Vacuum oil injection device and method for oil bearing

An oil injection device and bearing technology, which is applied to shafts and bearings, bearing components, and lubricating oil input, can solve the problem of less oil injection in oily bearings, and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

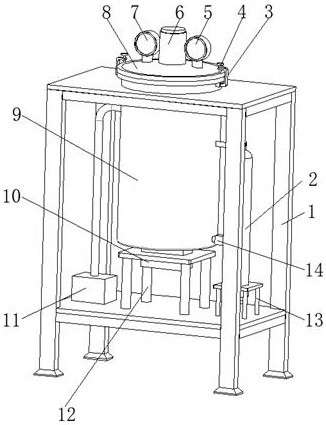

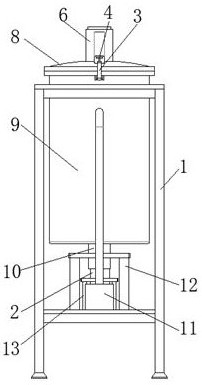

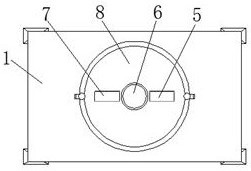

[0039] Such as Figure 1-6 As shown, the embodiment of the present invention provides a vacuum oiling device for oil-impregnated bearings, including a frame 1, the frame 1 is made of stainless steel as a whole, anti-skid feet are installed on the bottom of the frame 1, and the horizontal part of the upper part of the frame 1 is set There is a tank body 9, the lower inner wall of the tank body 9 is provided with an electric heating device 15, after adding lubricating oil in the tank body 9, the lubricating oil can be heated by the electric heating device 15, and the upper top surface of the tank body 9 is provided with an upper cover 8 , the inner side of the upper top surface of the tank body 9 is provided with a sealing ring 19, which can ensure the tightness of the upper cover 8 and the tank body 9 after being compressed by the pressing button 4 and vacuumized by the vacuum pumping device 11 through the sealing ring 19 , the upper top surface of loam cake 8 is provided with the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap