Semiconductor radiator and processing method thereof

A processing method and radiator technology, applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of high radiator processing temperature, low radiator production efficiency, small radiator column heat dissipation area, etc., and achieve processing efficiency Improvement, reduction of raw material consumption, high hardening strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

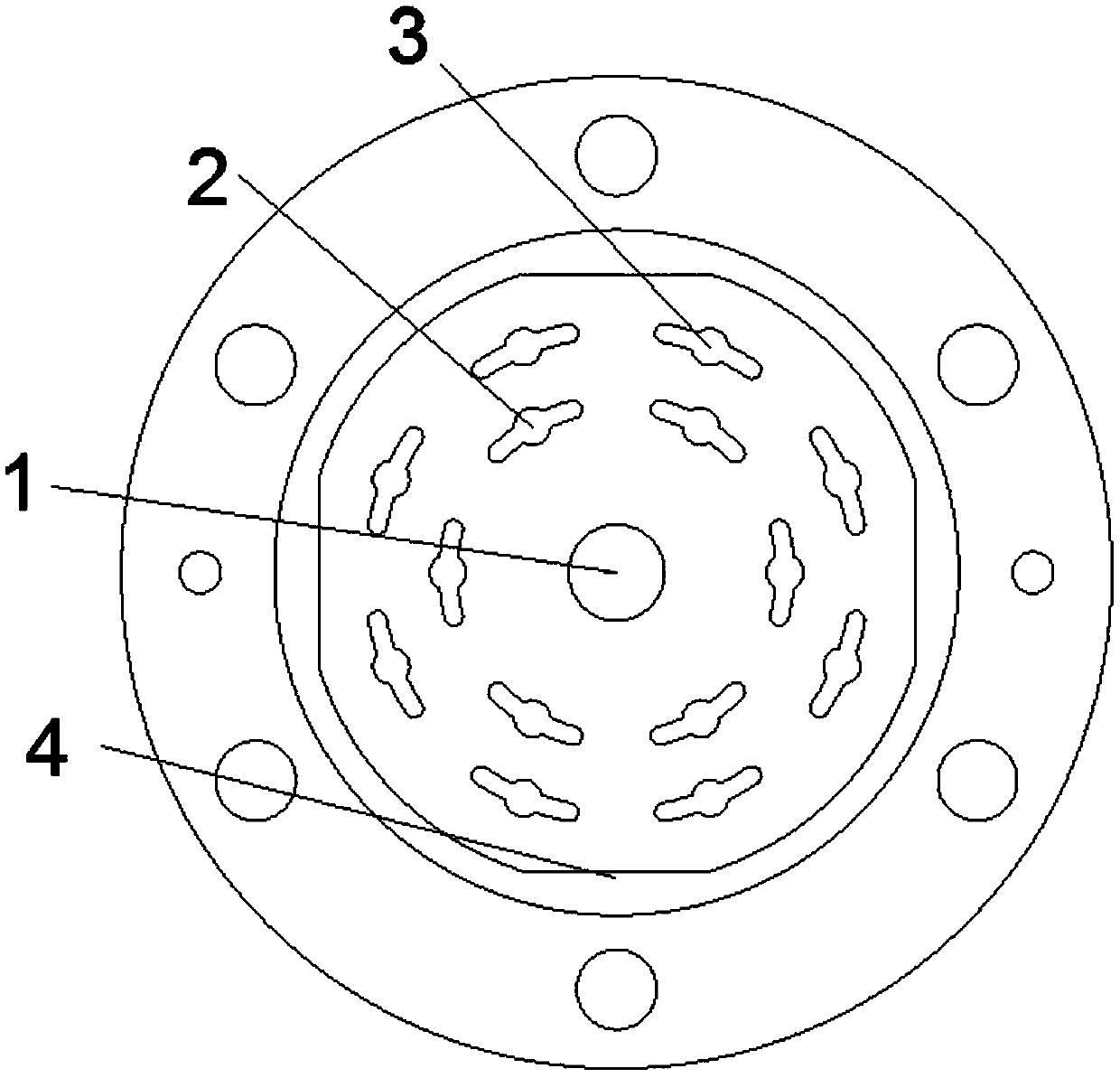

Image

Examples

Embodiment 1

[0044] Select T2 pure copper with a diameter of 49mm as the raw material, cut the T2 pure copper into a cylindrical blank with a thickness of 40mm with a sawing machine; anneal the cylindrical blank in a well-type vacuum annealing furnace at 500°C; then roll it with T200 swing machine for one pre-forming, and the T200 oscillating rolling machine has a work rate of 8.4mm / s; then use the well-type vacuum annealing furnace for the second annealing treatment; then put the workpiece into the lower part of the T630 oscillating rolling machine In the mold, the upper mold adopts a circular track for swing forming, the holding time is 1s, and the pressure is 40% of the total pressure, and then a turning is carried out by the workshop, and finally the semiconductor radiator is obtained.

Embodiment 2

[0046] Select T2 pure copper with a diameter of 49mm as the raw material, cut the T2 pure copper into a cylindrical blank with a thickness of 50mm with a sawing machine; anneal the cylindrical blank in a well-type vacuum annealing furnace at 600°C; then use T200 swing rolling machine for one pre-forming, and the work rate of T200 oscillating rolling machine is 10mm / s; then use the well-type vacuum annealing furnace for the second annealing treatment; then put the workpiece into the lower mold of T630 oscillating rolling machine In the middle, the upper mold adopts a circular track for rotary rolling, the holding time is 1.2s, and the pressure is 50% of the total pressure, and then a turning is carried out by the workshop, and finally the semiconductor radiator is obtained.

Embodiment 3

[0048] Select T2 pure copper with a diameter of 49mm as the raw material, cut the T2 pure copper into a cylindrical blank with a thickness of 60mm with a sawing machine; anneal the cylindrical blank in a well-type vacuum annealing furnace at 700°C; then use T200 swing rolling machine for one pre-forming, and the T200 oscillating rolling machine has a work rate of 20mm / s; then use the well-type vacuum annealing furnace for the second annealing treatment; then put the workpiece into the lower mold of the T630 oscillating rolling machine In the middle, the upper mold adopts a circular trajectory for rotary rolling, the holding time is 3s, and the pressure is 60% of the total pressure, and then a turning is carried out by the workshop, and finally the semiconductor radiator is obtained.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap