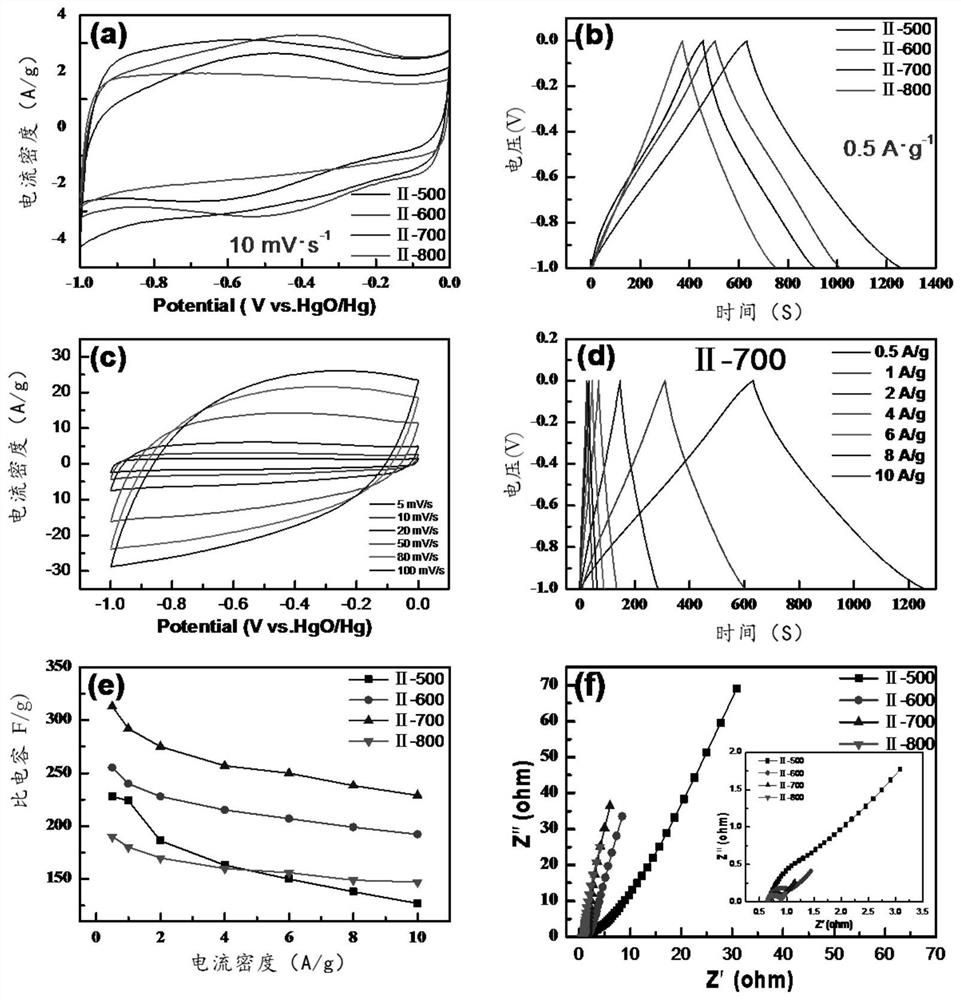

A nitrogen-doped porous carbon and nanomaterial technology, applied in nanocarbon and other directions, can solve the problems of complicated process, high equipment requirements, low product yield, etc., and achieve the effects of simple process, improved energy storage capacity, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

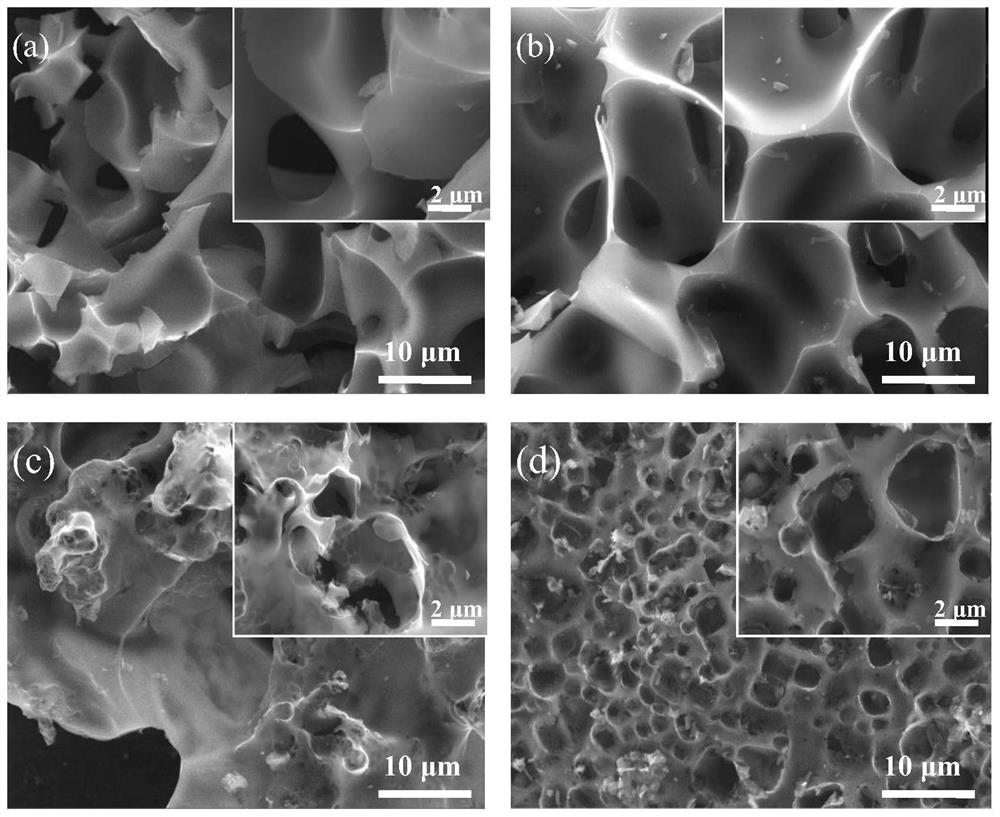

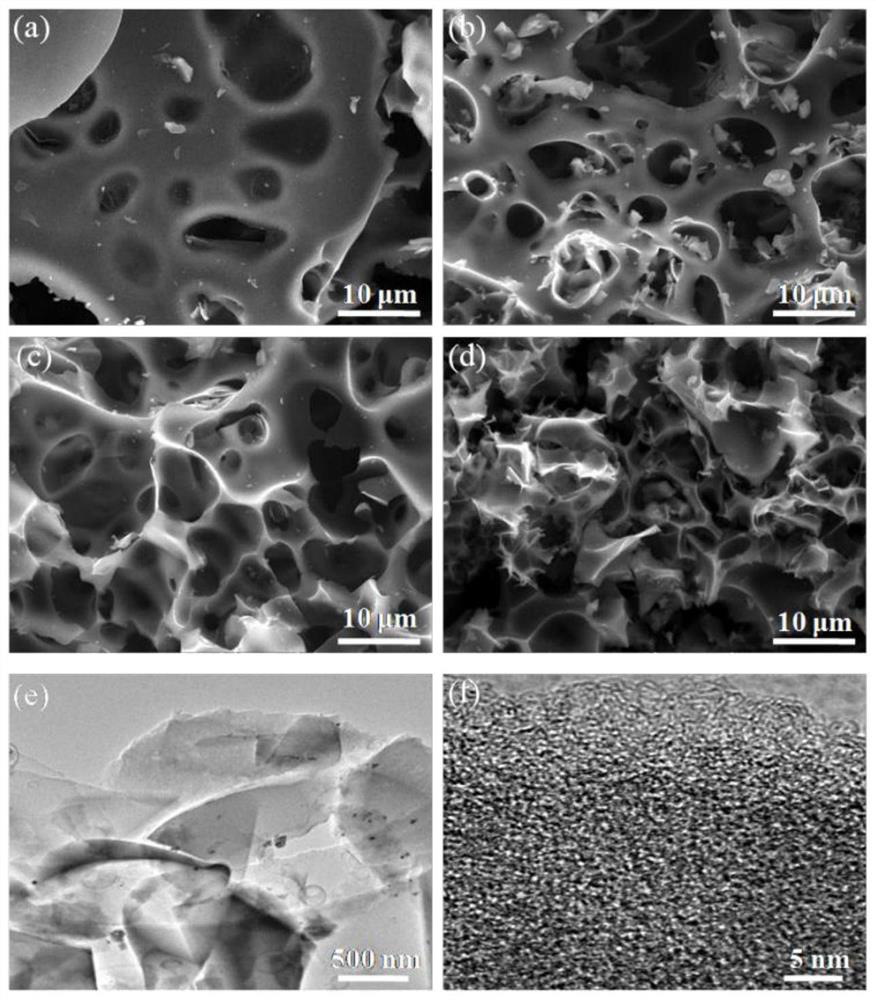

Embodiment 1

[0030] S1. Weighing 1 part by weight of tripotassium EDTA and 1 part by weight of sodium chloroacetate;

[0031] S2, the two are ground in a mortar for 15 minutes;

[0032] S3. Put it in a tube furnace, heat it up to 700°C at 3°C / min under the protection of helium, and carbonize it at a constant temperature for 1h; after natural cooling, add the product to 0.2mol L -1 The HCl solution was stirred for 10 min to remove impurity ions K + and Na + ; and then washed with distilled water and ethanol to pH = 7, and dried to obtain a nitrogen-doped porous carbon material.

Embodiment 2

[0034] S1. Weigh 4 parts by weight of tripotassium EDTA and 1 part by weight of sodium chloroacetate;

[0035] S2, the two are ground in a mortar for 15 minutes;

[0036] S3. Put it in a tube furnace, heat it up to 500°C at 3°C / min under the protection of helium, and carbonize it at a constant temperature for 1h; after cooling, add the product to 0.2mol L -1 The HCl solution was stirred for 10 min to remove impurity ions K + and Na + ; and then washed with distilled water and ethanol to pH = 7, and dried to obtain a nitrogen-doped porous carbon material.

Embodiment 3

[0038] S1. Weigh 4 parts by weight of tripotassium EDTA and 1 part by weight of sodium chloroacetate;

[0039] S2, the two are ground in a mortar for 15 minutes;

[0040] S3, it is placed in the tube furnace, in N 2 Under protection, the temperature was raised to 600 °C at 3 °C / min, and then carbonized at a constant temperature for 1 h; after cooling, the product was added to 0.2 mol L -1 The HCl solution was stirred for 10 min to remove impurity ions K + and Na + ; and then washed with distilled water and ethanol to pH = 7, and dried to obtain a nitrogen-doped porous carbon material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap