Device for detecting the state of steel-reinforced concrete construction parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

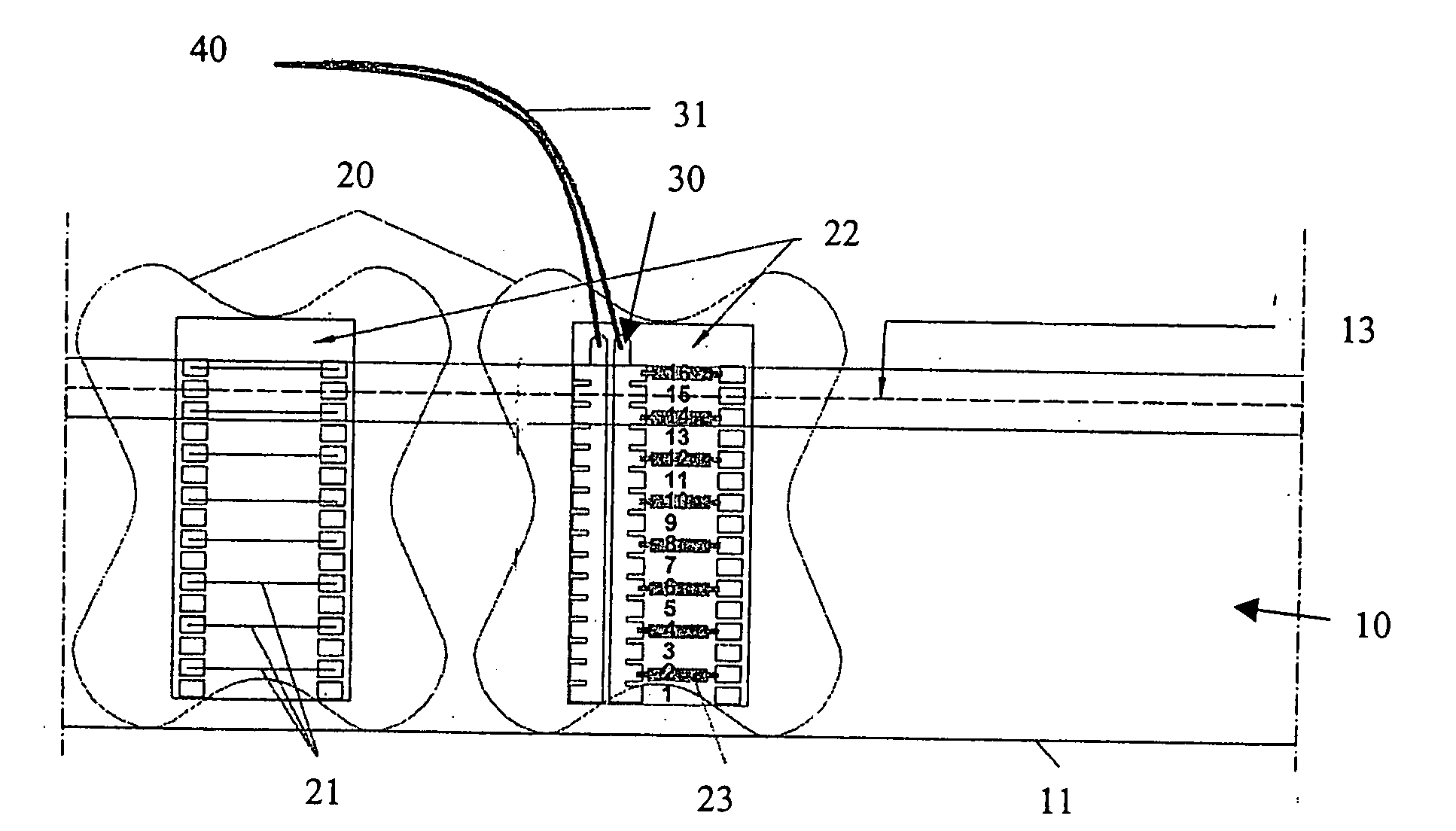

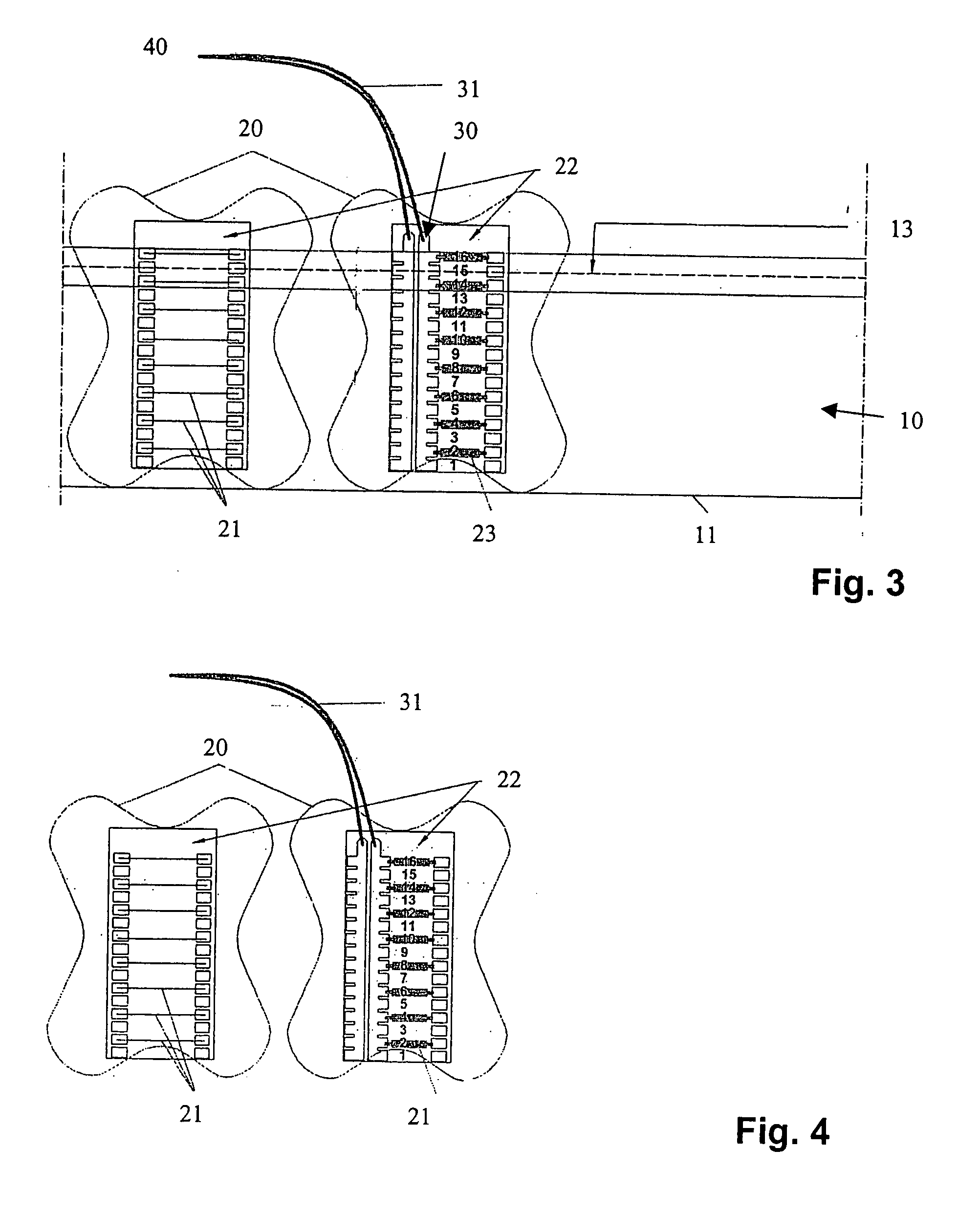

[0053]In FIG. 3, the invention is shown schematically in more detail. Here, an embodiment is involved that is suitable for initial installation. This means that this device for detecting the state of steel-reinforced concrete construction parts 10 will be incorporated from the beginning by sealing it in during the production of the concrete construction part.

[0054]A concrete construction part 10 in turn can be seen schematically. A surface 11 of concrete construction part 10 is shown at the bottom in this case and the concrete construction part 10 can continue toward the top in the drawing to an extent that is selected arbitrarily.

[0055]In concrete construction part 10 there is found a reinforcement bar 13, which in this case—as also in practice—extends frequently inside it, usually parallel to the surface 11 of the concrete construction part 10. The progression of a depassivation front from the surface 11 of the construction part into the concrete construction part 10 will now be moni

second embodiment

[0069]a device according to the invention is shown in FIG. 5. This embodiment is suitable for the case of later installation. That is, it is frequently also of interest to equip an already existing concrete construction part 10 with this device at a later time for such detection of [corrosion] states. In this case, a drilled hole 15 must be introduced into the inside of concrete construction part 10 through the surface 11. Insofar as this is possible, this drilled hole should not destroy or attack the steel reinforcement 13 itself, but should be suitable for introducing the device for detecting the state of the steel-reinforced concrete construction part 10 according to the invention to a sufficient depth.

[0070]Such a device is prefabricated in this case, whereby a serial production is possible without anything further. Here, a mortar pin 25 is used as support 20, and this can be particularly well recognized in FIG. 6. This cement mortar pin 25 is approximately semi-cylindrical and is

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap