Maintenance state control system and control method in the maintenance room of the concrete precast slab production line

A state control and control system technology, applied in the direction of comprehensive factory control, electrical program control, comprehensive factory control, etc., can solve the problems of insufficient maintenance state management, low degree of automation, and inability to meet product maintenance well, and achieve The maintenance status is clear and controllable, improving the product qualification rate and ensuring the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

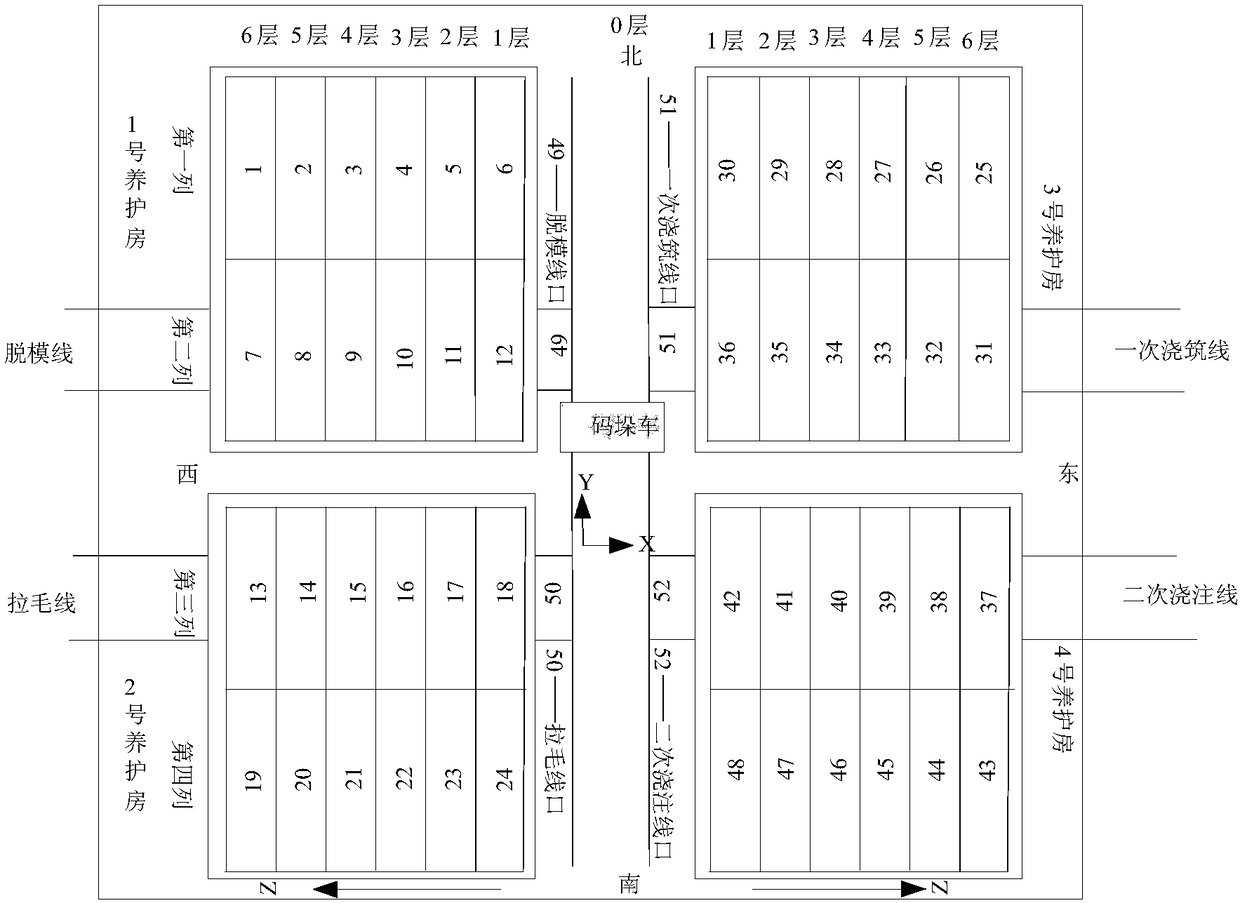

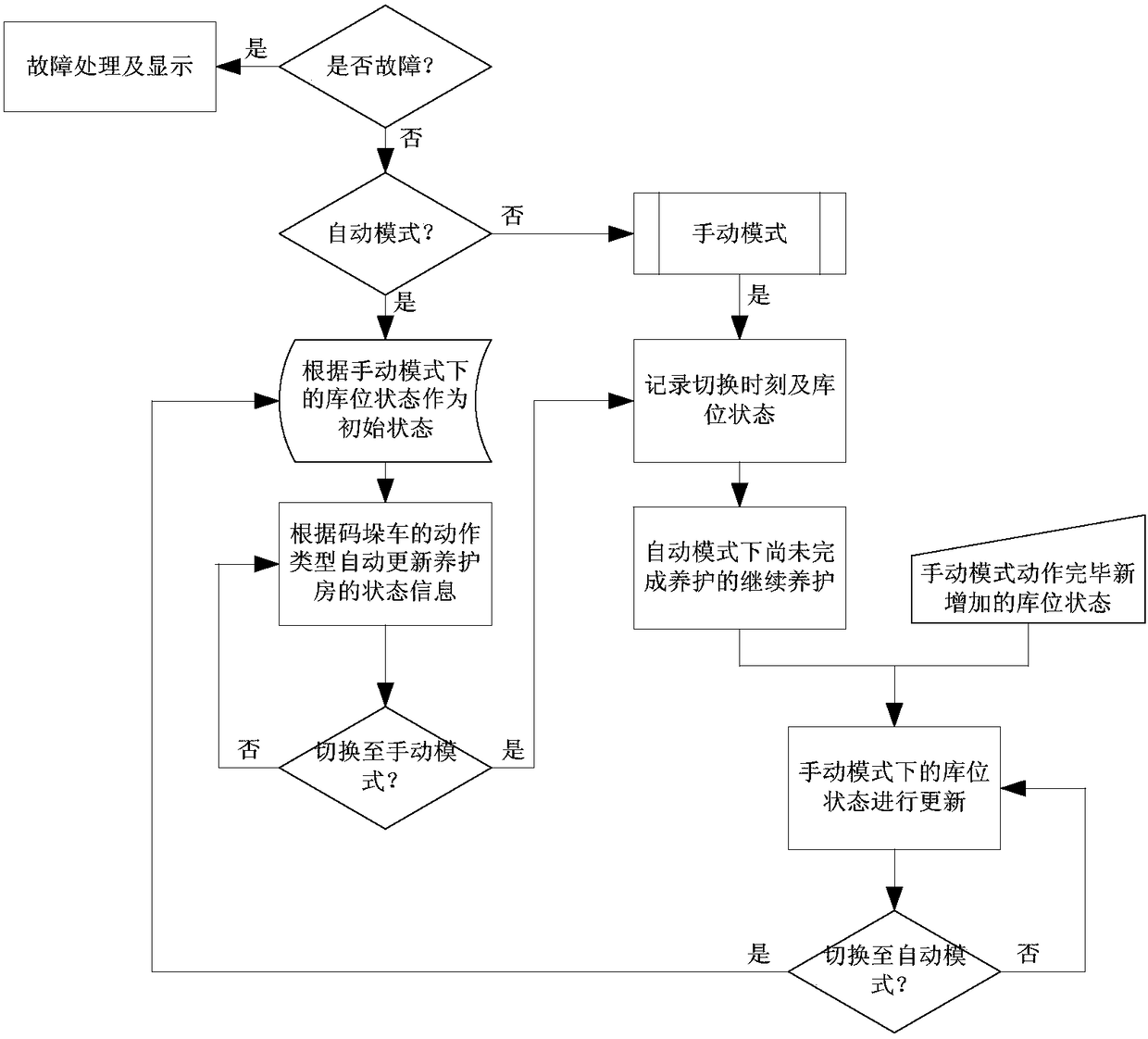

Embodiment

[0050] In this embodiment, the human-computer interaction display unit 1 is a window for parameter input. The parameters include the control mode (automatic or manual) of the maintenance room, the time of the first maintenance and the second maintenance, and the initial value of the status of the maintenance room. At the same time, the human-computer interaction display Unit 1 is also the window for troubleshooting and displaying the status of the maintenance room. Before the system runs, workers only need to input parameters in the corresponding position to confirm and save.

[0051] The main controller PLC 2 includes a fault processing module 21, a stacking truck control module 22, and a maintenance room state control module 23, whose functions are respectively processing faults, controlling the palletizing truck 3, and controlling the state of the maintenance room; wherein the functions of the palletizing truck 3 are Complete the transfer of the mold table, that is, control the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap