Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Precast concrete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Precast concrete is a construction product produced by casting concrete in a reusable mold or "form" which is then cured in a controlled environment, transported to the construction site and lifted into place ("tilt up"). In contrast, standard concrete is poured into site-specific forms and cured on site. Precast stone is distinguished from precast concrete using a fine aggregate in the mixture, so the final product approaches the appearance of naturally occurring rock or stone. More recently expanded polystyrene is being used as the cores to precast wall panels. This is lightweight and has better thermal insulation.

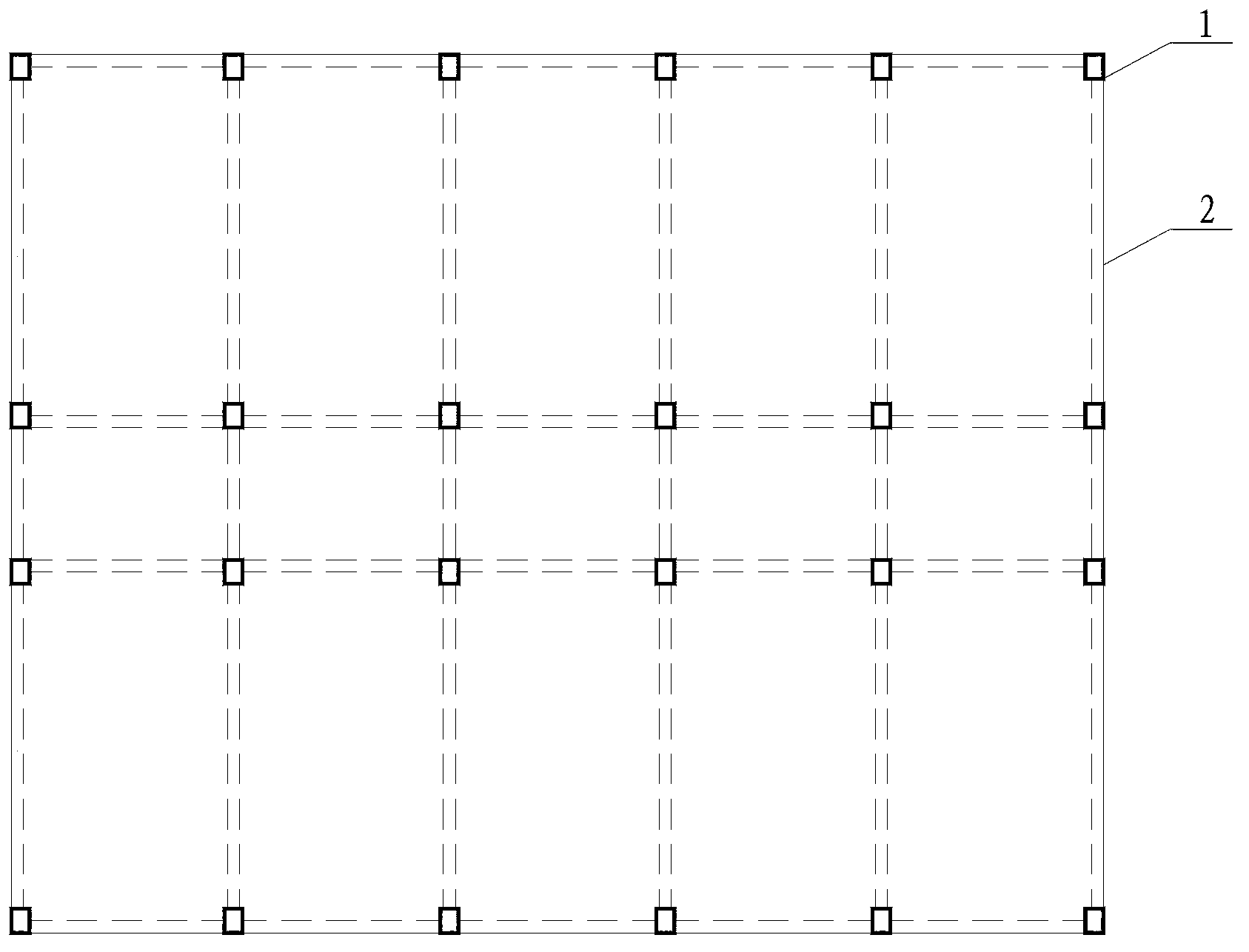

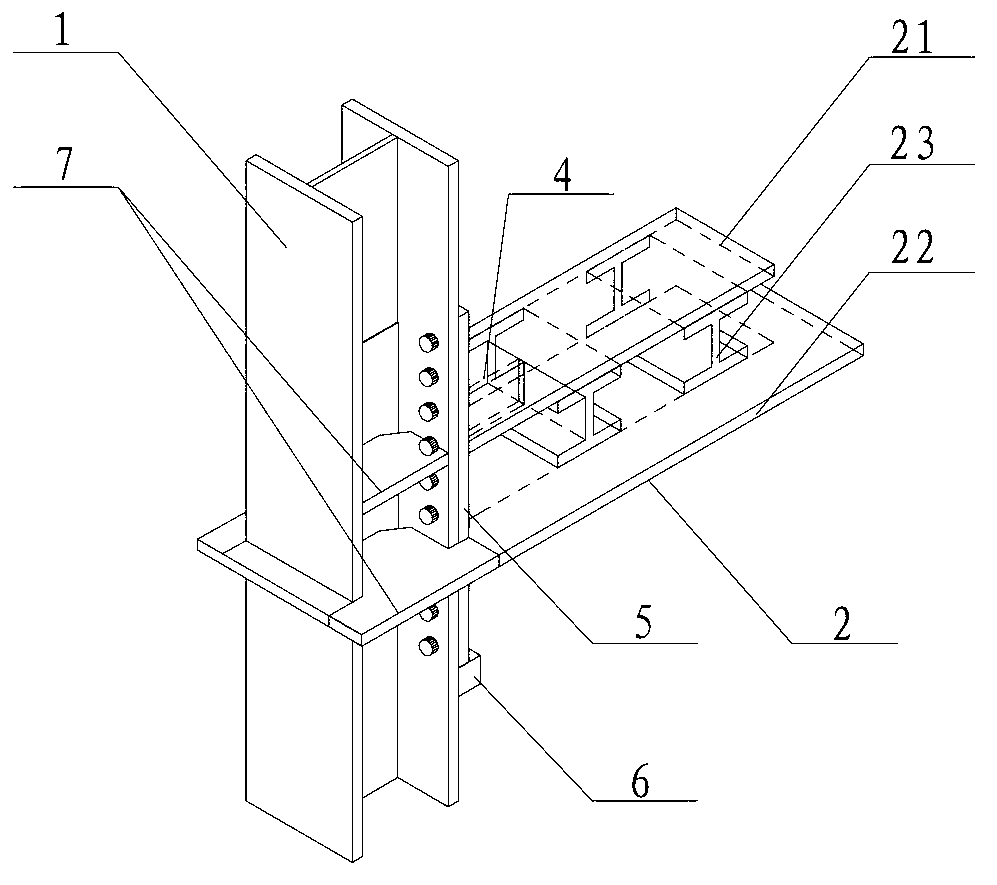

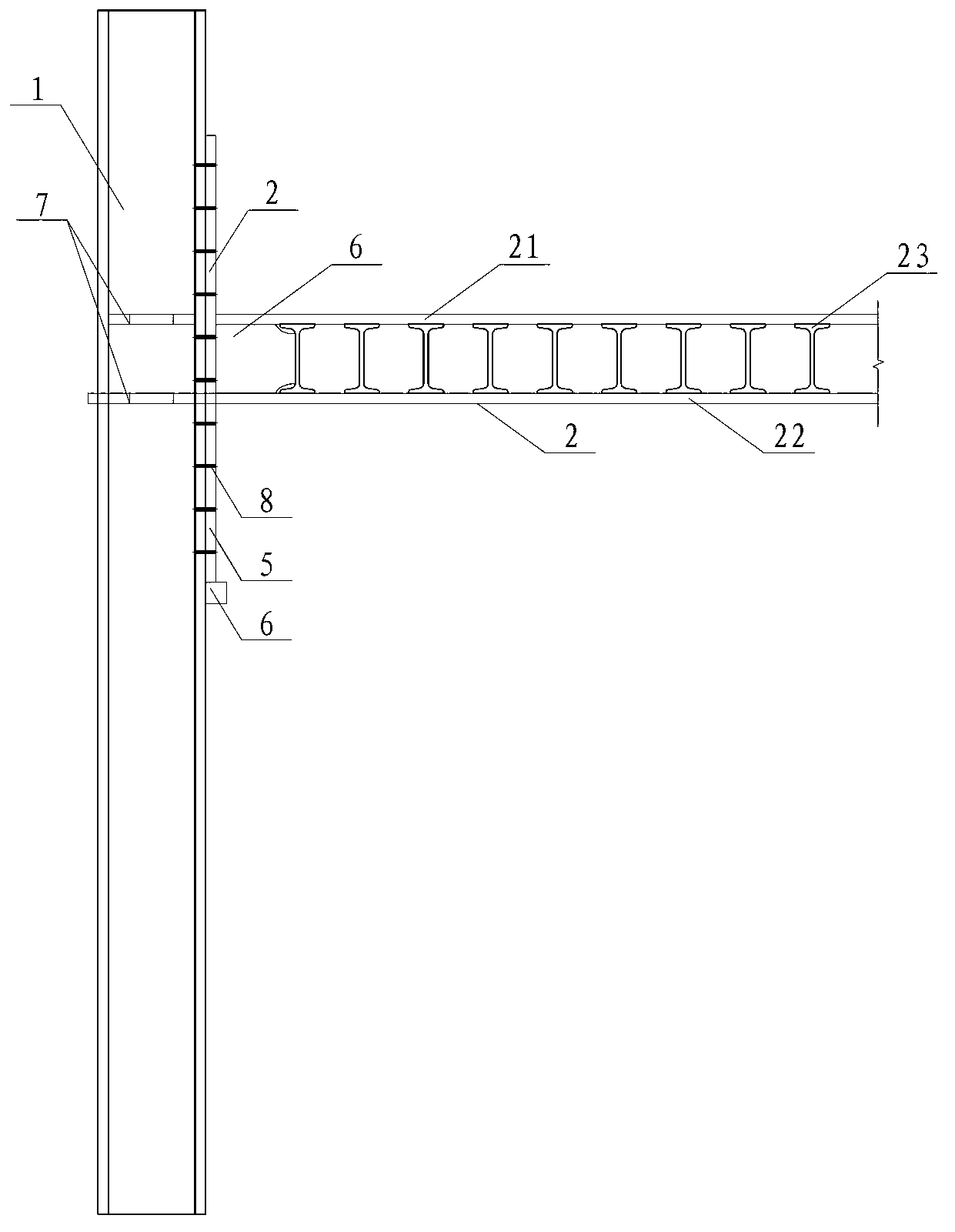

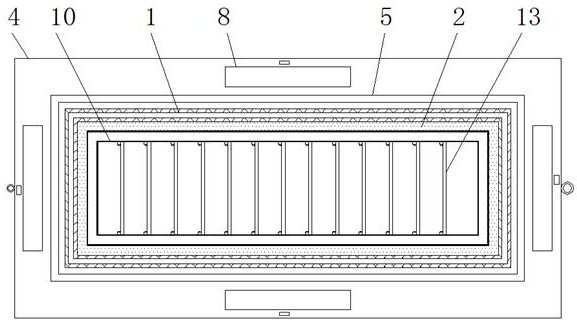

Steel-concrete slab-column structure system

ActiveCN103276795AReasonable structureConvenient on-site operationFloorsSteel columnsPrecast concrete

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

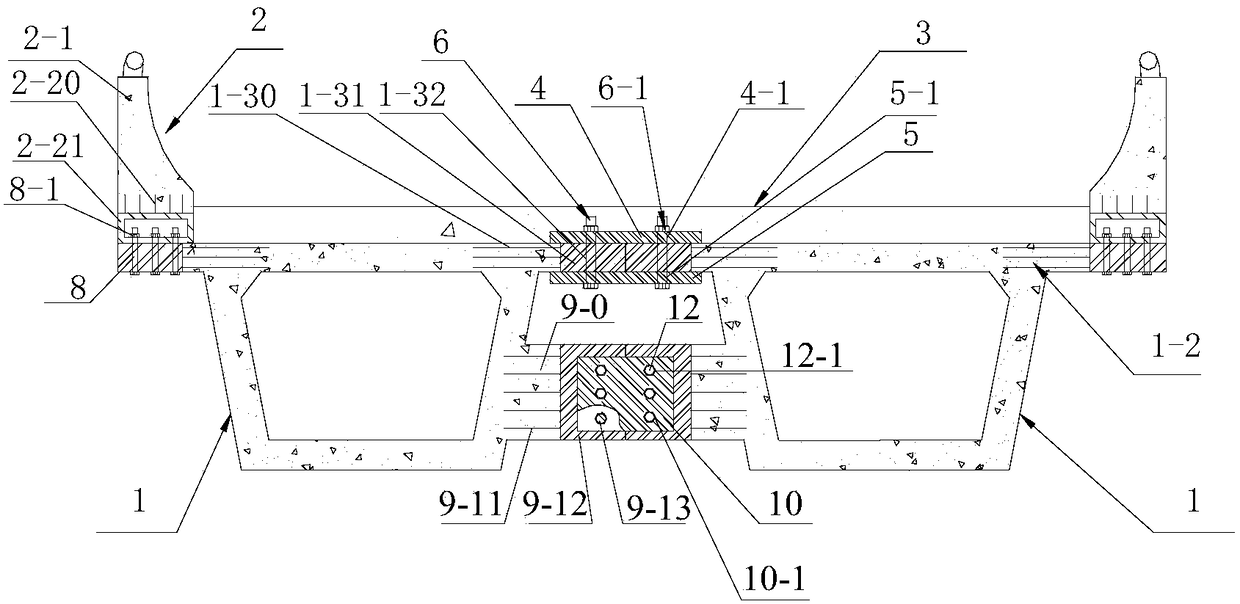

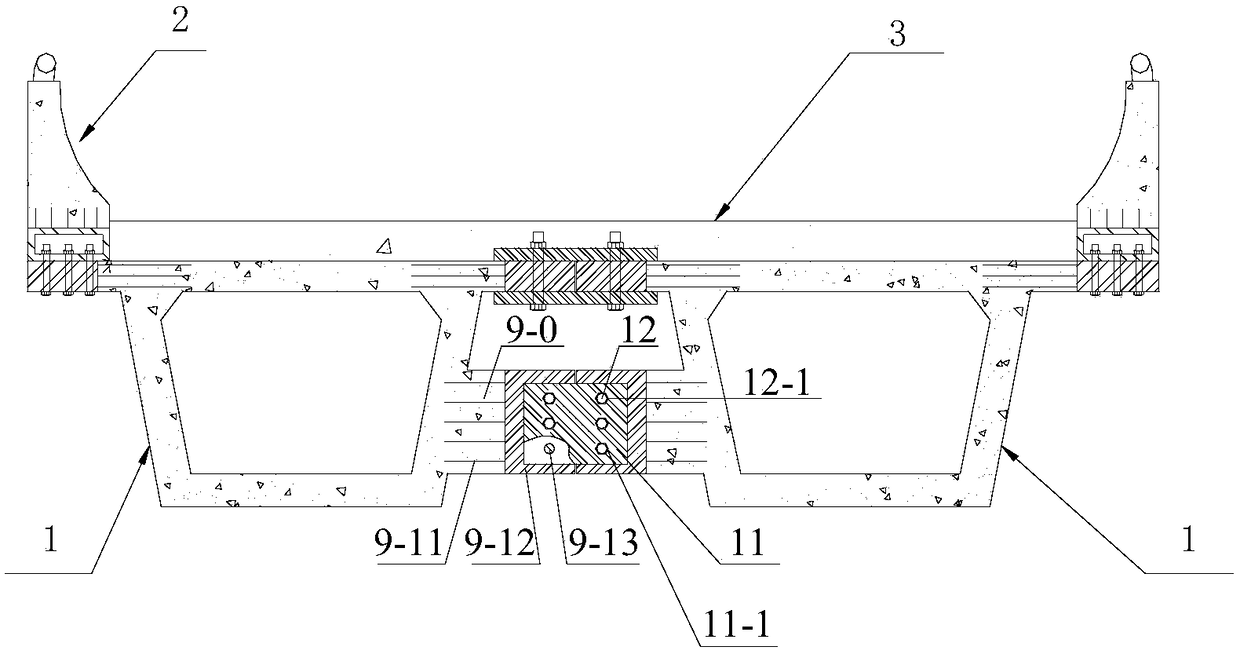

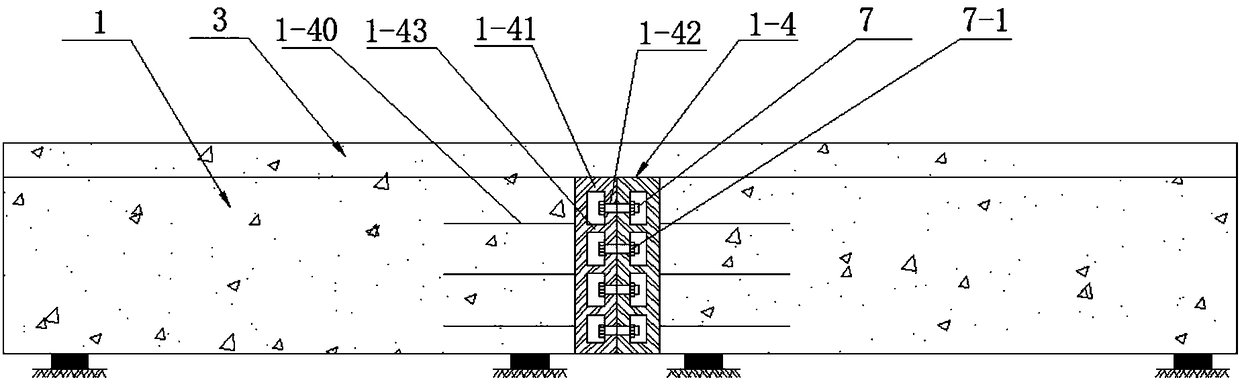

Fully-assembled prefabricated concrete girder bridge superstructure and construction method thereof

PendingCN108589507AAvoid conversionLong construction periodBridgesBridge deckPre embedding

Owner:HEBEI UNIV OF TECH

Novel dry type welded joint of fabricated concrete continuous beams

The invention discloses a connecting joint of a prefabricated concrete continuous beams and the connecting joint can be used for connecting the joints of a prefabricated frame structure, and belongs to the technical field of fabricated concrete structure in structural engineering. The connecting joint is characterized by comprising a steel covering plate, a pre-buried steel plate, epoxy resin adhesive and reinforced concrete continuous beams, wherein a testing beam is prefabricated in a factory, two prefabricated beam sections are bonded by the epoxy resin adhesive, and after intensity is achieved, the pre-buried steel plate is spliced with the steel covering plate in a welding mode. The welded joint is suitable for prefabricating the concrete fabricated continuous beams structure, and hasthe advantages of being convenient to construct and environment-friendly and saves energy; and the requirement of sustainable development is met.

Owner:NORTHEAST FORESTRY UNIV

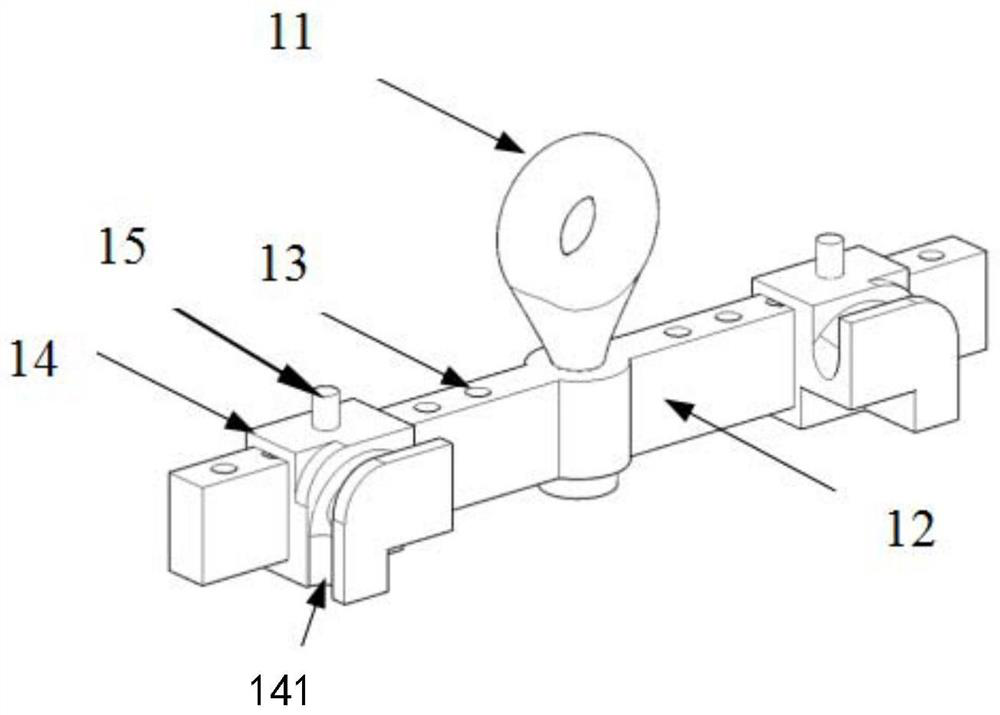

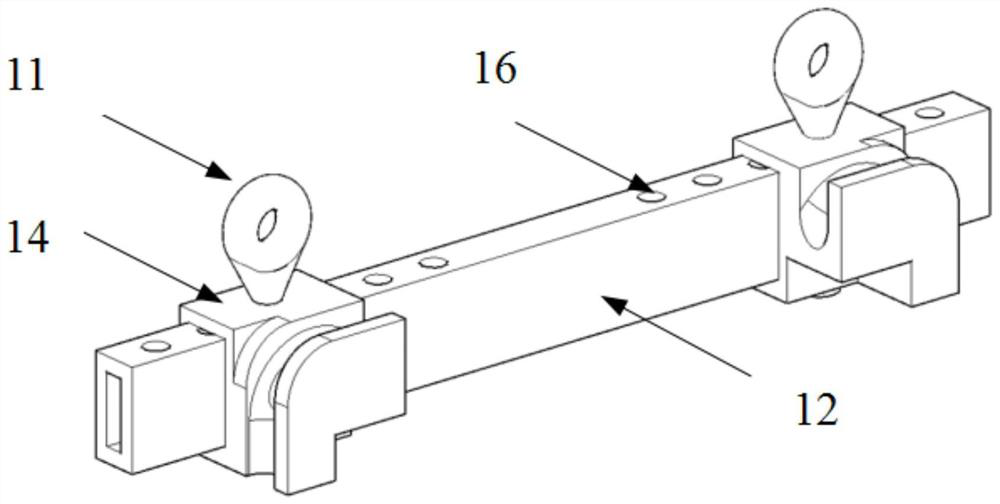

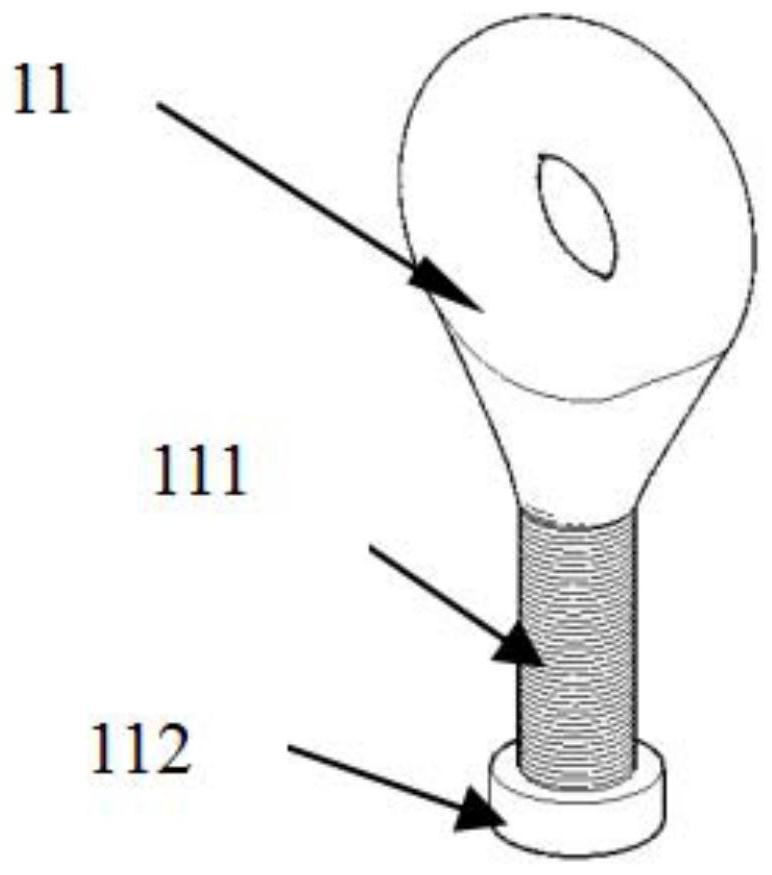

Connecting piece and end plate of full-thread prefabricated concrete member and using method of connecting piece and end plate

The invention provides a full thread type prefabricated concrete member connecting piece which comprises an inner connecting fastener, a bolt and a supporting nut, the inner connecting fastener is located on the inner side of a prefabricated concrete member and used for connecting end plates of adjacent prefabricated concrete members, a threaded hole is formed in the inner connecting fastener, a threaded rod of the bolt is in a full thread type, and the supporting nut is arranged in the threaded hole. The tail of the bolt sequentially and transversely penetrates through the supporting nut and the end plate from the outer side to the inner side and is in threaded connection with the threaded hole of the inner connecting fastener. The connecting piece can be used for connecting the precast concrete members from the inner side, and the technical obstacle that the precast concrete members cannot be connected from the inner side due to insufficient space is overcome.

Owner:GUANGDONG SANHE PILE CO LTD

Anti-collision power distribution cabinet for municipal engineering

PendingCN114122953ASubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsPrecast concreteVehicle detector

Owner:杨州伟

A composite concrete member and its construction method

ActiveCN111980217BImprove the ability to withstand shear stressPrecise positioningWallsBuilding material handlingArchitectural engineeringRebar

This application relates to a composite concrete component, belonging to the field of concrete components, which includes a prefabricated concrete component and a rear concrete component, and a support mechanism is provided in the superimposed part between the prefabricated concrete component and the rear concrete component, so The supporting mechanism includes a strengthening component for resisting shear force and a positioning component for positioning the rear reinforcement. This application has the effect of improving the problem of insufficient shear force resistance.

Owner:FENGHUA XIAOYUN CONSTR ENG CO LTD

Pre-embedded-free multi-functional lifting appliance for precast concrete beam

PendingCN111908318AReduce use costImprove general performanceLoad-engaging elementsConcrete beamsConstruction engineering

Owner:江苏沛丰建筑工程有限公司

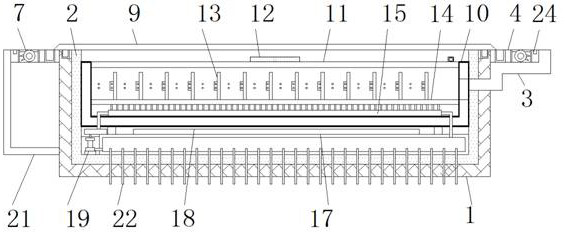

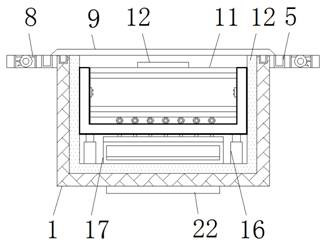

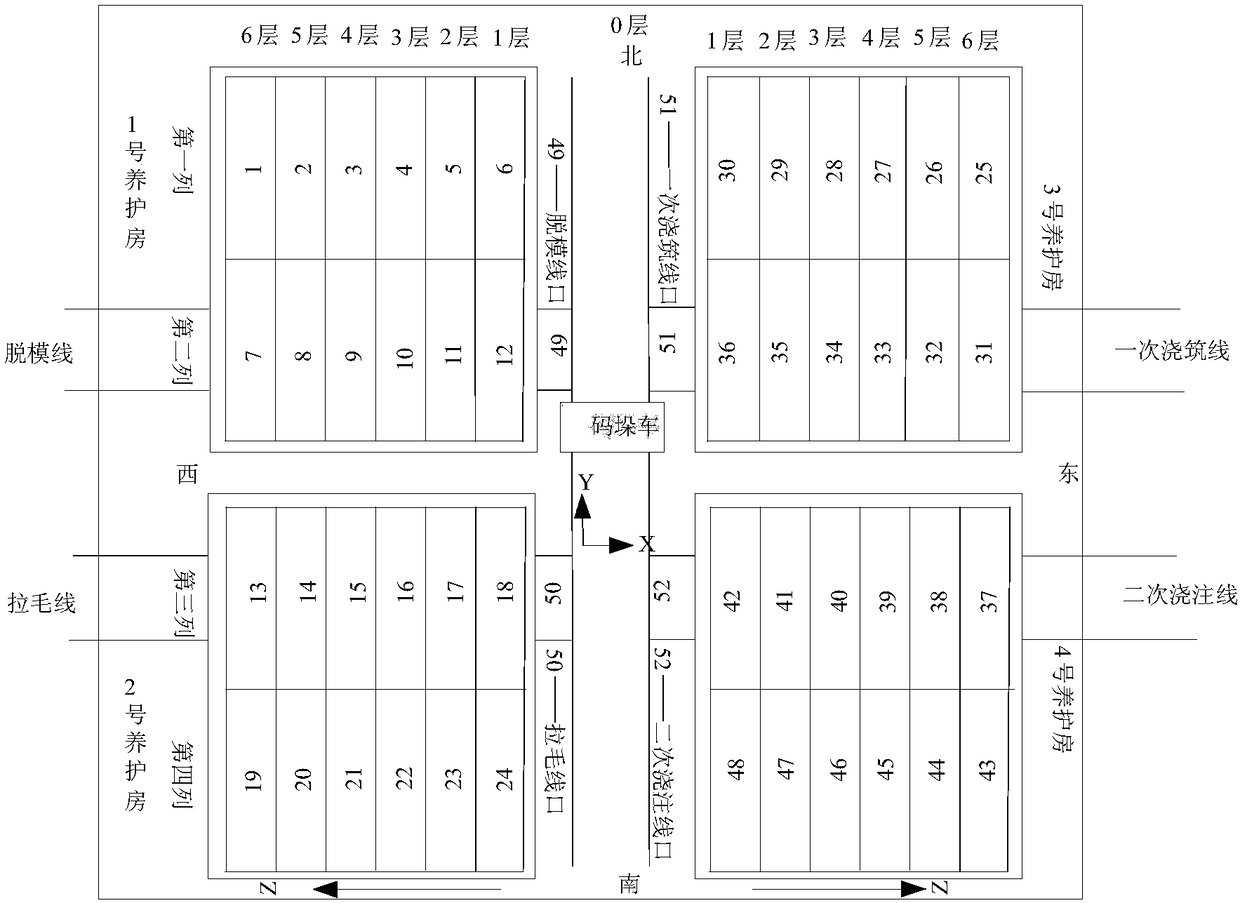

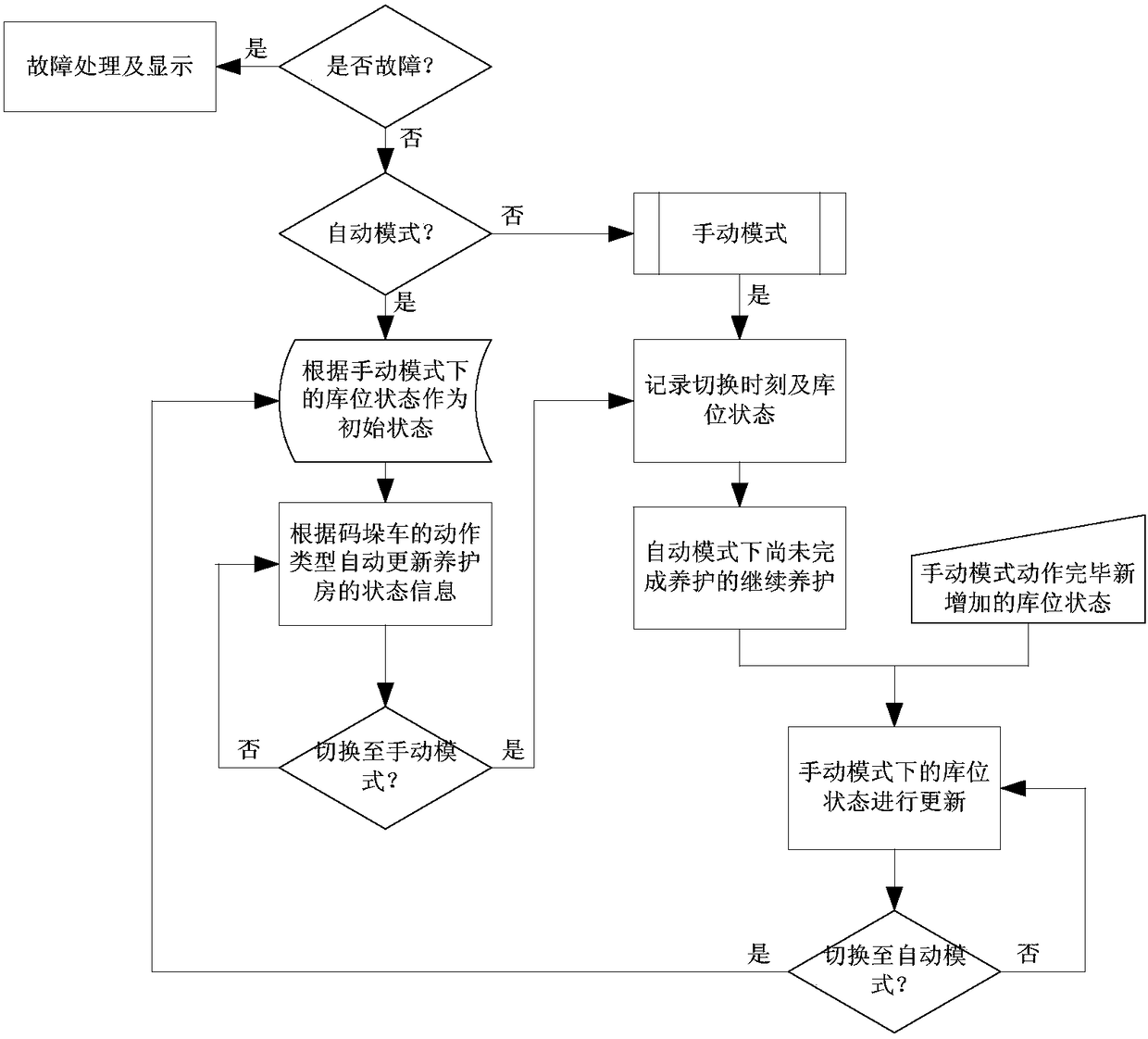

Maintenance state control system and control method in the maintenance room of the concrete precast slab production line

ActiveCN105739470BThe maintenance status is clear and controllableIncrease productivityControl devices for conveyorsStacking articlesProduction lineMode control

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

Preparation method of prefabricated concrete member

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap