Sealing system

a sealing system and sealing technology, applied in mechanical equipment, piston rings, transportation and packaging, etc., can solve the problems of reducing the effectiveness of sealing, affecting the lubrication of the bushing, and affecting so as to facilitate the lubrication effect of the bushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Reference will now be made in detail to exemplary embodiments that are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

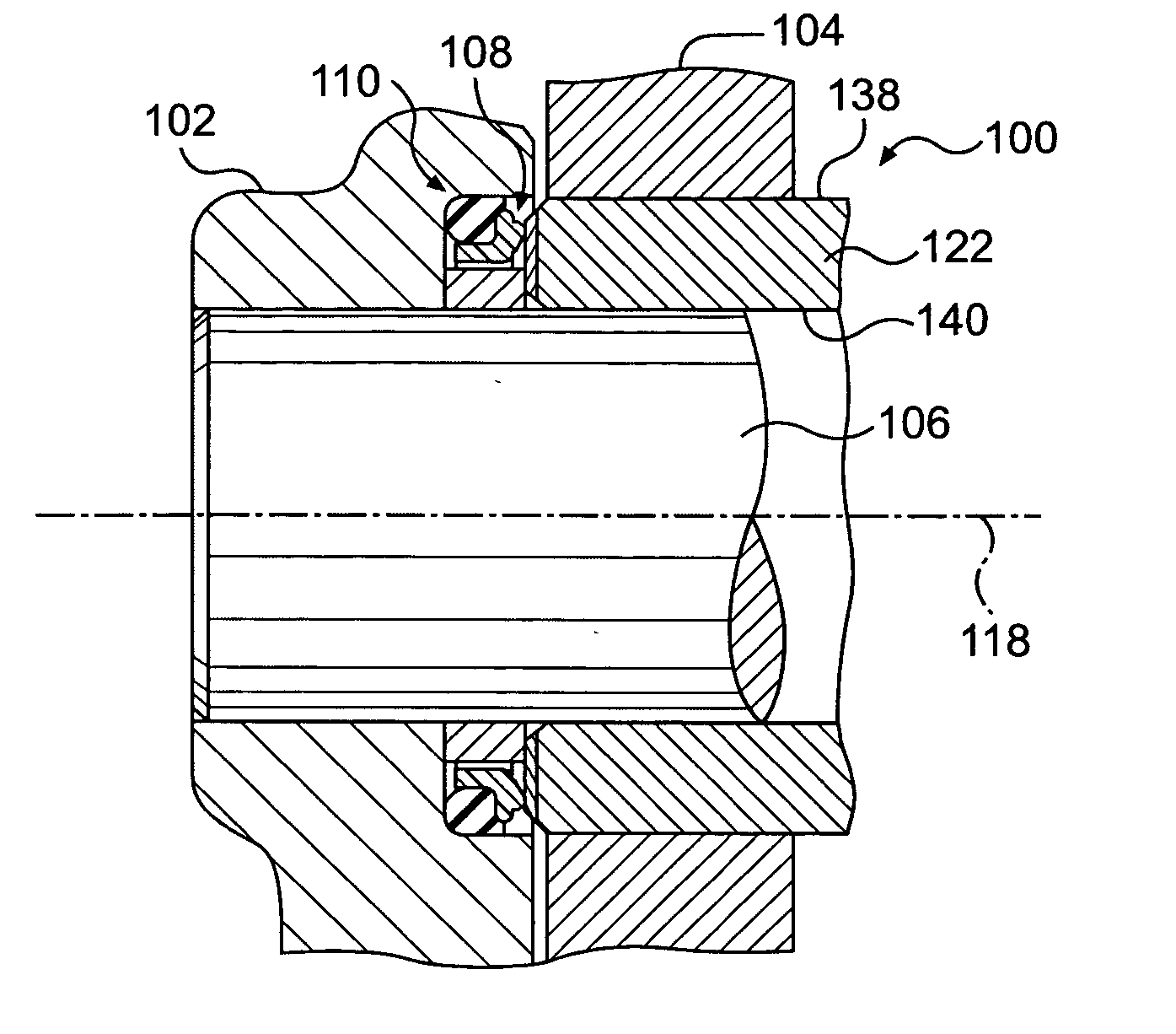

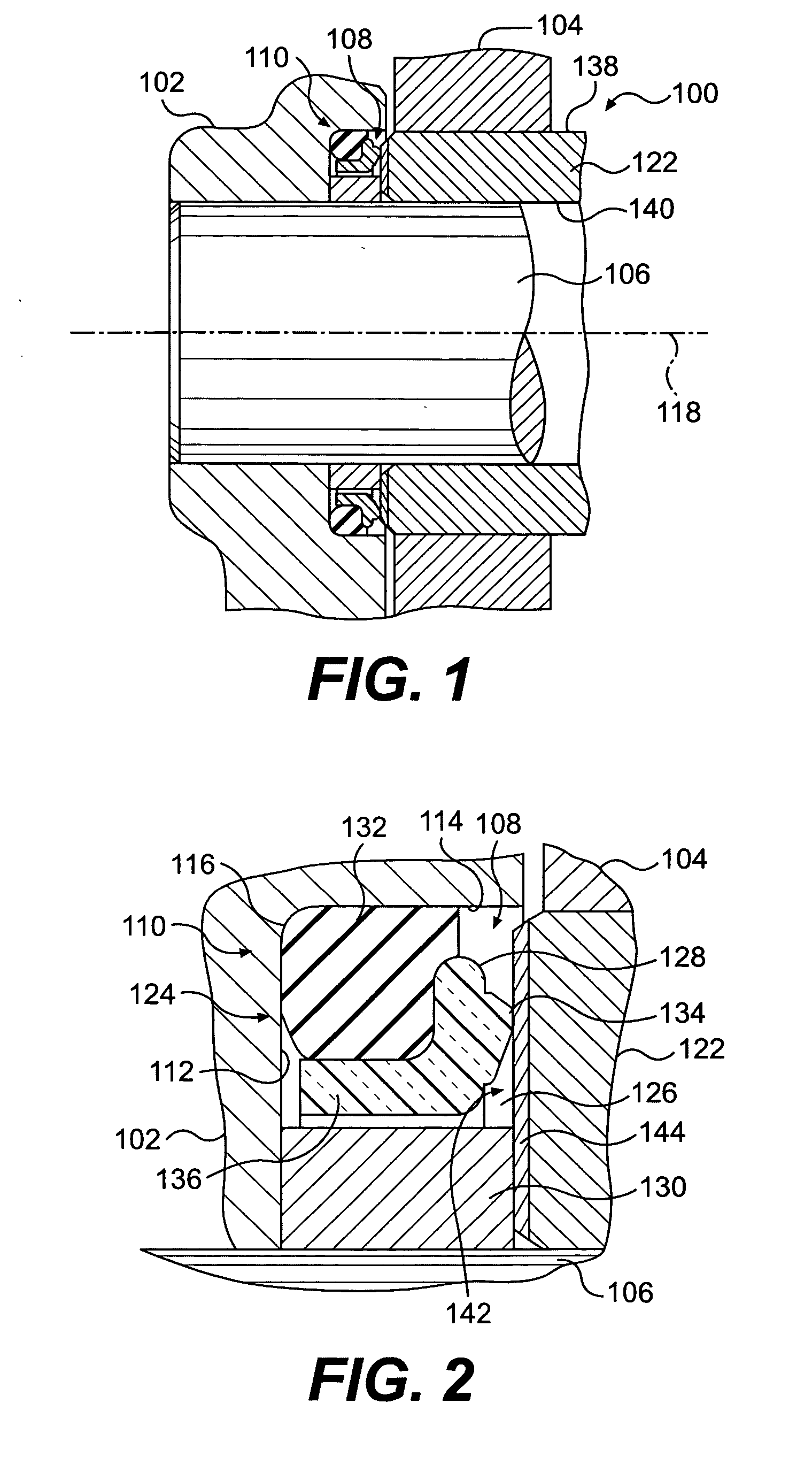

[0013]FIG. 1 shows an exemplary embodiment of one end of a track joint 100 of an endless track for a track-type work machine. The track joint 100 includes first and second pivotally interconnected overlapping links 102, 104, a track pin 106, and a sealing system 108. The links 102, 104 extend from the track joint 100 and connect to adjacent track joints (not shown) to create a track for a track-type work machine.

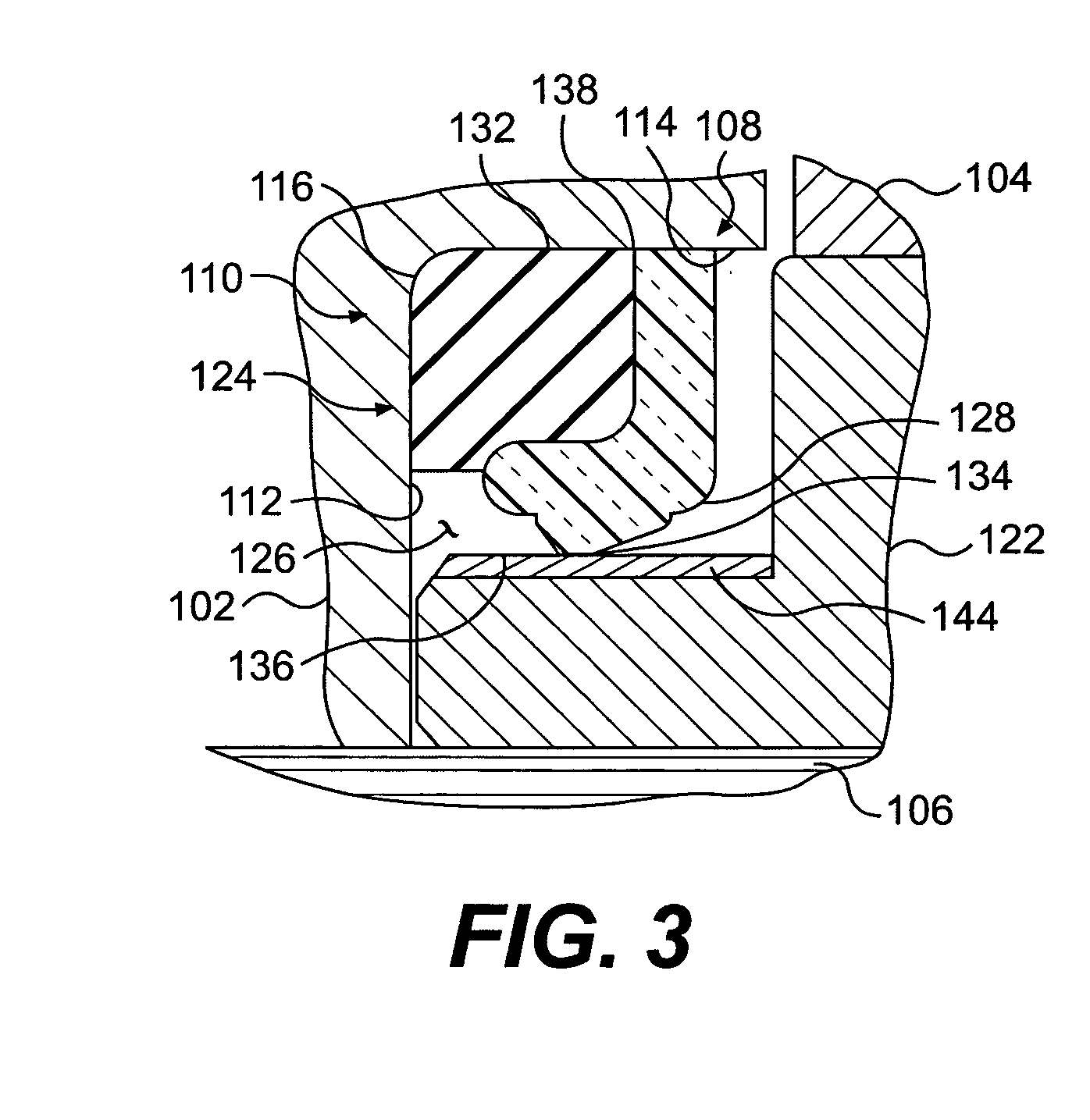

[0014]FIG. 2 is an enlargement of the track joint 100 shown in FIG. 1. As best seen in FIG. 2, the first link 102 includes a counter-bore 110 that is defined by an axially outwardly facing bore face 112, a cylindrical surface 114, and a corner portion 116.

[0015] The sealing system 108 is disposed intermediate the links 102, 104 and may be co

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap