Fully-assembled prefabricated concrete girder bridge superstructure and construction method thereof

A prefabricated concrete and girder bridge technology, applied in bridges, buildings, etc., can solve the problems of long construction period, high labor intensity, and low work efficiency, and achieve the effect of avoiding the transformation of the force system, high labor intensity, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

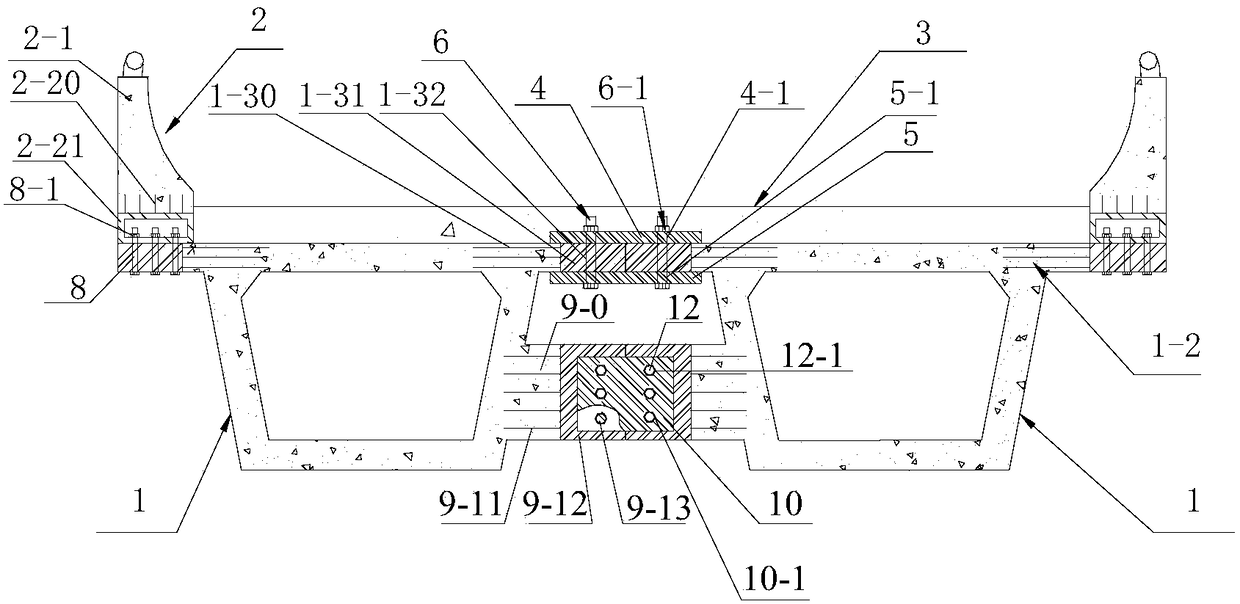

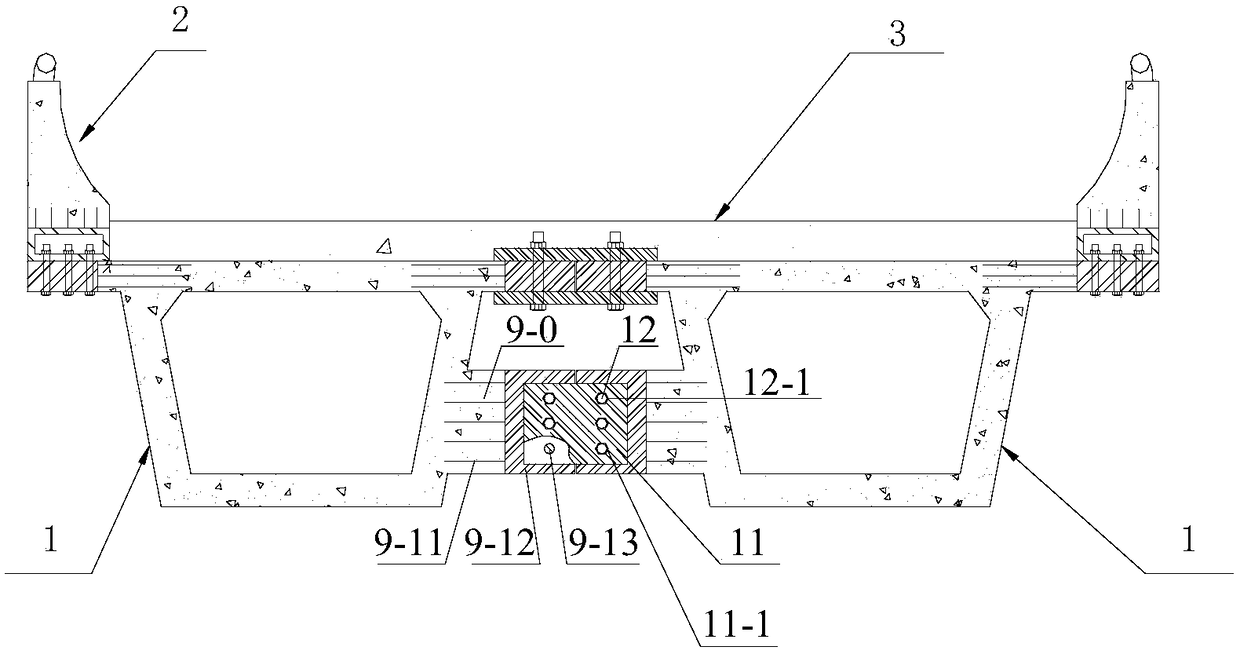

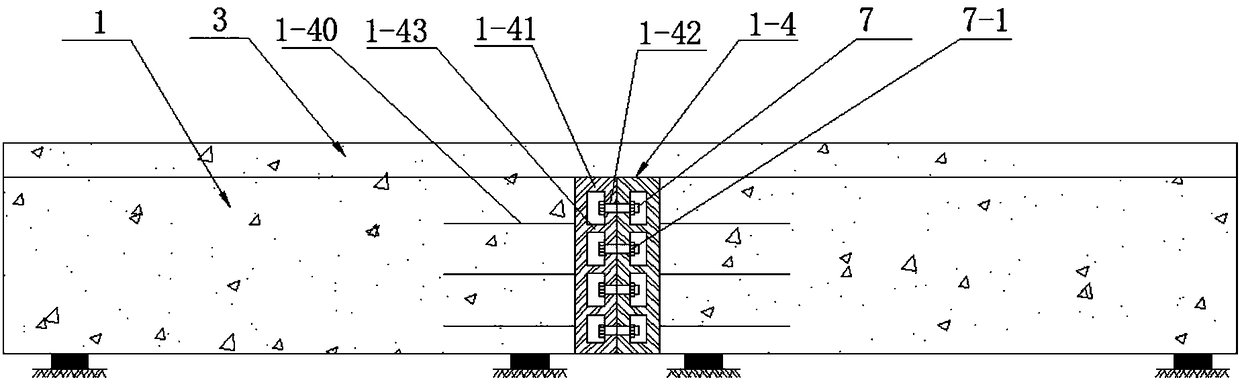

[0033] see Figure 1 to Figure 5 , a fully assembled precast concrete girder bridge superstructure, which is formed by splicing several precast concrete box girder monomers 1, precast concrete guardrails 2 are arranged on both sides of the bridge deck, bridge deck pavement 3, and the precast concrete box The beam monomer 1 includes a precast concrete box girder body 1-1, and flange plates 1-2 are arranged on both sides of the top plate of the precast concrete box girder body, and the laterally spliced rigid prefabricated parts 1-3 are pre-embedded in the flange plates, The transverse splicing rigid prefabricated part 1-3 includes a transverse splicing embedded connector 1-30 and a transverse splicing connecting seat 1-31, and the transverse sp

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap