Double-half outer ring joint bearing

A joint bearing and semi-outer ring technology, applied in the field of bearings, can solve problems such as cracking, easy deformation of the bearing, weak bearing capacity of the outer ring, etc., and achieve the effect of convenient and quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

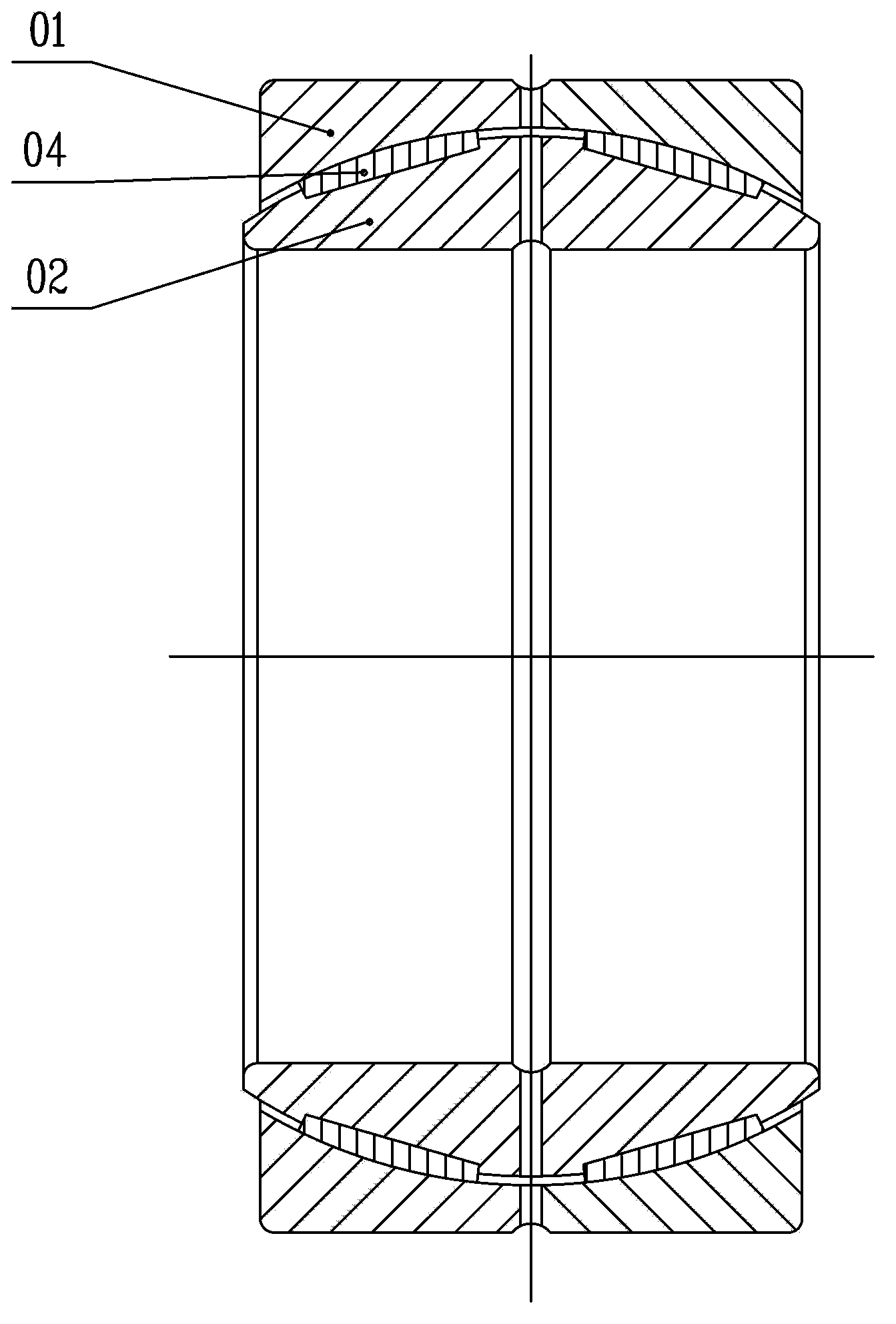

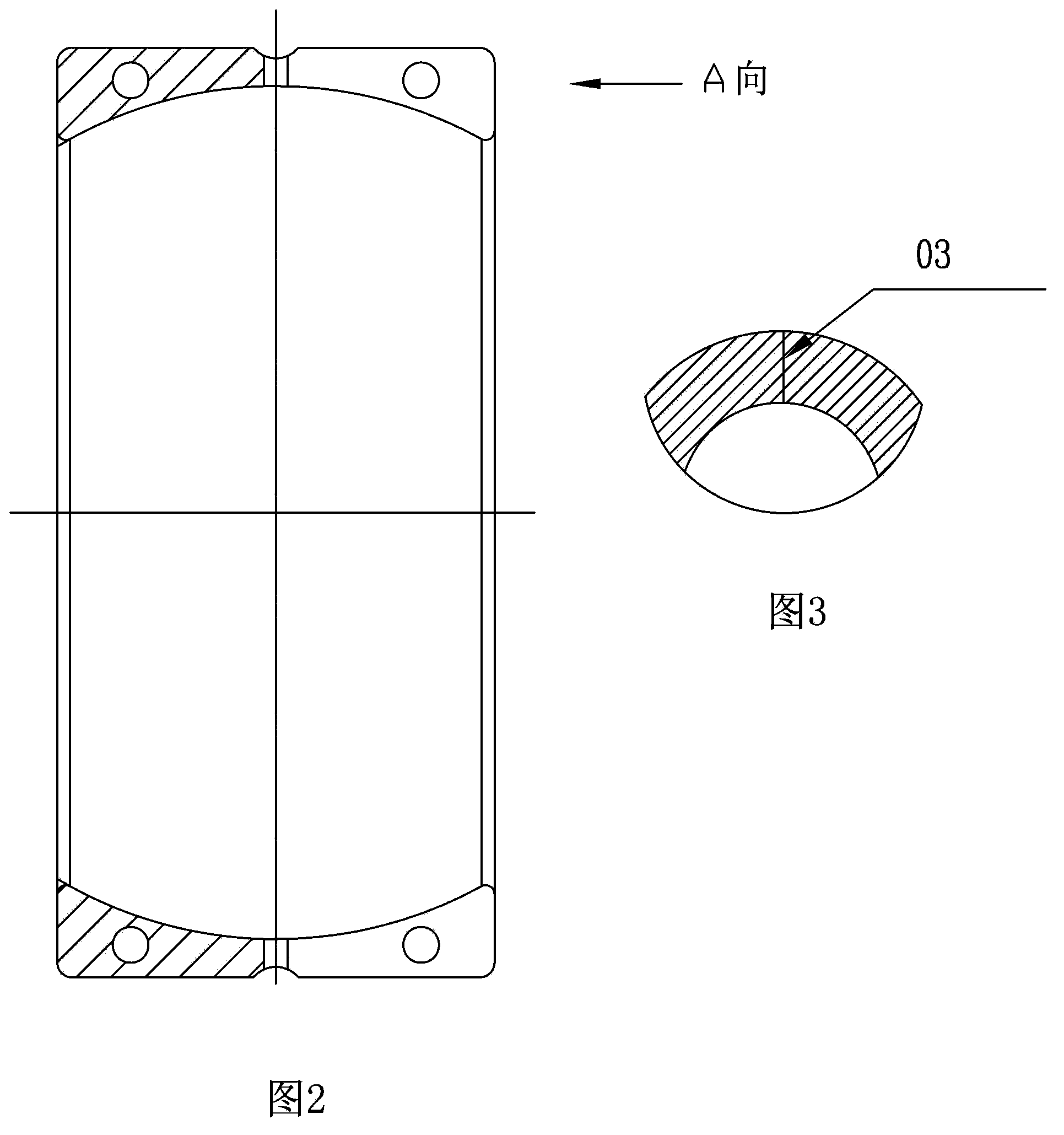

[0011] Such as Figure 1-3 The double half outer ring joint bearing shown includes the outer ring 01, the inner ring 02 and the inner block 04 between them. The present invention changes the previous single-cut press-in method of joint bearings, the outer ring is axially cut into two halves by wire cutting, and the inner ring is assembled on the outer ring during installation and the two halves are screwed together The outer rings are connected together. image 3 In the middle, the number 03 is the cutting point of the end face line (cut through).

[0012] The above are only preferred specific embodiments of the present invention, but the scope of protection of the present invention is not limited to this. Anyone familiar with the technical field within the technical scope disclosed in the present invention, according to the technical solution of the present invention Equivalent replacements or changes to its inventive concept should all fall within the protection scope of the pres

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap