Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Shear wall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In structural engineering, a shear wall is a vertical element of a seismic force resisting system that is designed to resist in-plane lateral forces, typically wind and seismic loads. In many jurisdictions, the International Building Code and International Residential Code govern the design of shear walls.

Wavelike steel plate and concrete combined shear wall

InactiveCN101922187AEffective energy dissipationHigh resistance to lateral forceConstruction materialWallsSheet steelWave shape

The invention discloses a wavelike steel plate and concrete combined shear wall, which belongs to the technical field of structural engineering. The wavelike steel plate and concrete combined shear wall is characterized by consisting of a wavelike steel plate, concrete, a reinforcing fabric, shear-resistant studs and connecting plates, wherein the shear wall is embedded into an edge frame; the connection modes of the wavelike steel plate and the edge frame are divided into two modes that: if the edge frame is a steel frame, the wavelike steel plate is welded with the edge steel frame at the periphery; and if the edge frame is a concrete frame, the wavelike steel plate is first welded with the four connecting plates at the periphery and then connected with the edge frame through the shear-resistant studs on the connecting plates. The outer surface of the wavelike steel plate on the side with concrete is provided with the shear-resistant studs, and the concrete is poured after the reinforcing fabric is arranged, so that the wavelike steel plate and concrete combined shear wall can be obtained.

Owner:TSINGHUA UNIV

Arc-shaped mold plate for casting arc-shaped shear wall of industrial factory building and manufacture method of arc-shaped mold plate

InactiveCN102505839AImprove thermal insulationGood lookingForms/shuttering/falseworksEngineeringBatten

The invention relates to an arc-shaped mold plate for casting an arc-shaped shear wall of an industrial factory building. The arc-shaped mold plate comprises arc-shaped net frames, battens and an arc-shaped mold plate body, wherein the arc-shaped net frames, which are the same in shape, are fixedly mounted on the arc-shaped mold plate; the battens are vertically and fixedly mounted between the arc-shaped net frames and the arc-shaped mold plate body in the cross direction; and the distance between each two adjacent battens is 300 mm. The invention further provides a manufacture method of the arc-shaped mold plate, which mainly comprises the steps: (1), processing a wood mold plate into the arc-shaped mold plate according to the shape of the arc-shaped shear wall; (2), processing the arc-shaped net frames; (3), fixing the battens in such a manner that the 50 multiplied by 100mm battens are vertically fixed on the arc-shaped net frames and the distance between each two adjacent battens is 300 mm, so that the battens and the arc-shaped net frames form an integral body; and (4), forming the arc-shaped mold plate for casting the arc-shaped shear wall of the industrial factory building. The arc-shaped mold plate has the advantages that the structure is simple; the design is scientific and reasonable; the weight is light; the cost is low; the assembly is convenient; the cost of hoist equipment during mounting is effectively reduced; and the use is safe and reliable.

Owner:MCC TIANGONG GROUP

Construction method for concrete shear wall

InactiveCN103741846AReduce construction costsShort construction periodWallsHeat proofingFiberCalcium silicate

Owner:山西省第二建筑工程公司

Heat-preservation wall body of wood-frame shear wall

InactiveCN101929207AQuality improvementHigh precisionWallsClimate change adaptationWall studEngineering

The invention belongs to the technical field of structural engineering, and particularly relates to a heat-preservation wall body for a mixed structure of a wood frame and a wooden shear wall, and assembly technology. The assembled heat-preservation wall body consists of wall studs, a wood base structural slab, a gypsum board, heat-preservation cotton, a wood-frame pillar, a mudsill board and a top beam board, wherein a horizontal interval between every two adjacent wall studs is 400 to 600 millimeters, and the wall studs on both sides are connected with the wood-frame pillar through nails; the wood base structural slab covers the wall body, is connected with the wall studs, the top beam board and the mudsill board through the nails, and is flush with the outer side of the wood-frame pillar; the gypsum board is covered on the inner side of a wallboard and is connected with the wall studs through screws; and the heat-preservation cotton is filled between inner and outer cladding boards. Materials for the assembled wall body provided by the invention can improve the natural environment in the process of growth, have the advantages of low energy consumption in the machining process, regeneration and natural degradation after abandonment, and have the functions of quick construction, vibration prevention, energy conservation, heat preservation, heat insulation and the like; the heat-preservation wall body has the advantages of high industrial production degree, high production efficiency, less on-site wet operation, a plurality of operational surfaces and quick construction; and the materials, such as dimension stocks, connectors, plywood, laminated wood and the like can be localized to reduce the construction cost.

Owner:TONGJI UNIV

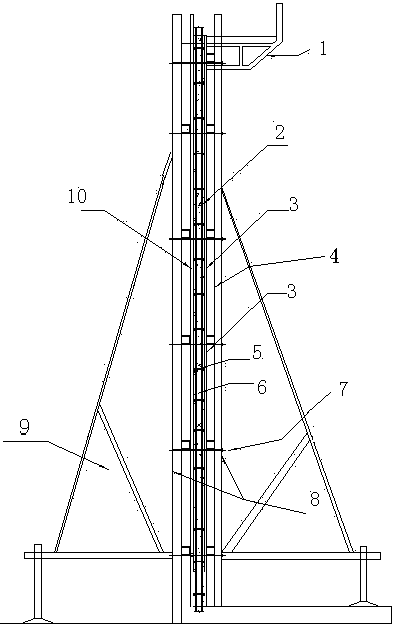

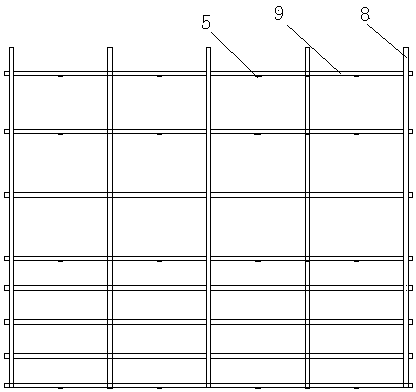

Steel bar and angle iron truss welding device and construction method thereof

ActiveCN108500492AGuaranteed dimensional accuracyReduce welding costsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringRebar

The invention relates to steel bar and angle iron welding construction in a novel steel plate combined shear wall structure, is mainly applied to steel bar and angle iron welding construction in the novel steel plate combined shear wall structure, and belongs to the field of steel structures. A steel bar and angle iron truss is included and internally provided with a pneumatic clamping assembly, arotary positioning assembly and a steel bar guiding and positioning assembly, wherein the rotary positioning assembly is arranged on the left side of the pneumatic clamping assembly, and the steel bar guiding and positioning assembly is arranged on the right side of the pneumatic clamping assembly. According to a steel bar and angle iron truss welding device and a construction method thereof, thestructure is compact, operation is convenient, and the structure is firmer.

Owner:浙江东南网架股份有限公司

Construction method for dry and wet type composite connecting assembly-type building

ActiveCN108755926AImprove seismic performanceEasy hanging installationBuilding constructionsComposite constructionFloor slab

The invention provides a construction method for a dry and wet type composite connecting assembly-type building. The construction method comprises the following steps that components are prefabricatedin a workshop, wherein the components include vertical columns, crossbeams, floor slabs, shear wall inner layers and shear wall outer layers; joints of the vertical columns are located between the floors, sleeving-connection steel pipes are arranged in the vertical columns, vertical column reinforcements are arranged on the peripheries of the sleeving-connection steel pipes, and the vertical columns are adjusted to be perpendicular and coaxial; the ends of the sleeving-connection steel pipes are positioned in a mutual sleeving-connection mode and are fixedly connected, the vertical column reinforcements are connected in a welded mode or connected through sleeves, and transverse reinforcements are bound; the shear wall inner layers and the shear wall outer layer are hoisted, and the transverse reinforcements of shear walls and the transverse reinforcements of the vertical columns are connected in a welded mode or connected through sleeves; formworks are erected at the joints, the joints of the vertical columns and inner cavities of the shear walls are poured into a whole; meanwhile, the crossbeams are hoisted to be placed on bracket supports, and corner connecting pieces are mounted; the floor slabs are hoisted on the crossbeams; and the steps are sequentially circulated, and composite construction of the assembly-type building is completed. According to the construction methodfor the dry and wet type composite connecting assembly-type building, compressive strength can be improved, and the anti-seismic property is improved.

Owner:CHONGQING JIKAI TECH SERVICE CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap