Steel ball mounting machine with bearing holding frame

A technology of bearing cage and cage, which is applied in the field of bearing assembly, can solve problems such as low production efficiency, unsatisfactory efficiency, and high labor intensity, and achieve the effects of high production efficiency, simple and reasonable structure, and light labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions in the embodiments of the present invention will be clearly and completely described below. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

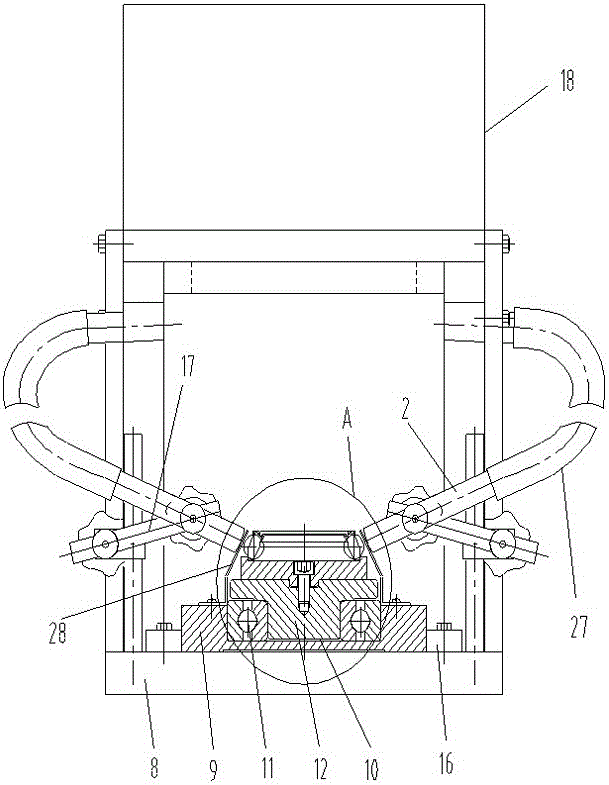

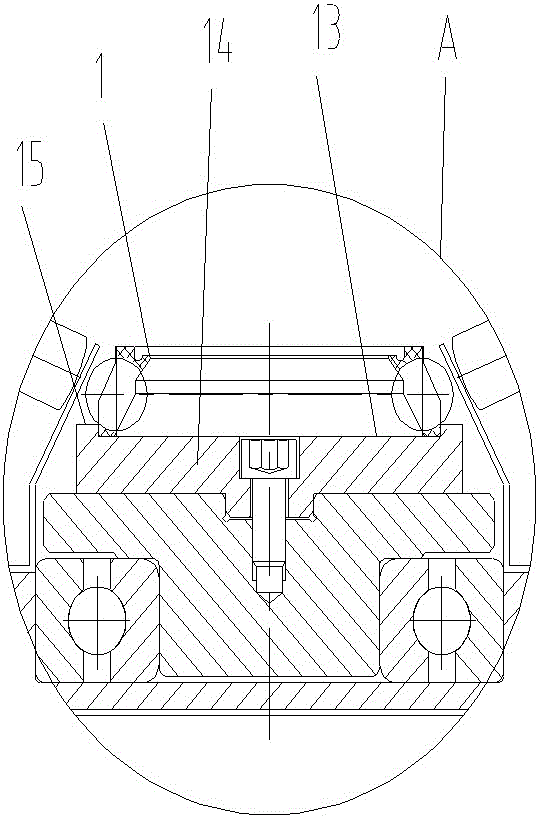

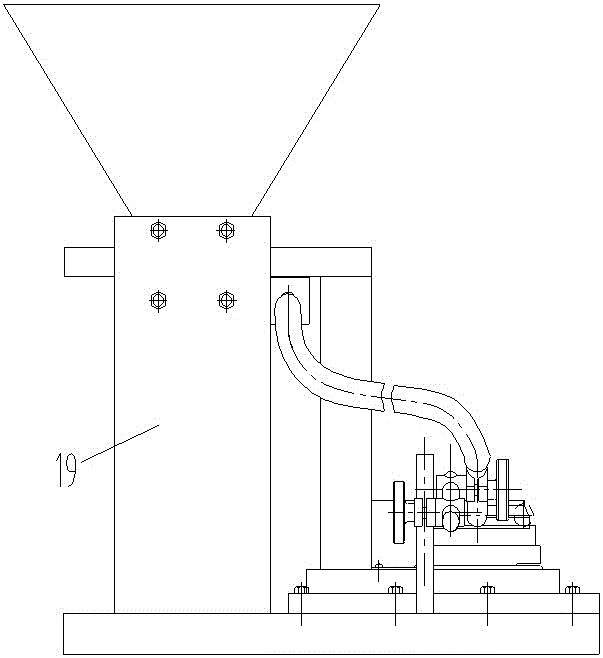

[0032] see Figure 1 to Figure 9 , the embodiments of the present invention include:

[0033] like Figure 1 to Figure 8 As shown, a bearing cage steel ball installation machine includes: a cage rotation device, at least one guide ball hard tube and a steel ball supply device.

[0034] The cage rotating device is used to carry the cage 1 and drive the cage to rotate. Specifically, the holder rotating device includes a base 8, a carriage 9 is placed above the base, a groove 10 is formed in the middle of the carriage, and

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap