Efficient and energy-saving diamond saw blade and tungsten steel saw blade

A diamond saw blade, high-efficiency and energy-saving technology, used in stone processing tools, stone processing equipment, fine working devices, etc. The problem of short service life and high production cost can achieve the effect of promoting effective utilization, improving production efficiency and small friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

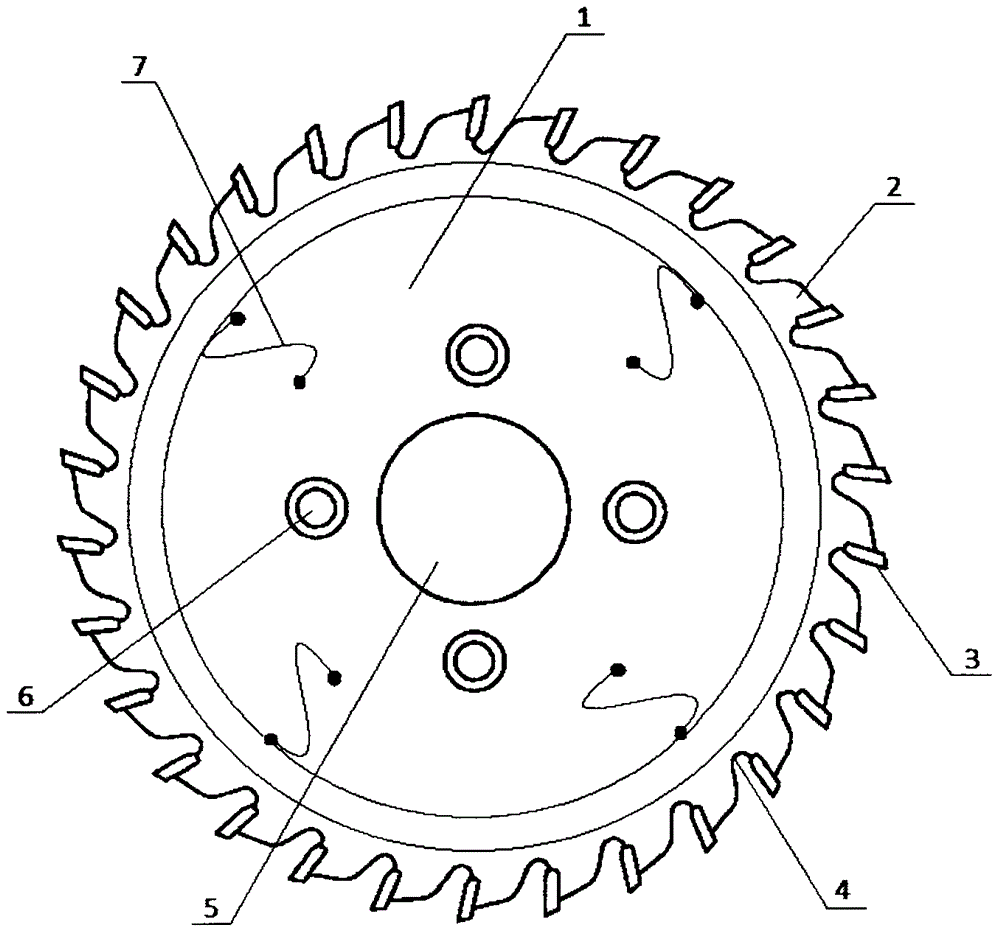

[0012] In order to overcome the defects existing in the existing high-hardness material cutting device and meet the actual needs, a high-efficiency and energy-saving diamond saw blade and tungsten steel saw blade (such as figure 1 , figure 2 ), including the saw blade body 1, the center of the saw blade body 1 is provided with a mounting hole 5, the saw blade body 1 is a metal plate on the horizontal plane of the disc, and the edge of the saw blade body 1 is evenly provided with several sawtooth fixing seats 2 of the same shape and size. There is an inclined U-shaped chip removal groove 4 between two adjacent sawtooth fixing seats 2. The sawtooth 3 with granular diamond or tungsten steel material whose end is higher than the sawtooth fixing seat 2 is connected, and the sawtooth 3 and the groove on the front side of the sawtooth fixing seat 2 are fixedly connected by bonding or welding; the sawtooth 3 The thickness of the saw blade body 1 is larger than that of the saw blade bod

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap