Vacuum high-low temperature composite loading device

A composite loading, high and low temperature technology, used in measuring devices, testing of machine/structural components, testing of mechanical components, etc., to achieve the effect of reducing usage requirements, reducing friction torque, and avoiding adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

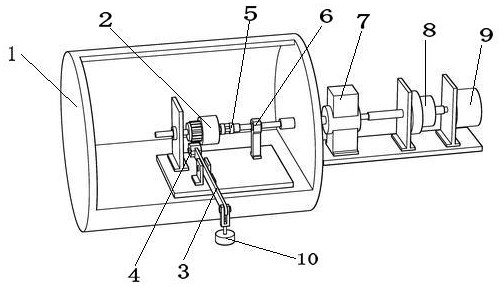

[0022] refer to figure 1 with figure 2 As shown, a vacuum high and low temperature composite loading device includes a vacuum high and low temperature ring mold equipment 1, a driving mechanism 2, a loading lever 3, a bearing assembly 4, a coupling 5, an adapter support seat 6, a moment sensor 7, and an inertial load 8 and magnetic powder brake 9;

[0023] In the vacuum high and low temperature ring mold equipment 1, the driving mechanism 2 is installed on the bottom plate of the vacuum high and low temperature ring mold equipment 1 through a bracket. It is fixed on the same bottom plate as the driving mechanism 2, and the adapter shaft is connected with the magnetic fluid seal shaft on the vacuum high and low temperature ring mold equipment 1;

[0024] The end of the loading lever 3 hangs a weight 10, and the loading lever 3 converts the gravity of the weight 10 into a radial force and applies it to the driving mechanism 2 through a pair of bearing assemblies;

[0025] The t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap