Steel plate externally-rived stengthening method for reinforced concrete structure and its special-purpose rivet

A reinforced concrete and concrete technology, used in bridge reinforcement, building construction, building maintenance, etc., can solve the problems of difficult quality assurance, uneconomical, poor temperature and weather resistance, and achieve easy quality assurance, low construction cost, and weather resistance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

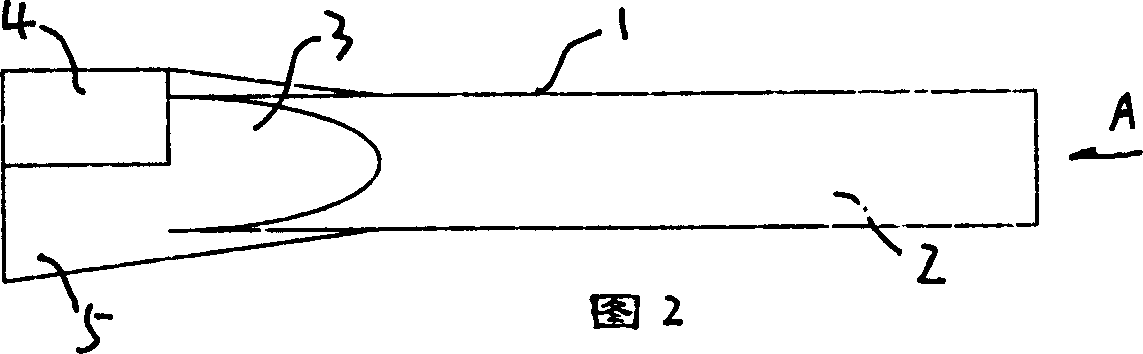

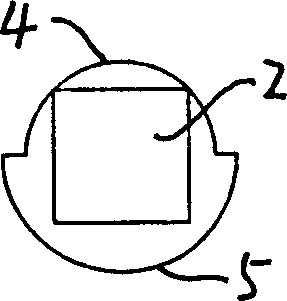

[0085] Specific embodiment 1 is a typical rivet steel reinforcement method 1: using rivet steel reinforcement method to increase the main reinforcement of the beam

[0086] As shown in Figures 8 and 9, the size of the rectangular cross-section lintel is: 120mm (height) × 240mm (width), the span is 2m, the design requires the reinforcement at the bottom of the beam to be 3φ12, and the actual reinforcement is only 2φ6. Now, a 6mm strip is riveted at the bottom Reinforced by 80mm steel slats.

[0087] Steel slat design maximum tensile strength:

[0088] 6mm×(80mm-14mm)×210N / mm 2 =83.16kN, where 14mm is the hole diameter of the steel plate.

[0089] The number of rivets in the 1 / 4 length range at both ends of the steel strip:

[0090] 83.16kN / 20kN=4.15 (pieces), 5 pieces are actually selected, that is, 1 rivet is arranged in a 10cm arrangement, and the design tensile force of each rivet is 20kN.

[0091] The rivets in the middle of the steel strips are arranged according to

Embodiment 2

[0093] Example 2 is a typical reinforcement method 2: using riveted steel reinforcement method to increase the stirrups of the beam

[0094] As shown in Figures 10, 11, and 12, a beam with a rectangular cross-section has a cross-sectional size of 240mm (height) × 120mm (width) and a span of 2m. According to the design requirements, it is necessary to add stirrups within 60cm on both sides of the beam. The amount of added stirrups is 5 φ10 steel bars with a spacing of 150mm to improve the shear resistance of the beam. Now it is reinforced by riveting five 3mm×50mm parallel U-shaped hoop slats at the beam end. The maximum tensile force of the steel slats is:

[0095] 3mm×(50mm-12mm)×210N / mm 2 =23.9kN, where 12mm is the aperture size of the steel plate.

[0096] The number of rivets in the 1 / 4 length range of both ends of the steel plate: 23.9kN / 20kN=1.2 (pieces), actually choose 2, where 20kN is the tensile force of a single rivet.

[0097] The total length of the U-shaped

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap