Modular Integrated Building and Construction Method Thereof

a modular integrated and building technology, applied in building construction, building types, constructions, etc., can solve the problems of large amount of construction rubbish, large disturbance on the daily life of surrounding residents, and large noise and dust pollution, so as to reduce the workload on site and reduce the construction period. , the effect of reducing the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

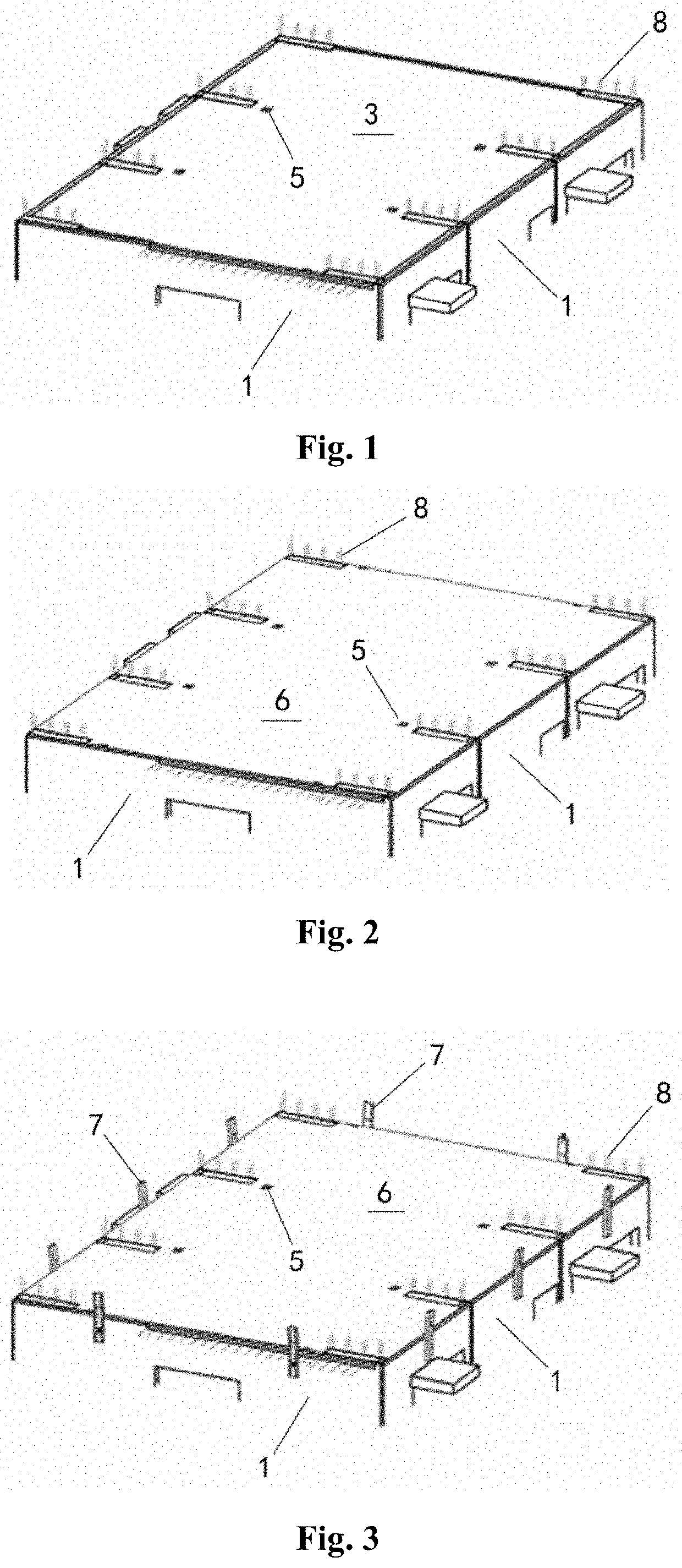

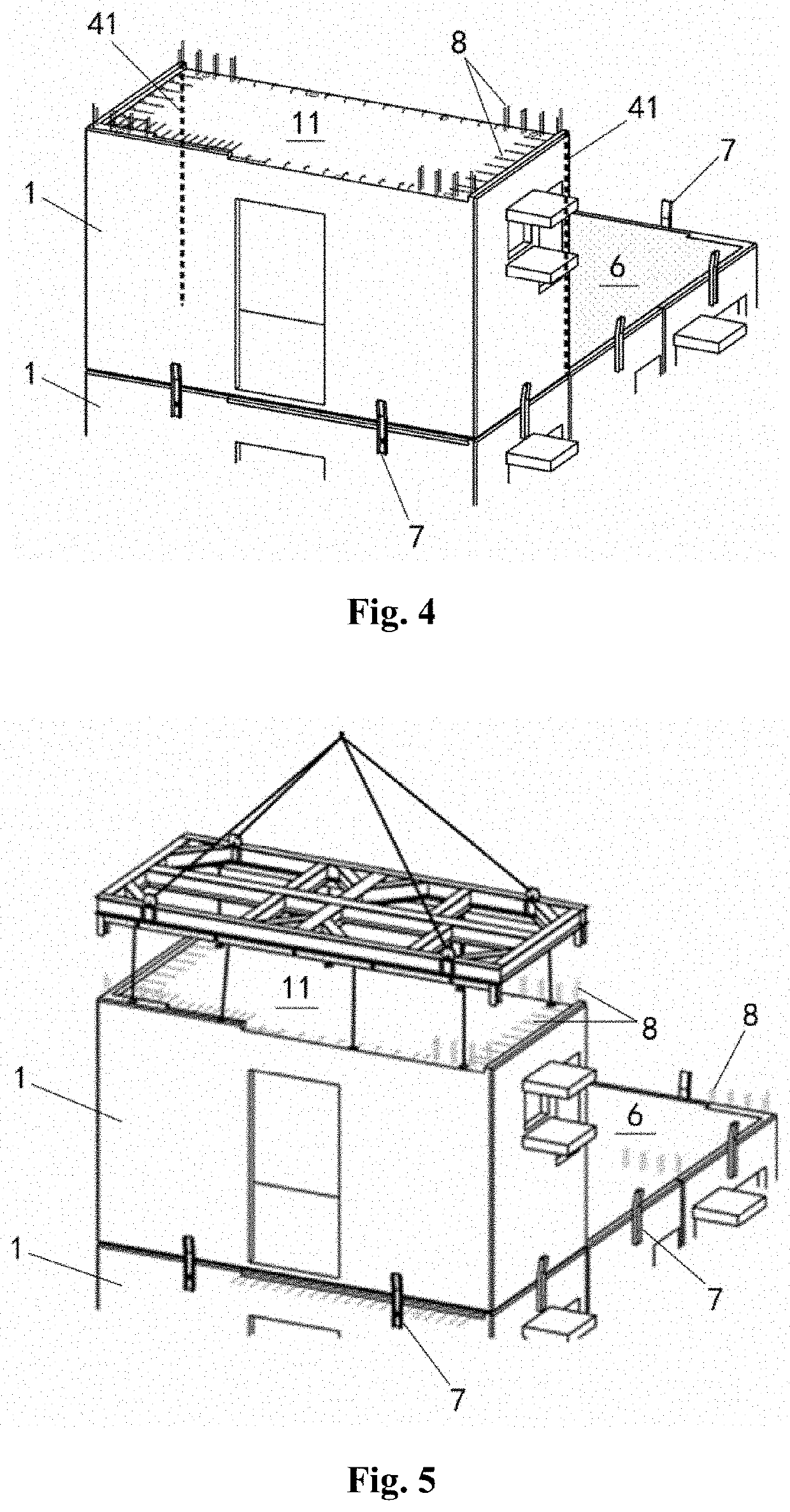

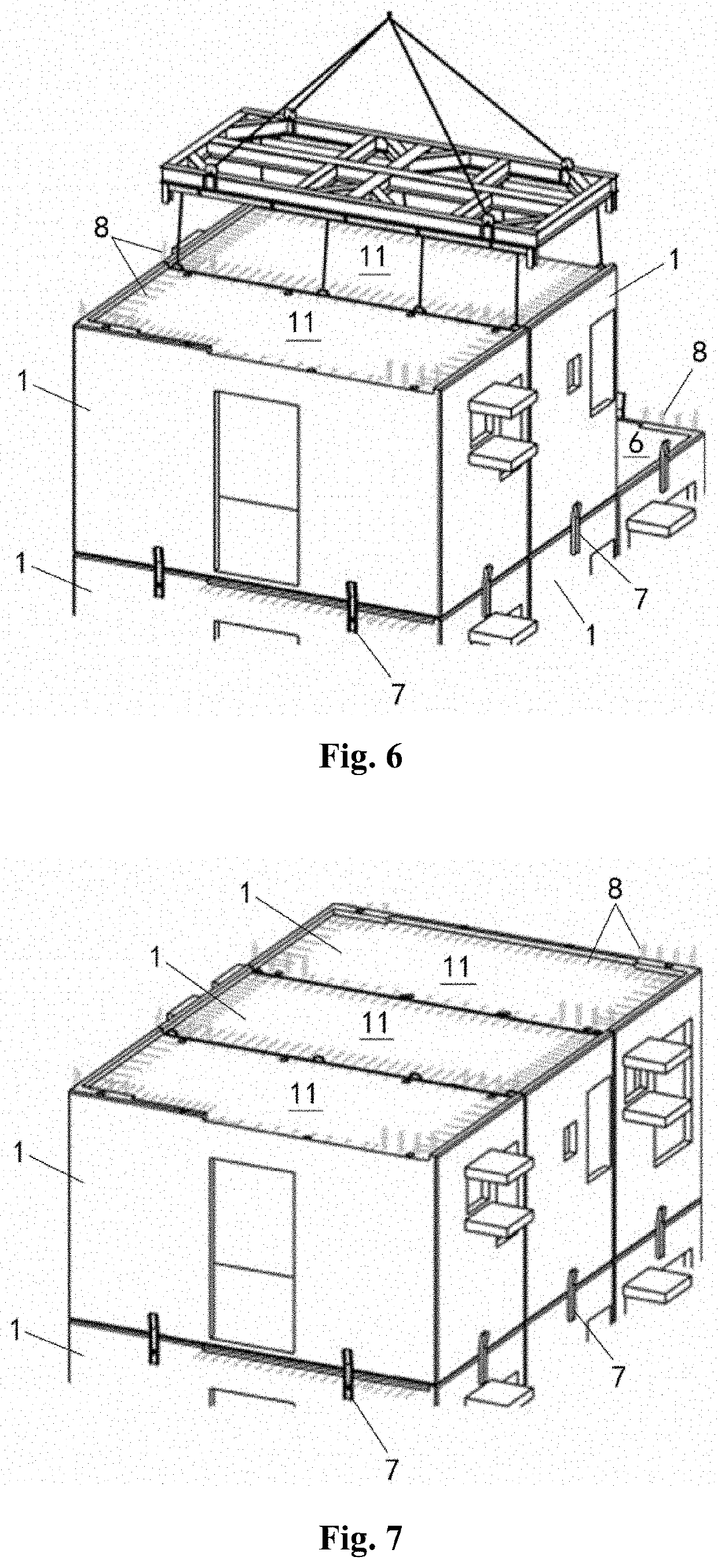

[0033]In the following, the embodiments of the present invention will be further illustrated with reference to the drawings.

[0034]As shown in FIG. 10, a modular integrated building according to the present invention is formed by assembling a plurality of prefabricated room units 1 together. The prefabricated room unit 1 can be a kitchen, a bathroom, a sitting room, a dining room, a bedroom, a storage room, or the like. As shown in FIGS. 11, 12 and 14, the prefabricated room unit 1 as a whole is prefabricated at a factory, integrally with a top plate 11, a bottom plate 12, a wall body 13, a load-bearing structure, etc., and further with structural members such as a door, a window or the like. The prefabricated room unit 1 can be further embedded in advance with electrical conduits, water pipelines, or the like. The load-bearing structure can be a structural wall 14, a beam 15, an upright post or the like, which is provided therein with reinforcing bars. The prefabricated room unit 1 is

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap