Paving construction process for roofs of steel framework composite building

A construction technology and building technology, applied in building construction, building material processing, construction, etc., can solve problems affecting building waterproof, rainproof performance, living and use, building roof distortion, and large roof joints. , to achieve the effect of simple and fast construction, high straightness, and improved waterproof level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention is further described below, but the scope of protection is not limited to the above.

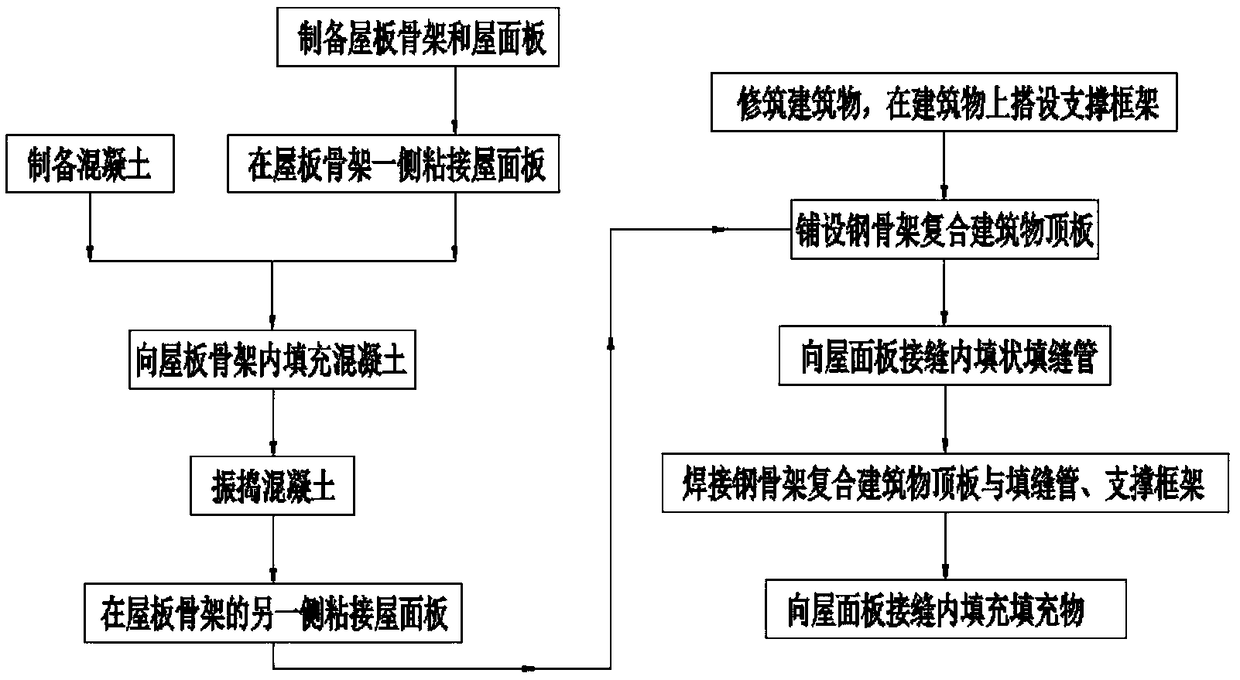

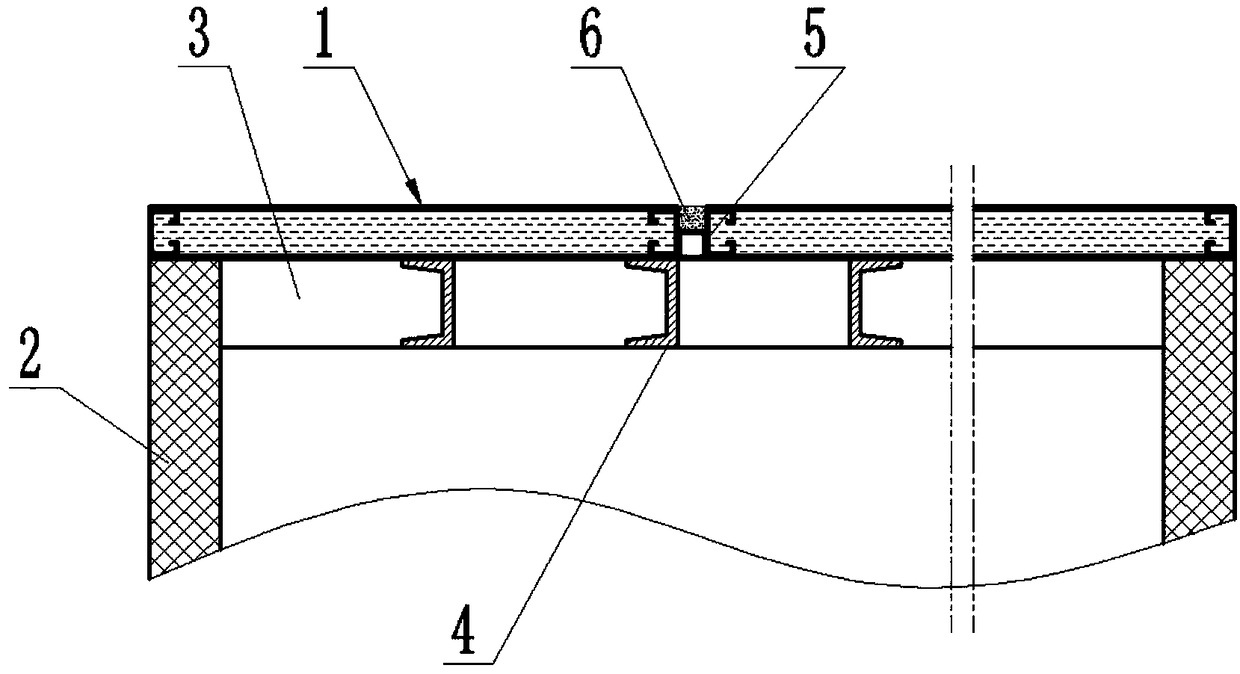

[0030] Such as figure 1 , figure 2 , image 3 As shown, the present invention provides a construction process for laying the roof of a steel frame composite building, which includes the following steps:

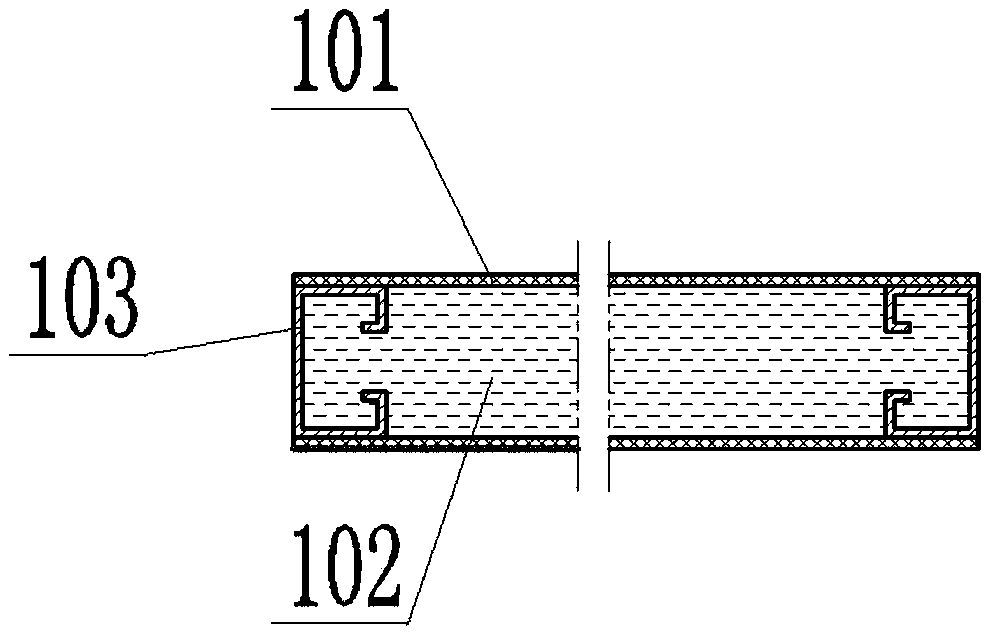

[0031] Step 1: Prepare roof frame 103 and roof panel 101: Use multiple C-shaped steels to be welded together end to end to form a square roof frame 103. Use a cutting machine to cut out a number of square roof panels 101, outside of the roof frame 103 The edge contour is consistent with the shape and size of the roof panel 101; further, the material of the roof panel 101 is a modified cement perlite composite core material.

[0032] Step 2: Apply adhesive along the edge of the roof panel 101 in Step 1, and bond the roof frame 103 to the roof panel 101;

[0033] Step 3: Prepare concrete 102: Put an appropriate amount of cement, stones, sand, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap