Combustion furnace

A technology of combustion furnace and combustion tower, which is applied in the field of combustion furnace to achieve the effect of eliminating hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

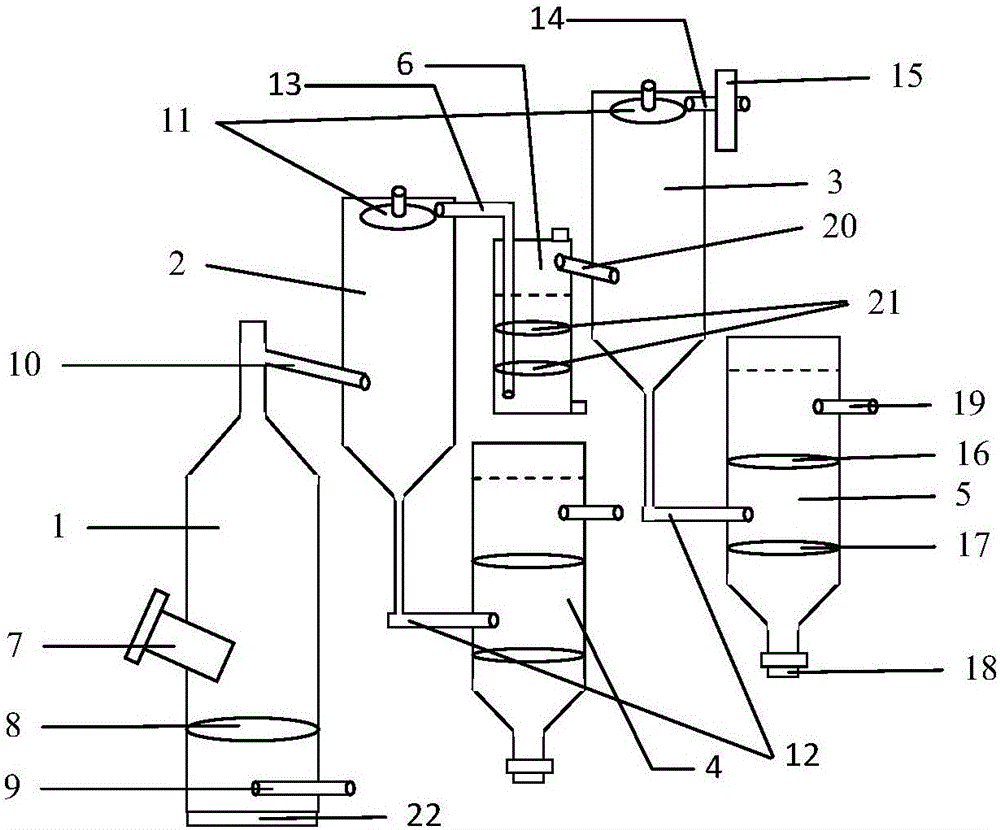

[0031] In the figure, the coal is placed on the coal planting net (8) through the coal inlet (7), the air required for combustion is provided by the air inlet (9), and it is burned in the combustion tower (1), and the smoke and waste gas generated by the combustion pass through The flame outlet (10) is discharged into the first sprinkler tower (2), and the shower (11) connected to tap water sprays the smoke and exhaust gas, and the smoke is washed into the water flow and discharged into the first sedimentation tank through the tower drain pipe (12). (4), under the filtering effect of the filter membrane (16), the dust of PM2.5 remains under the membrane, and the dust removal water flow is discharged through the pool drain pipe (19), and the isolation net (17) can reduce the scouring effect of the water flow on the bottom sludge . The exhaust gas that has been rinsed for the first time is passed into the solution of the drug pool (6) through the drug spraying connecting pipe (13),

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap