Novel fabricated steel-concrete combined steel plate beam

A prefabricated, concrete technology, applied in the direction of bridges, bridge parts, bridge materials, etc., can solve the problems of large maintenance workload, complicated construction, complicated structure, etc., and achieve the effect of improving durability, good landscape effect, and simplifying structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

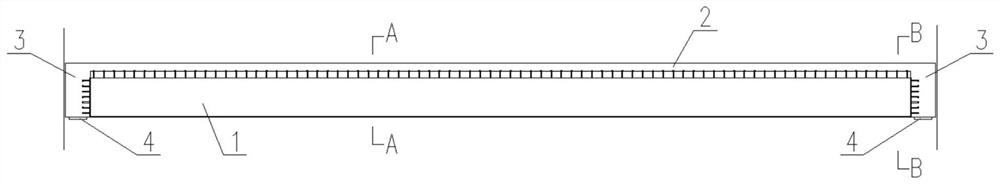

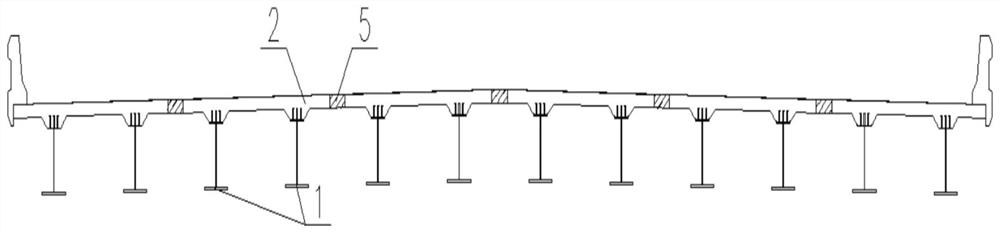

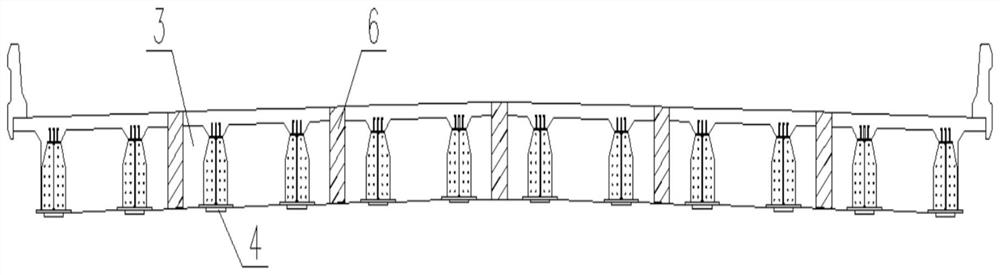

[0028] Such as Figure 1-Figure 5 As shown, a new type of prefabricated steel-concrete composite steel plate girder includes at least one "π"-shaped beam composed of two I-shaped beams 1 and a panel 2, and the end of the "π"-shaped beam is covered with a beam 3. The bottom end of the "π"-shaped beam is provided with a support 4, and the panel wet joint 5 and the beam wet joint 6 formed between the "π"-shaped beams are respectively provided with structural stress ribs, and the "π"-shaped beam is erected on site After that, the panel wet joint 5 and the beam wet joint 6 are poured on site.

[0029] The I-shaped beam 1 is a steel structure, and the panel 2 and the beam 3 are both concrete structures.

[0030] The beam 3 is outsourced on the outside of the I-shaped beam 1 .

[0031] The support 4 is arranged at the bottom end of the I-shaped beam 1 .

[0032] The number of "π"-shaped beams is determined by the width of the road. A single "π"-shaped beam is made by processing two s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap