Walking beam type pumping unit working system combined operation method

A technology of beam pumping unit and working system, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., which can solve the problems of low motor drive efficiency, high plunger leakage rate, single well production and oil-producing layer development Unfavorable effects and other problems, to meet the needs of safety warnings, solve the high leakage rate of the plunger, and eliminate the need for start-up operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0027] The combined operation method of the working system of the beam pumping unit in this embodiment,

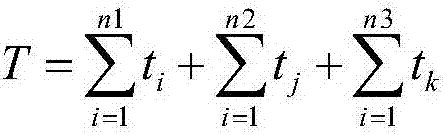

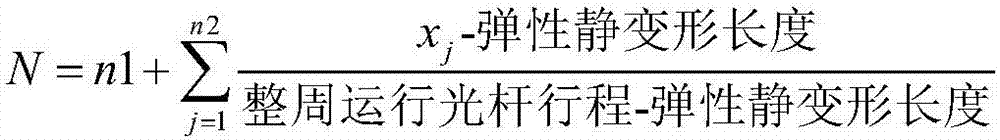

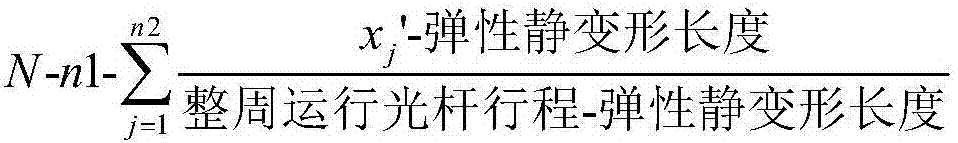

[0028] According to the theoretical round number N in the period T, the following conditions are met:

[0029]

[0030]

[0031] Assign the number of times n1 of the crank to run in a full cycle, and the time t for each full cycle 1 , t 2 ,...,t n1 ;The number of pumping operations n2 of the crank part-cycle, and the stroke of the polished rod x in each part-cycle part of the pumping operation 1 、x 2 ,...,x n2 , each part-week has a swabbing run time t 1 , t 2 ,...,t n2 ;Crank non-full cycle without swabbing operation times n3, each partial cycle with swabbing time t 1 , t 2 ,...,t n3 ; and the sequence of the crank full circle running, the crank part full circle with swabbing operation, and the crank part part full circle without swabbing.

[0032] This embodiment also has the following three points to be explained:

[0033] First, the concept of cycle in t

specific Embodiment 2

[0036] The working system combination operation method of the beam pumping unit in this embodiment, on the basis of the specific embodiment 1, further limits that the duration of the non-full cycle of the crank without swabbing does not exceed the threshold value of the sedimentation time, the threshold value of the waxing time, the freezing time The minimum value of the blocking time threshold and stratification time threshold.

[0037] If there is no pumping for a long time during operation, problems of sand settling, wax formation, freezing blockage, or stratification will occur. However, this technical solution limitation can effectively avoid the problems of sand settling, wax formation, freezing blockage, and stratification when the non-swabbing operation time is too long.

specific Embodiment 3

[0038] The working system combination operation method of the beam pumping unit in this embodiment, on the basis of the specific embodiment 1, further limits the duration of the non-full circle non-swabbing operation with a crank angle of less than 90 degrees to not exceed the requirements of the reducer gearbox Lubrication time threshold.

[0039] Since the gears in the gear box of the beam pumping unit reducer are arranged horizontally, if the crank swings at a rotation angle of less than 90 degrees during operation, there is a problem that the lubricating oil cannot lubricate the contact surfaces of the two gears. Swinging like this for a long time will affect the service life of the reducer gearbox. And this technical scheme is limited, can guarantee that gear is fully lubricated, prolongs the service life of gear box of pumping unit reducer.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap