Lithium iron phosphate/carbon nanobelt composite material, preparation method and lithium ion battery

A technology of carbon nanobelt and lithium iron phosphate, which is applied in the direction of nanocarbon, nanotechnology, phosphorus compounds, etc., can solve the problems of poor conductivity and achieve the effects of improving conductivity, improving diffusion kinetics, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

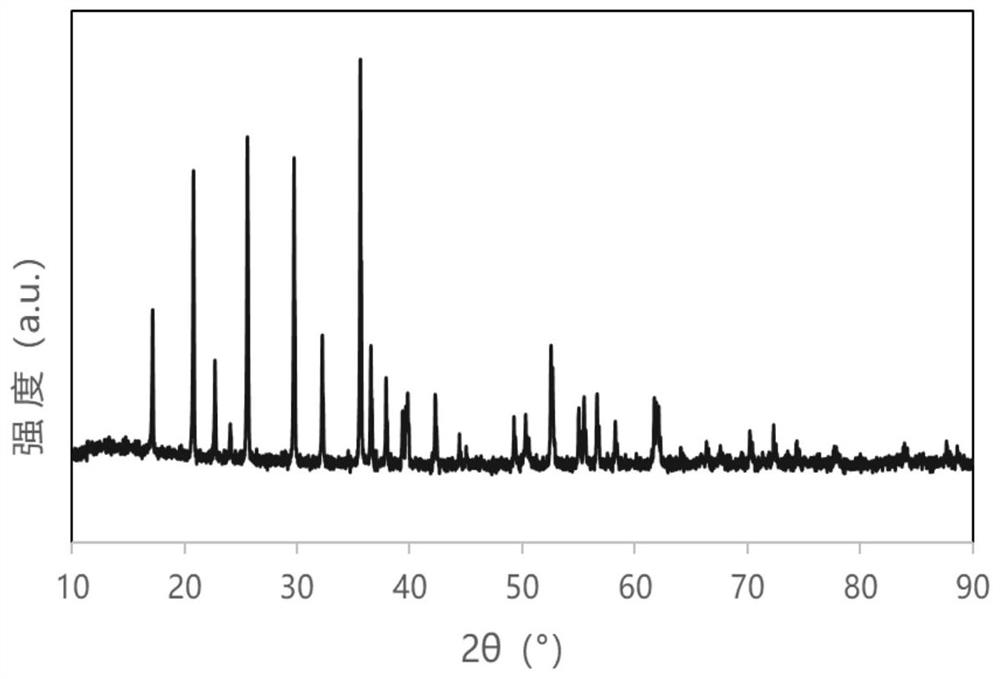

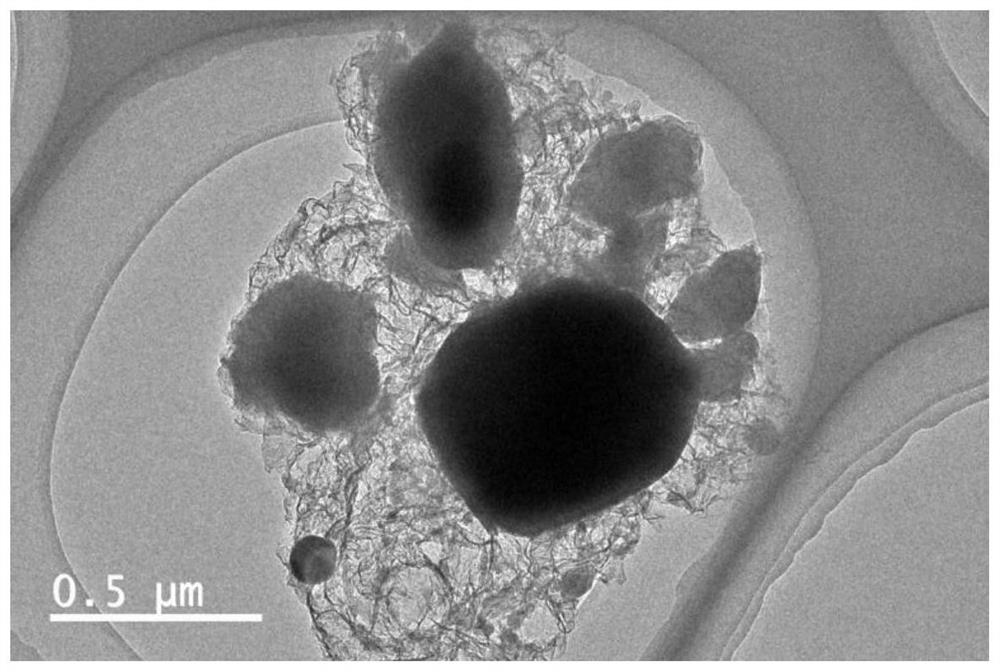

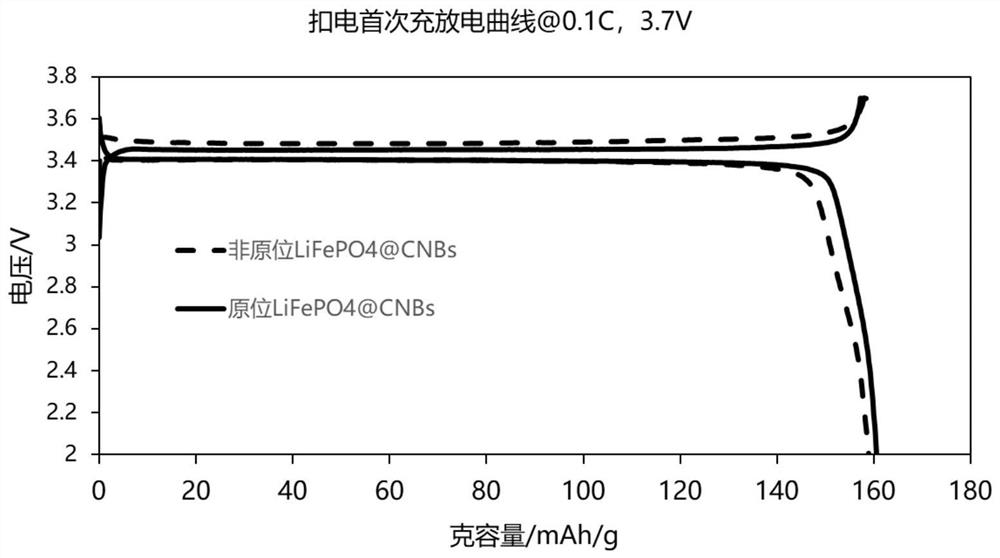

[0024] As described in the background art, there is a problem of poor electrical conductivity when using the existing in-situ carbon coating method to prepare carbon-coated lithium iron phosphate materials. In order to solve the above technical problems, the application provides a preparation method of lithium iron phosphate / carbon nanobelt composite material, the preparation method of lithium iron phosphate / carbon nanobelt composite material comprises: making carbon source compound, lithium source compound, iron source The compound, the sodium source compound and the phosphorus source compound are subjected to hydrothermal synthesis reaction to obtain a precursor, wherein the sodium source compound is selected from one or more of the group consisting of sodium chloride, sodium sulfide and sodium fluoride; under an inert atmosphere , the precursor is calcined to obtain the lithium iron phosphate / carbon nanobelt composite material.

[0025] In the hydrothermal synthesis reac

Embodiment 1

[0041] A preparation method of lithium iron phosphate / carbon nanobelt composite material, comprising:

[0042] Step 1: Weigh 0.94g of melamine and add it to 50mL of dimethyl sulfoxide solution, ultrasonically disperse it to make it fully dissolved, then add 1.5g of hydroquinone to obtain mixed solution A.

[0043] Step 2: Add phosphoric acid, ferrous chloride, lithium carbonate, and sodium fluoride with a stoichiometric ratio (ratio of moles) of 1:1:1:0.01 to solution A obtained in step 1, add 100mL of aqueous solution, and stir well , to obtain mixed solution B. Among them, the total weight m of lithium source compound, iron source compound, sodium source compound and phosphorus source compound 1 , and the total weight of the synthesized carbon source compound m 2 The ratio of 90:10, pH=9.

[0044] Step 3: Transfer the solution B obtained in step 2 to a high-pressure reactor, and then place it in an oven at 180°C for 6 hours. After the reaction is completed and cool to room

Embodiment 2

[0048] A preparation method of lithium iron phosphate / carbon nanobelt composite material, comprising:

[0049] Step 1: Weigh 0.47g of melamine and add it to 50mL of dimethyl sulfoxide solution, ultrasonically disperse it to make it fully dissolved, then add 0.75g of hydroquinone to obtain mixed solution A.

[0050] Step 2: Add phosphoric acid, ferrous chloride, lithium carbonate, and sodium chloride with a stoichiometric ratio (ratio of moles) of 1:1:1:0.05 to solution A obtained in step 1, add 100mL of aqueous solution, and stir well , to obtain mixed solution B. Among them, the total weight m of lithium source compound, iron source compound, sodium source compound and phosphorus source compound 1 , and the total weight of the synthesized carbon source compound m 2 The ratio of 90:10, pH=9.

[0051] Step 3: Transfer the solution B obtained in step 2 to a high-pressure reactor, and then place it in an oven at 180°C for 6 hours. After the reaction is completed and cool to roo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap