Automobile suspension bushing and suspension

A technology of automobile suspension and bushing, which is applied in the direction of suspension, vehicle parts, cantilever installed on the pivot, etc., and can solve the problems of driver's discomfort, suspension bush pivot pin and outer cylinder pull-off separation, etc. , to achieve the effect of good economy, meeting the requirements of stiffness and comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

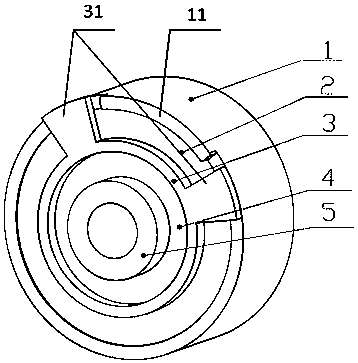

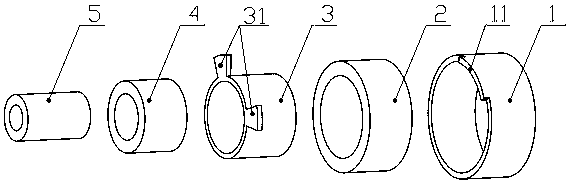

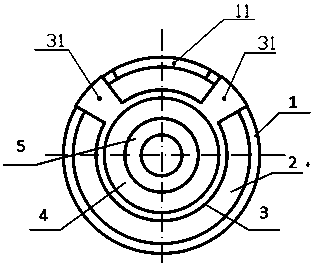

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings of the present invention. . It should be noted that the drawings are only used to explain the patent of the present invention, and are schematic descriptions of the embodiments of the present invention, but should not be construed as limiting the present invention. The words "inner" and "outer" are used in the following description to refer to directions toward or away from the geometric center of a particular component, respectively.

[0018] see figure 1 with figure 2 , the automotive bushing provided in this embodiment is composed of five parts: an outer tube 1, an outer rubber body 2, an adjustment tube 3, an inner rubber body 4, and an inner tube 5. The rubber body 2, the inner rubber body 4 vulcanized and fixed between the inner diameter of the regulating pipe 3 and the outer diameter of the inner pipe

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap