Fatigue testing device for swing rotating shaft

A technology of fatigue testing and rotating shafts, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of difficult to control the amplitude of swing, low efficiency, time consumption, etc., and achieve accurate feedback adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

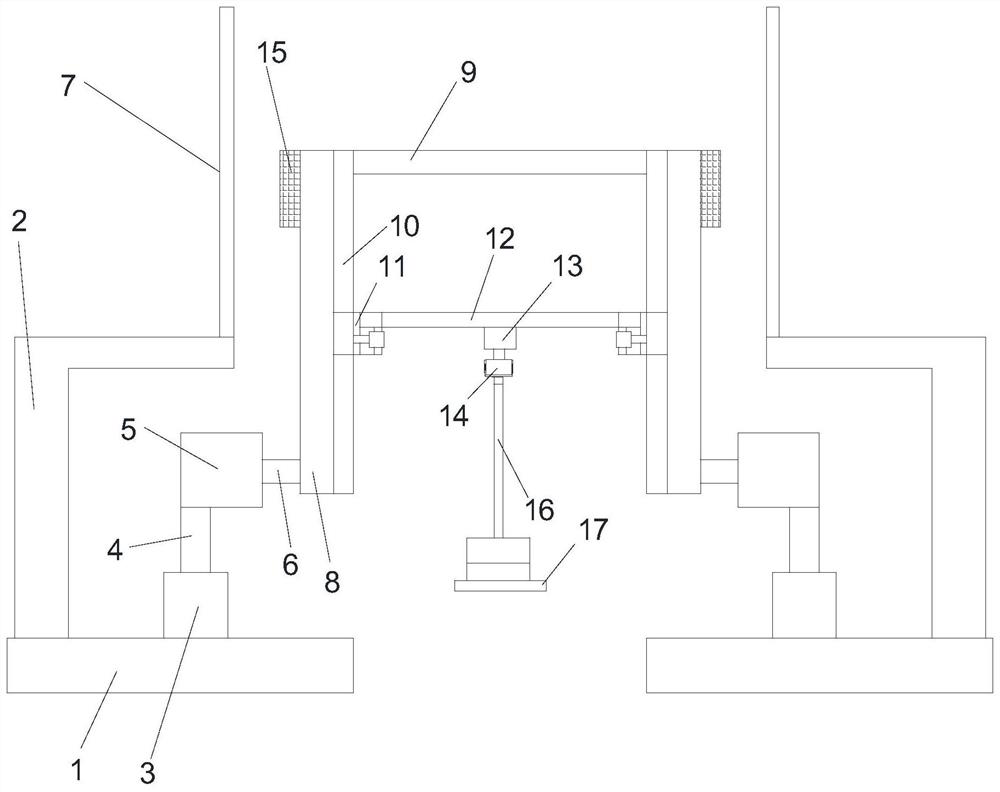

[0038] The fatigue test device used for the swing shaft in the present invention includes a base 1, a frame body 2, an angle plate 7, a height adjustment unit 3, a swing motor 5, an eccentric rod 8, a guide rod 10, a sliding unit 11, and a second connecting rod 12 , shaft connection unit 13 and load assembly, see figure 1 .

[0039] There are two bases 1 arranged symmetrically, so all components in the technical solution are arranged symmetrically. The frame body 2 is arranged on the base 1 , and the frame body is mainly provided for placing the angle plate 7 . The angle plate 7 is vertically arranged on the frame body 2, and an angle scale of 0-180 degrees is marked on the angle plate.

[0040] The height adjustment unit 3 is arranged on the base 1, and the height adjustment push shaft 4 of the height adjustment unit 3 is vertically upward; the swing motor 5 is arranged on the height adjustment push shaft 4, and the swing output shaft 6 of the swing motor 5 is Horizontal ori

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap