Testing device for fatigue life of steel hole belt

A test device and fatigue life technology, applied in the field of mechanical engineering, can solve the problems that test equipment is difficult to apply to steel perforated belts, etc., and achieve the effects of easy inspection and maintenance, convenient disassembly, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

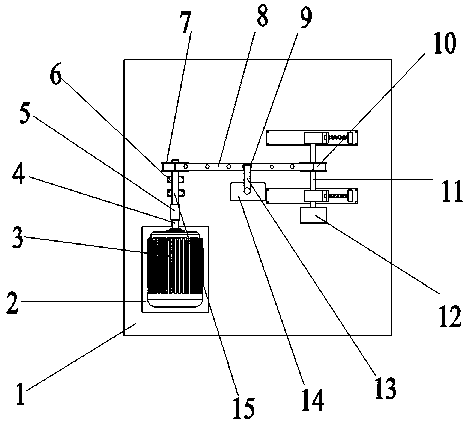

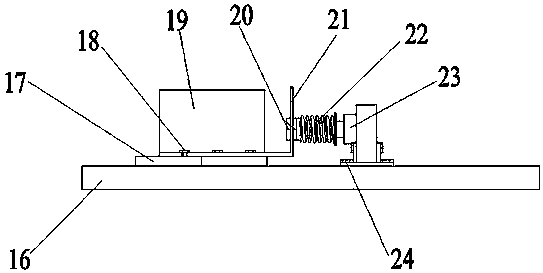

[0019] Specific embodiments are given below in conjunction with the drawings. An embodiment of the present invention is to test the fatigue life of the steel hole belt under set load conditions. As shown in the figure, install the steel hole belt (8) on the driving wheel (7) and the driven wheel (10) , Turn the adjusting bolt (20), move the track slider (17) to drive the sliding bearing seat (19) to slide until the steel hole belt (8) is in tension, and tighten the adjusting bolt (20) to make the sliding bearing seat ( 19) Fix, turn on the magnetic powder brake (12), adjust the braking force to the set value, turn on the power of the counting sensor (13), and finally turn on the power of the motor (3) to rotate at the set speed, and then drive the steel The hole-making belt (8) rotates, and the counting sensor (13) starts counting until the steel hole-making belt (8) is broken, and the entire test work is completed.

[0020] The present invention can change the diameter of the driv

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap