Method for Preparing Carbon Nanotube Fiber And Carbon Nanotube Fiber Prepared Thereby

a carbon nanotube fiber and carbon nanotube fiber technology, which is applied in the field of preparation of carbon nanotube fiber and carbon nanotube fiber thereby, can solve the problems of difficult to sufficiently express excellent properties of carbon nanotubes, difficult to disperse carbon nanotubes at a high concentration and maintain dispersibility, etc., and achieve the effect of enhancing the tensile strength of the carbon nanotube fiber, the final product, and increasing the binding force between carbon nanotubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0038]Hereinafter, examples of the present invention will be described in detail so as to be easily carried out by those of ordinary skill in the art to which the present invention pertains. However, the present invention may be implemented in a variety of different forms, and is not limited to the examples which will be described herein.

examples 1 to 6

, and Comparative Examples 1 to 3

Preparation of Carbon Nanotube Fiber

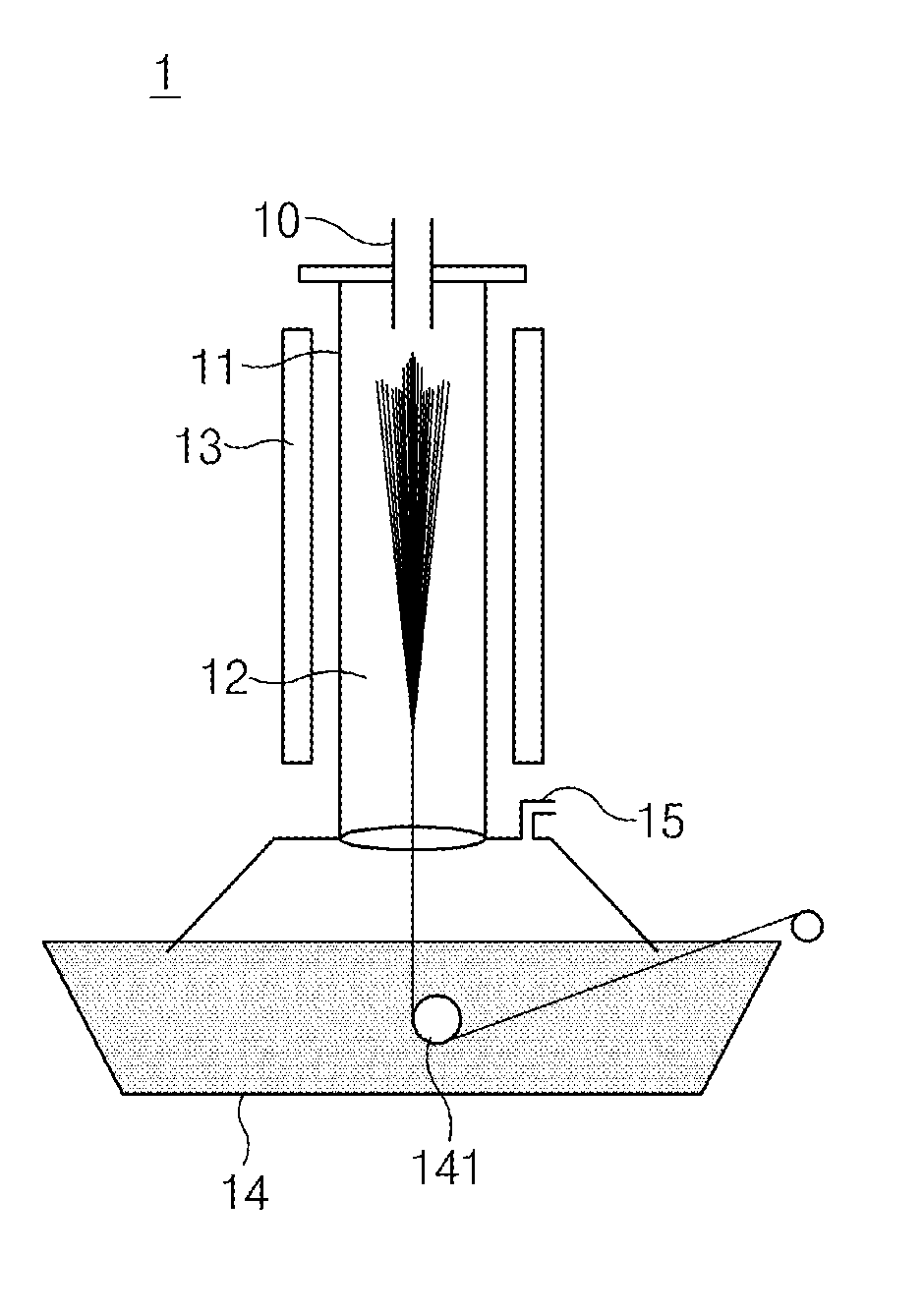

[0039]A carbon nanotube fiber was prepared by the following method using an apparatus for preparing a carbon nanotube fiber, which includes a reactor main body including a reaction zone; an inlet which is located at an upper portion of the main body, and allows the flow of a carbon source and a carrier gas into the reaction zone; a heating means which serves to heat the reaction zone; and a water vessel equipped at a lower portion of the main body to discharge a carbon nanotube fiber to the outside of the apparatus.

[0040]A temperature in the reaction zone was elevated to 1,200° C. under a nitrogen atmosphere. Fe(C5H5)2 as a catalyst precursor and sulfur (S) as a catalytic activator were put into the reaction zone adjacent to the inlet. Fe(C5H5)2 and the catalytic activator S were added by vaporization at average rates of 0.07 g / hr and 0.02 g / hr, respectively, and synthesis was performed for 3 hours by feeding meth

experimental example 1

Evaluation of Characteristics of Carbon Nanotube Fiber and Carbon Nanotube Fiber Composite

[0044]The tensile strengths of carbon nanotube fibers of Examples 1 to 6 and

[0045]Comparative Examples 1 to 3 and a carbon nanotube fiber composite of Comparative Example 4 were measured using FAVIMAT+ (Manufacturer: TEXTECHNO). The linear density of the fibers was measured according to ASTM D1577, and after a fiber tensile test, the breaking strength of a fiber was divided by the linear density, thereby measuring the tensile strength. Detailed measurement conditions are as follows. Based on Comparative Example 1, the tensile strengths were evaluated as relative values with respect to Comparative Example 1, and the values are shown in Table 2 below.

[0046]Measurement conditions: a load cell of 210 cN, a Gauge length of 2 cm, and a speed of 2 mm / min

TABLE 2DivisionTensile strengthExample 1118.3Example 2133.6Example 3138.9Example 4167.9Example 5129.0Example 6126.0Comparative100.0Example 1Comparative

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap