Drum-gear angular flexible coupling

A technology of flexible couplings and gear couplings, which is applied in the direction of elastic couplings, couplings, bearing components, etc., can solve the problems of accelerated wear, high power transmission, and reduced service life of gear couplings. Achieve the effect of reducing the starting current power, increasing the service life of drum teeth, and transmitting large torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The drum gear angular flexible coupling of the present invention will be further described in detail below in conjunction with the accompanying drawings.

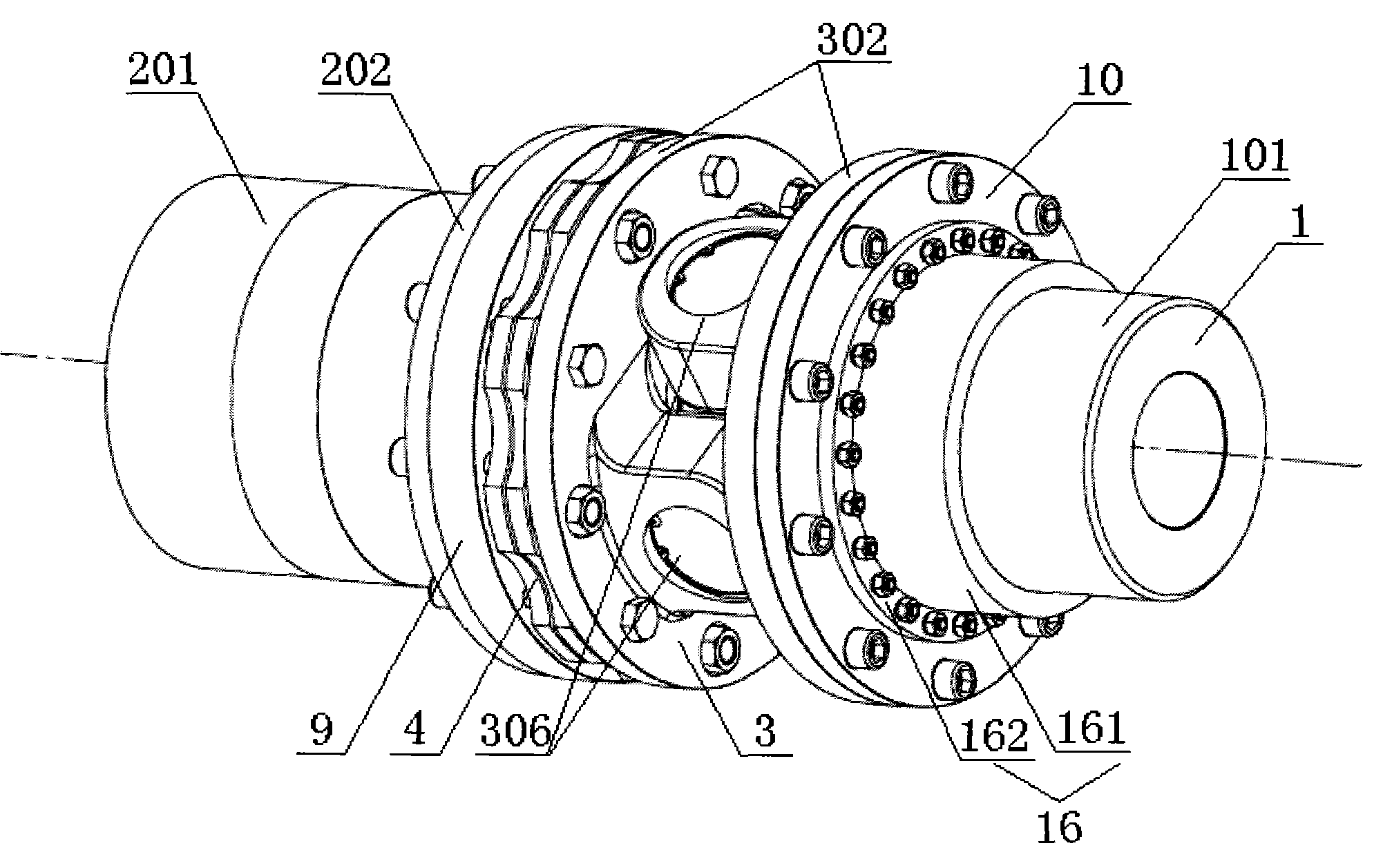

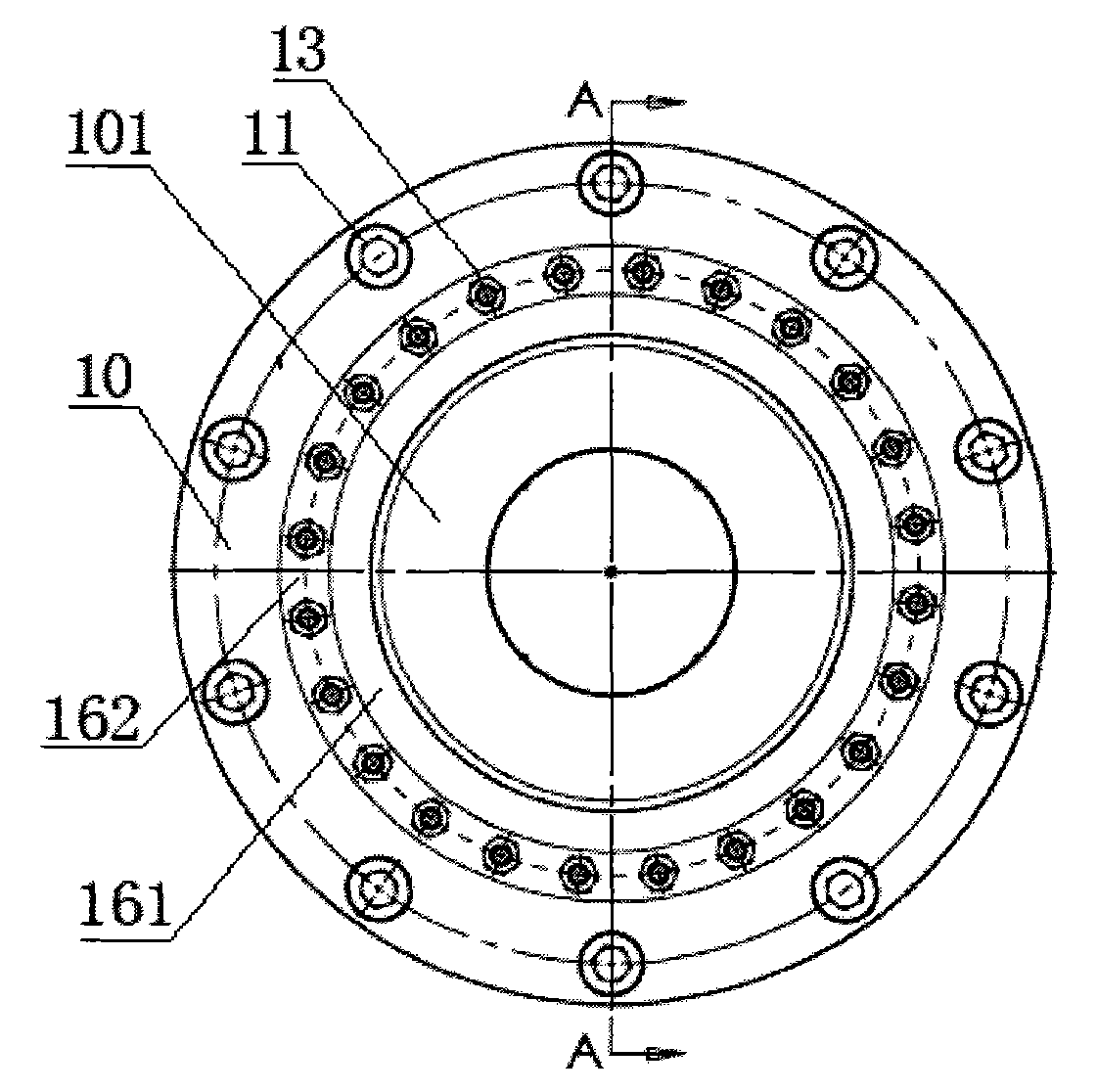

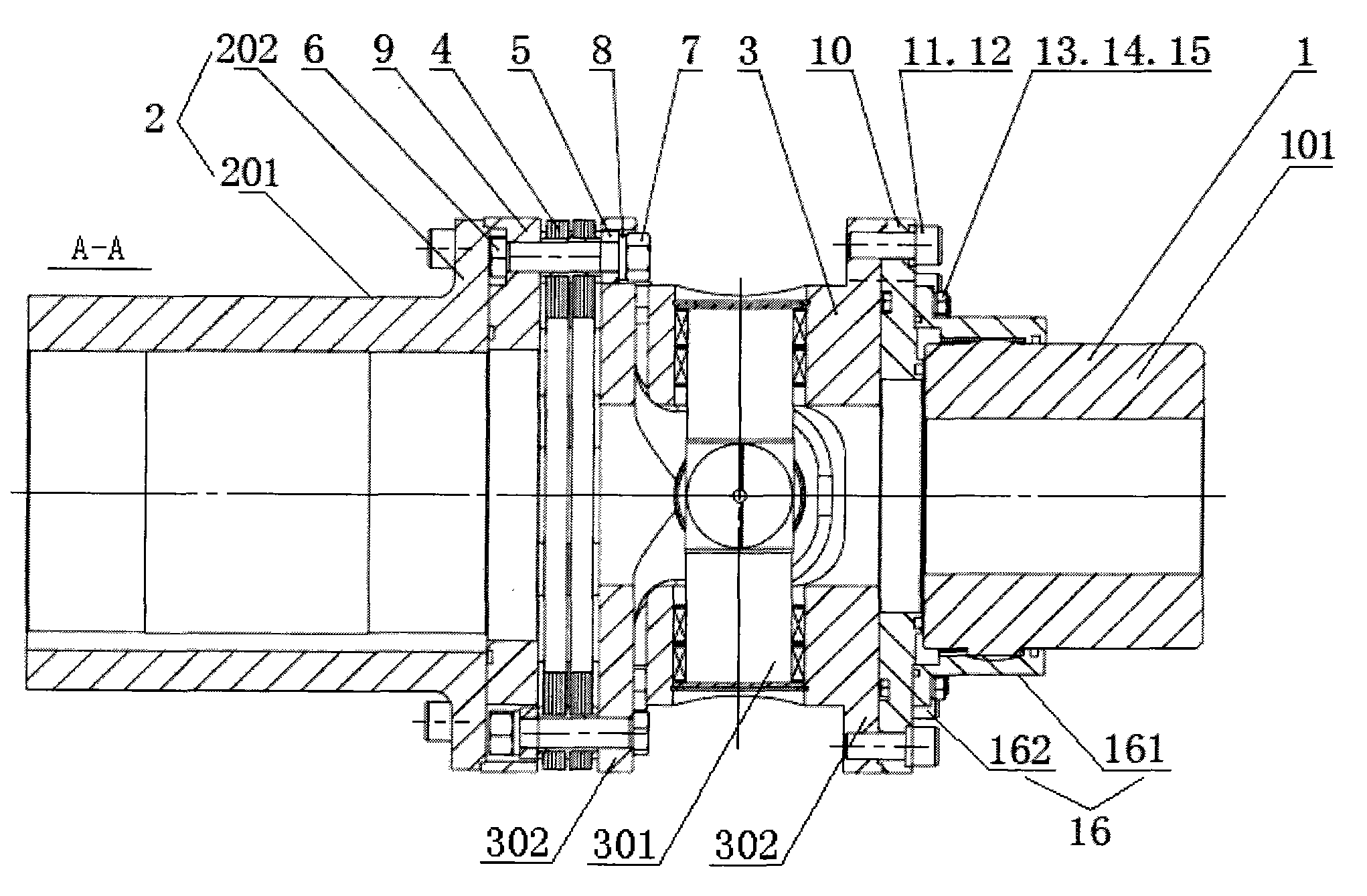

[0025] Such as Figure 1-4 As shown, the coupling of the present invention includes a driven machine end half coupling 1, a driving machine end half coupling 2, an angler 3, a diaphragm group 4, a drum gear coupling half coupling 16 and two a docking plate. The left side of the angler 3 is sequentially connected with the diaphragm group 4, the docking disc I9 and the half-coupling 2 of the main machine end from the inside to the outside, and the right side of the angler 3 is connected with the docking disc II10 and the drum tooth in sequence from the inside to the outside. Coupling half-coupling 16 and driven machine end half-coupling 1.

[0026] Such as Figure 4 As shown, the angler 3 includes a cross shaft 301 and two connection plates 302, the cross shaft 301 includes a grease nozzle 303 and four hollow shafts 30

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap