Electric corrosion preventing bearing

A technology for anti-electric corrosion and bearings, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of reduced service life of bearings, increased heat generation, and restrictions on the use of bearings, achieving increased service life, simple structure, good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

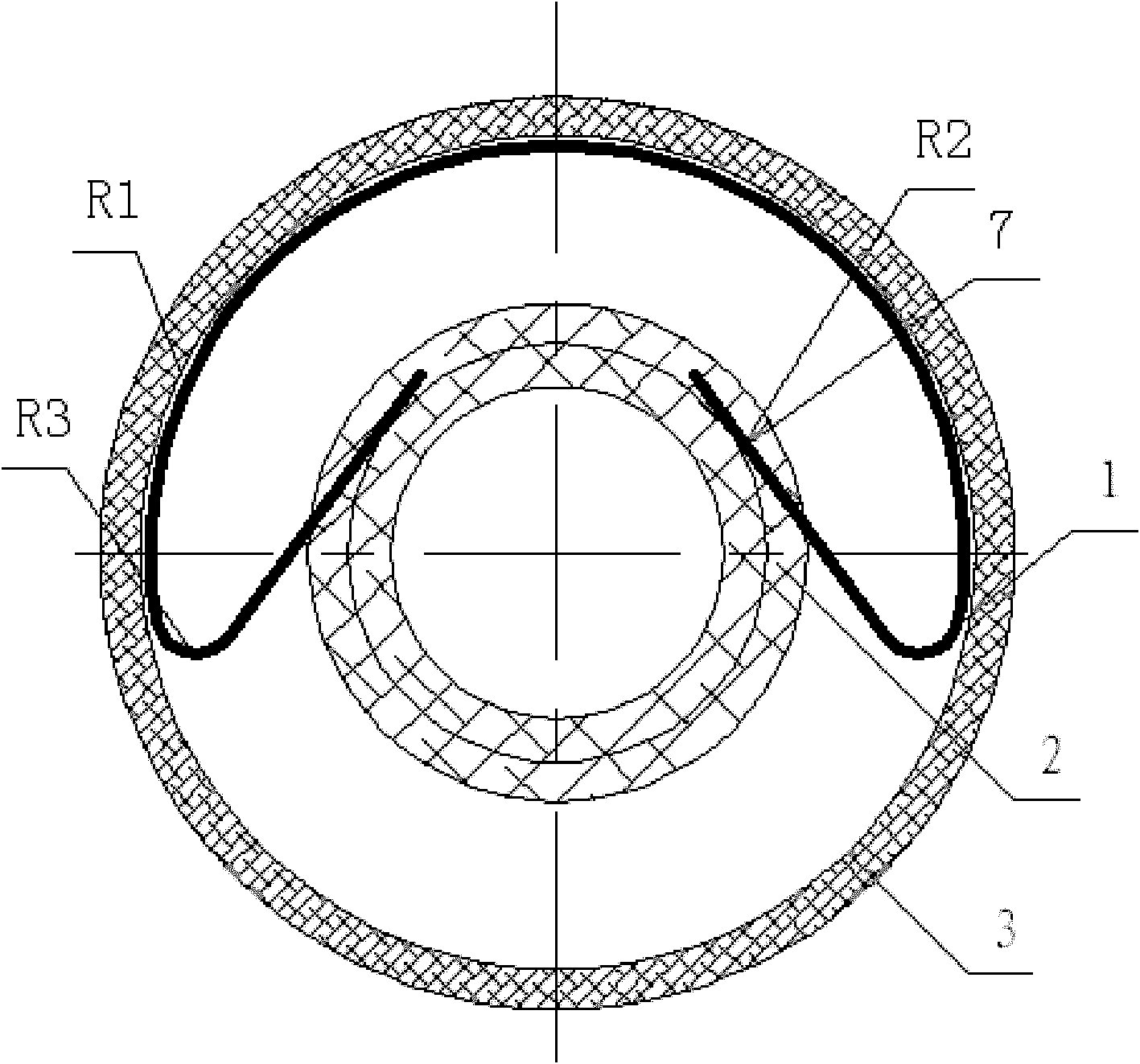

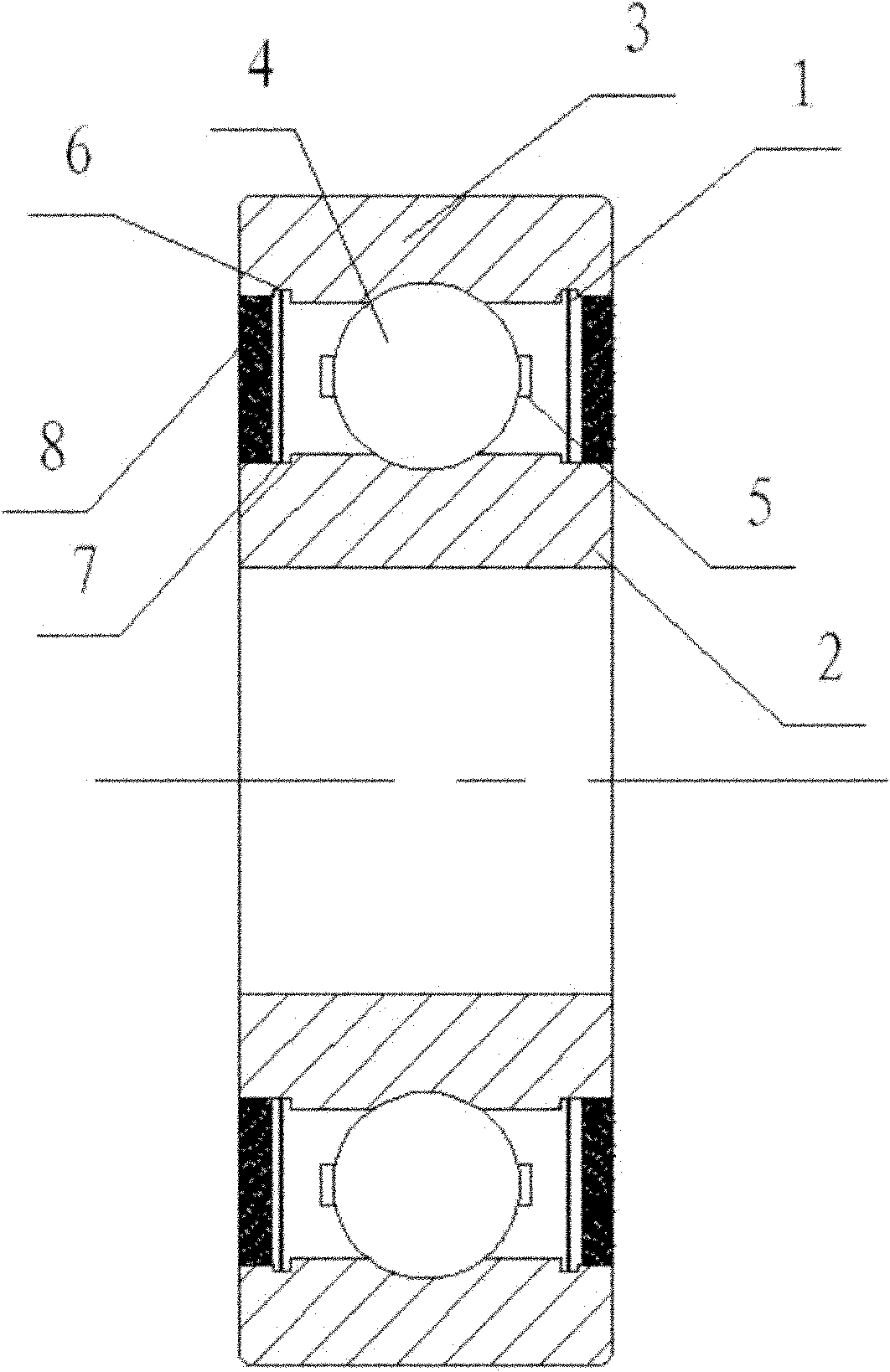

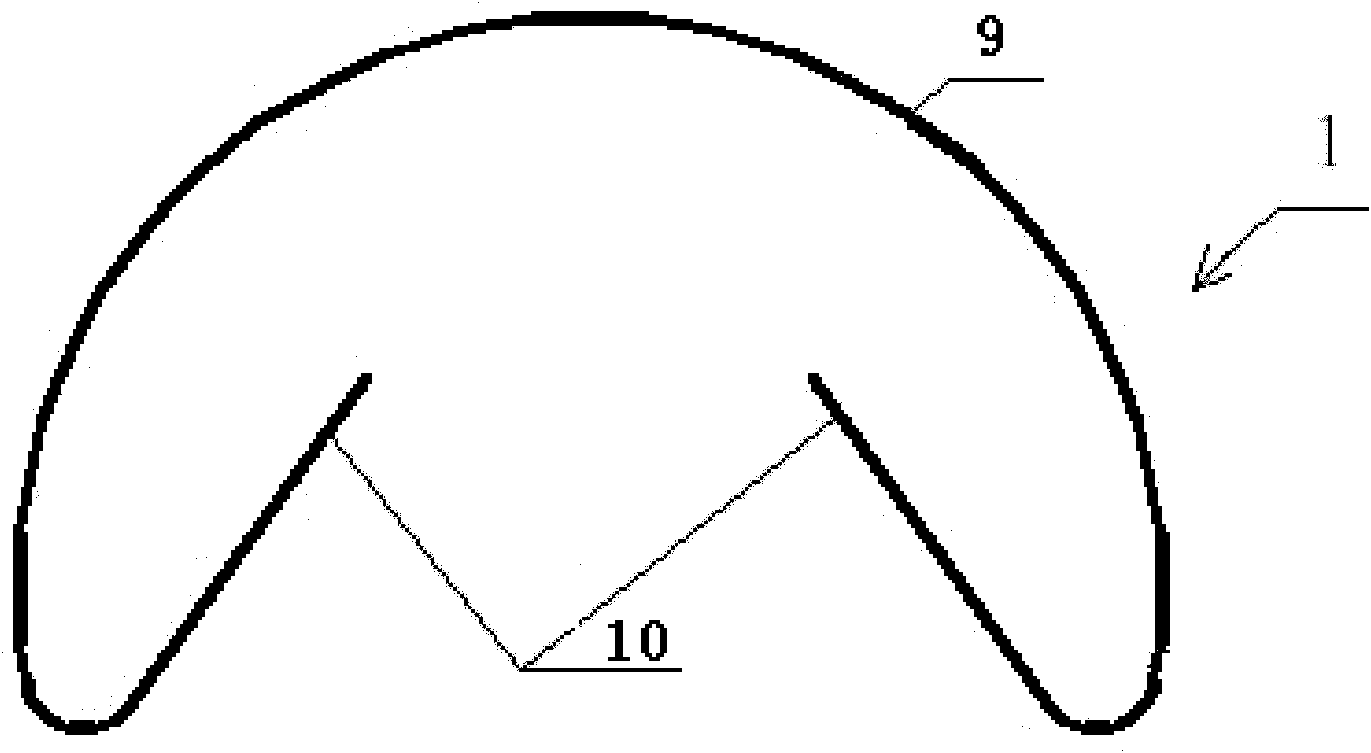

[0019] The present invention includes an inner ring 2, an outer ring 3, and a rolling body 4 located between the inner ring 2 and the outer ring 3. A conductive elastic ring 1 is arranged between the outer ring 3 and the inner ring 2, and the elastic ring 1 and Outer ring 3 and inner ring 2 are in contact. The elastic ring 1 includes an arc edge 9 matched with the outer ring 3 and two straight edges 10 bent inwardly connected to both ends of the arc edge 9 , and the two straight edges 10 are in contact with the inner ring 2 . The arc length of the arc edge 9 of the elastic ring 1 is 1 / 2-2 / 3 of the circumference length of the inner hole of the outer ring 3 . The left and right ends of the inner ring 2 are respectively provided with inner ring seams 7 higher than the outer end, and the left and right ends of the inner hole wall of th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap