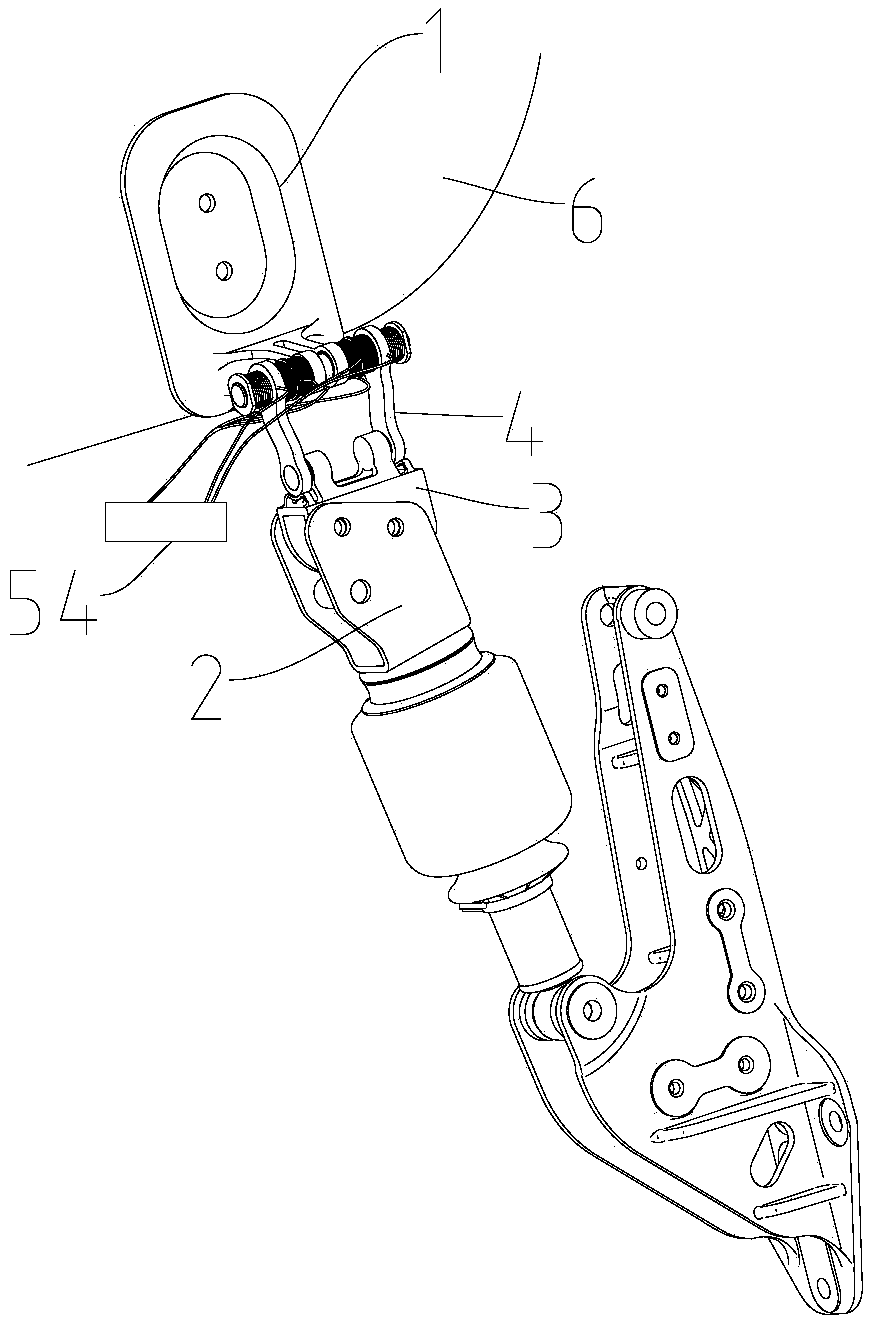

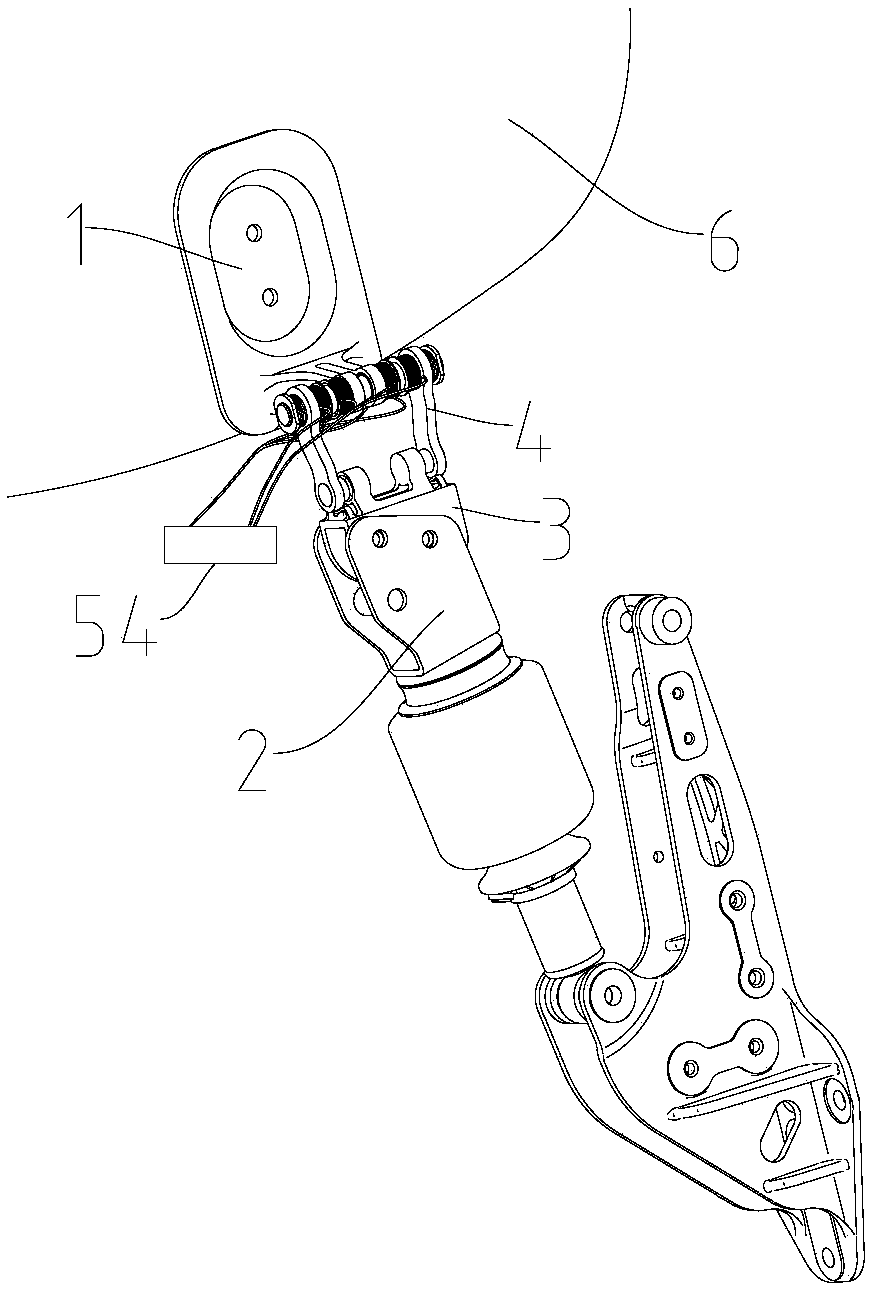

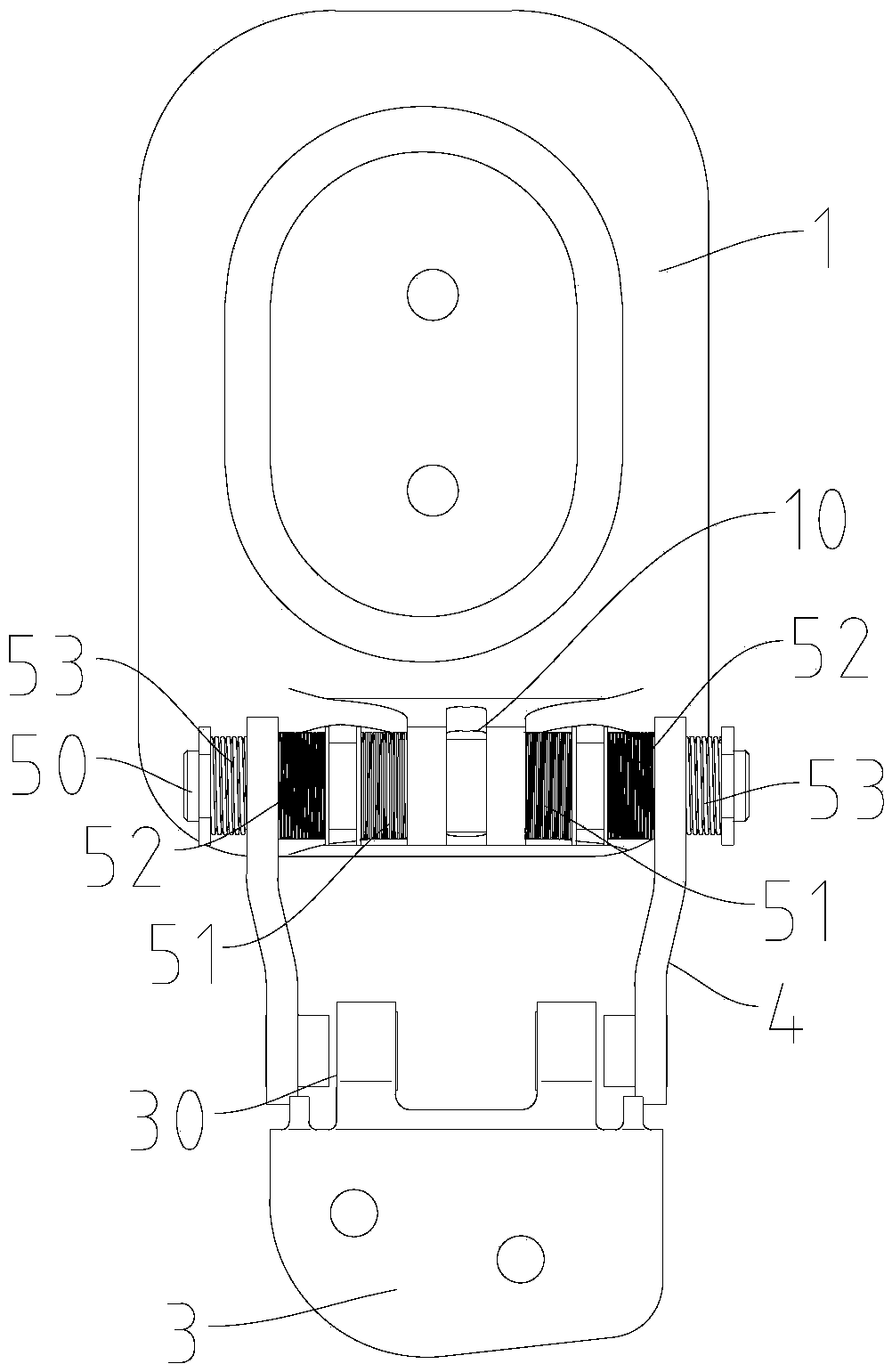

Locking mechanism, cab rear suspension locking mechanism and vehicle

A locking mechanism and cab technology, applied in vehicle parts, superstructure, transportation and packaging, etc., can solve the problems of hydraulic lock oil pipe joint breakage, complicated unlocking operation process, hydraulic lock unlocking stuck, etc. The effect of improving safety and reducing failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Specific embodiments of the present disclosure will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present disclosure, and are not intended to limit the present disclosure.

[0039] In the present disclosure, unless stated otherwise, the used orientation words such as "upper" and "lower" usually refer to the definition based on the drawings of the corresponding drawings, and "axial" usually refers to the As far as the connecting column is concerned, "inner" and "outer" refer to the axial direction of the connecting column, the end close to the connecting ear is "inner", and the end far away from the connecting ear is "outer". In addition, the term used in this disclosure The terms "first", "second", etc. are used to distinguish one element from another, and do not have order or importance. In addition, when the following descript...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap