Coated powder, coating composition, and coated article

a coating composition and coating technology, applied in the field of film coating powders, coating compositions and coated materials, can solve the problems of inability to monitor the actual film thickness, the theoretical analysis is not necessary for accurate analysis, and the refractive index value of the final film coating substrate may be remote from the intended valu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Coating Composition Containing Large Color Shift Oxide Film-Coated Aluminium Powder

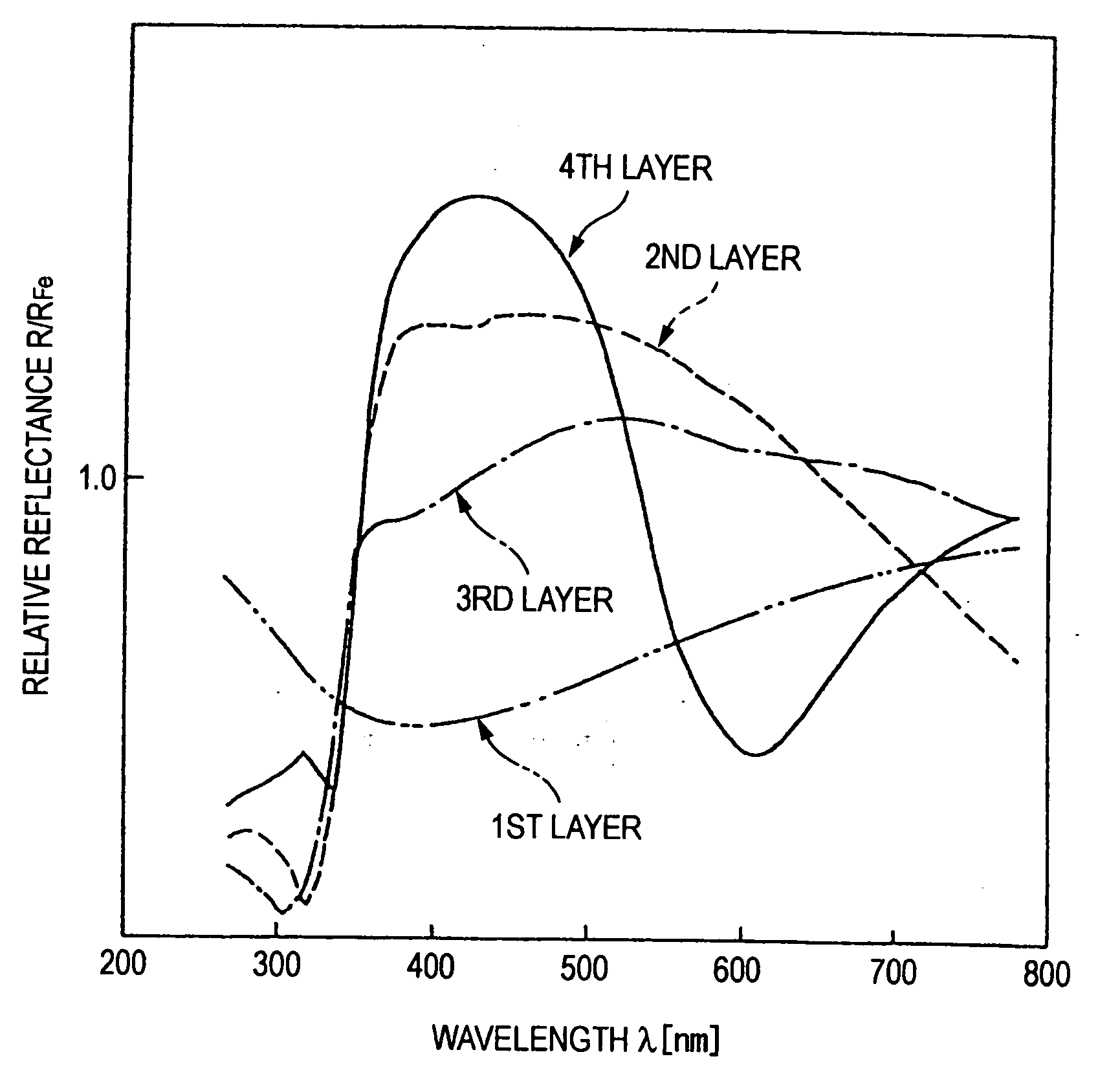

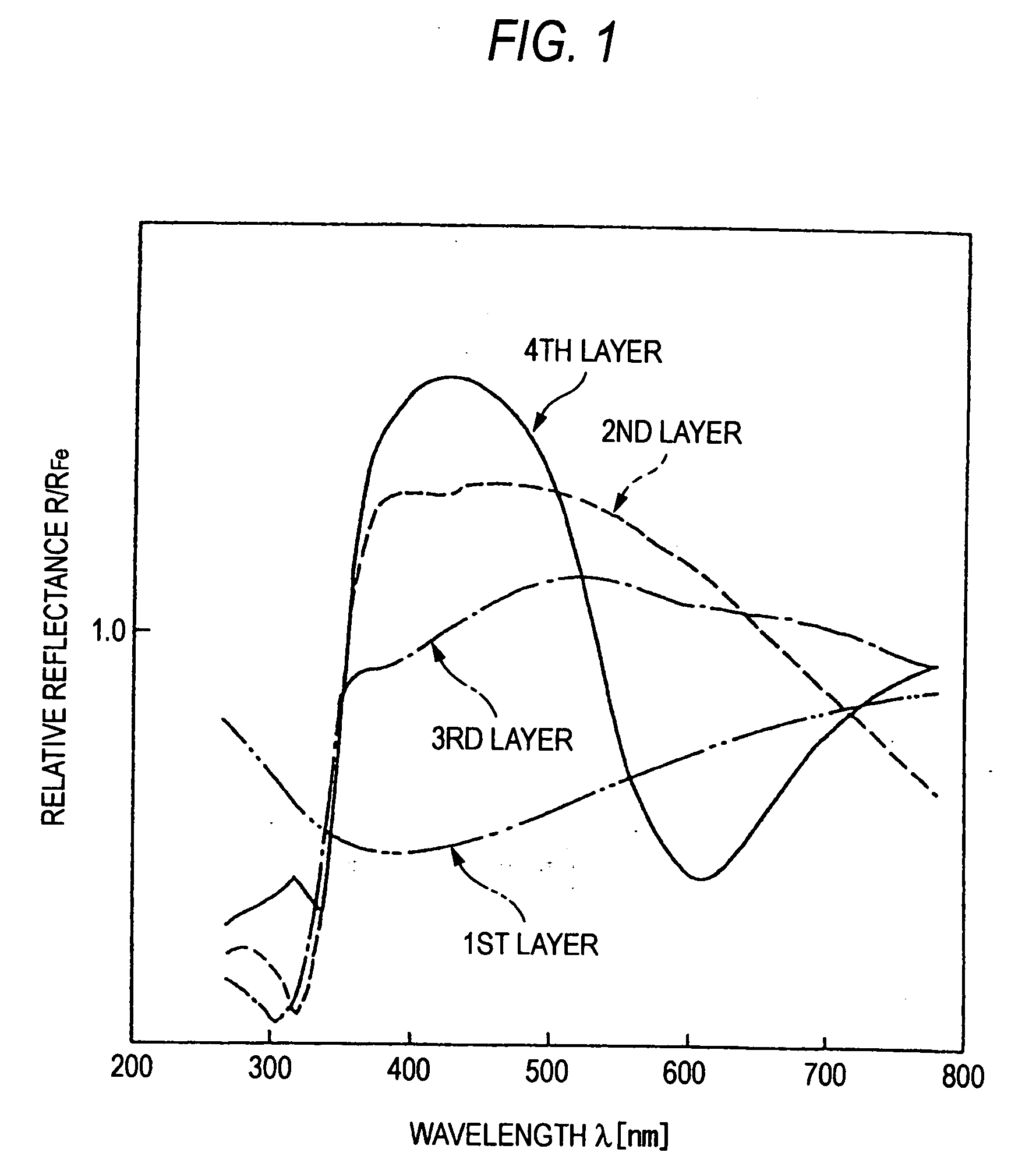

[0243] This was so planned that the vertical reflected color could be red and the reflected color to 50-degree incident light could be blue.

(Formation of First Layer Titania Film)

[0244] In a separable flask, 50 g of granular aluminium powder was dispersed in a liquid that had been previously prepared by adding 17.9 g of titanium isopropoxide to 198.3 g of ethanol, and then, with stirring, a solution that had been previously prepared by mixing 30.4 g of pure water with 47.9 g of ethanol was dropwise added thereto, taking 1 hour. After the addition, this was reacted at room temperature for 5 hours. After the reaction, this was diluted and washed with enough ethanol, then filtered, and dried in a vacuum drier at 110° C. for 3 hours to obtain a titania-coated granular aluminium powder A1.

[0245] The titanium oxide film-coated powder A1 was pale red, having a peak wavelength of the reflection spectral cur

example 2

Oxide Film-Coated Aluminium Powder

[0274] This was so planned that the vertical reflected color could be yellow.

(Formation of First Layer Silica Film)

[0275] 3751 g of the buffer solution 1 that had been previously prepared and 313 ml of pure water were added to 20 g of tabular aluminium powder (mean particle size, 8.5 μm ), and while exposed to ultrasonic waves in an ultrasonic bath at 28 kHz and 600 W, this was stirred and dispersed in the buffer solution 1 containing aluminium powder. 1400 ml of an aqueous sodium silicate solution that had also been previously prepared was gradually added to it at a rate of 2.67 ml / min, and a silica film was deposited on the surface of the powder.

[0276] After the addition of the aqueous sodium silicate solution, this was further reacted for 2 hours and the unreacted materials were all reacted.

[0277] After the film formation, the silica film-coated powder-containing slurry was subjected to repeated decantation with enough water and washed.

[027

example 3

Catalyst Coating Composition With White Mica

(Formation of First Layer Titania Film)

[0299] 20 g of substrate particles of spherical white mica powder (mean particle size, 13.3 μm) were well dispersed in 2662 ml of the buffer solution 2 in an ultrasonic bath. Next, the liquid temperature was kept at 50 to 55° C., and 58 ml of an aqueous titanyl sulfate solution that had been previously prepared was gradually and dropwise added to it at a constant rate of 1.8 ml / min. After the addition, this was further reacted for 2 hours to obtain a titania-coated white mica powder Cl.

(Formation of Second Layer Silica Film)

[0300] 15 g of the titania-coated white mica powder Cl was further coated with a silica film. The amount of the buffer solution was 3751 ml, and an aqueous sodium silicate solution was dropwise added to it at a rate of 40 ml / min so as to form a coating film. This was reacted for 2 hours until any unreacted matter did not remain therein, and washed in the same manner as above

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Nanoscale particle size | aaaaa | aaaaa |

| Nanoscale particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap