Environmental-friendly water-resistance high-strength ceramic gum and preparation method

A high-strength, tile-based technology, applied in the field of tile adhesives, can solve problems such as environmental pollution, hollow tiles, and excessive powder waste, and achieve the effects of reducing costs, improving economic benefits, and reducing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

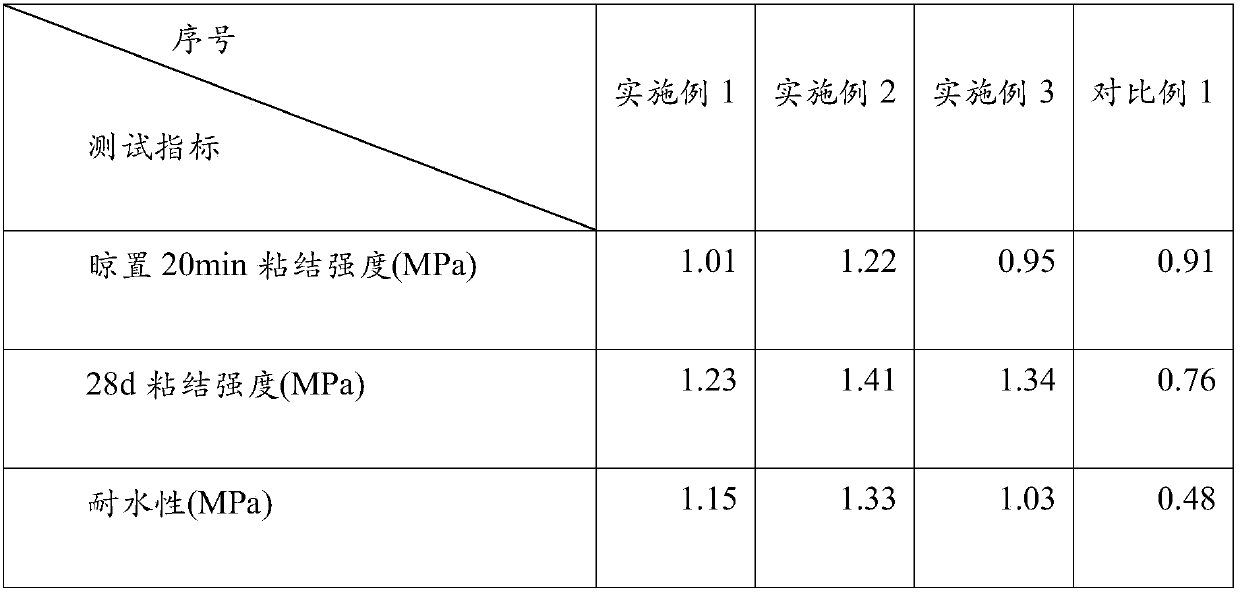

Examples

Embodiment 1

[0021] An environmentally friendly and water-resistant high-strength ceramic tile adhesive, comprising the following components by weight:

[0022] 30 parts of acrylic emulsion, 67.85 parts of artificial quartz stone powder, 2 parts of hydroxypropyl methylcellulose slurry, 0.15 parts of water reducing agent and 0.3% of preservative;

[0023] Wherein, the hydroxypropyl methylcellulose slurry is an aqueous solution of hydroxypropyl methylcellulose with a mass fraction of 1%. .

[0024] Wherein, the preservative is formed by mixing methylisothiazolone and preservative BIT20 in a mass ratio of 1:1.

[0025] Wherein, in the above-mentioned environmentally friendly and water-resistant high-strength tile adhesive, the solid content of the acrylic acid is greater than 50%.

[0026] Wherein, in the above-mentioned environmental protection and water-resistant high-strength tile adhesive, the fineness of the artificial quartz stone powder is 30 μm.

[0027] Wherein, in the above-mentione

Embodiment 2

[0035] An environmentally friendly and water-resistant high-strength ceramic tile adhesive, comprising the following components by weight:

[0036] 35 parts of acrylic emulsion, 62.4 parts of artificial quartz stone powder, 2.5 parts of hydroxypropyl methylcellulose slurry, 0.1 part of water reducing agent and 0.3% of preservative;

[0037] Wherein, the hydroxypropyl methylcellulose slurry is an aqueous solution of hydroxypropyl methylcellulose with a mass fraction of 1%. .

[0038] Wherein, the preservative is formed by mixing methylisothiazolone and preservative BIT20 in a mass ratio of 1:1.

[0039] Wherein, in the above-mentioned environmentally friendly and water-resistant high-strength tile adhesive, the solid content of the acrylic acid is greater than 50%.

[0040] Wherein, in the above-mentioned environmentally friendly and water-resistant high-strength tile adhesive, the fineness of the artificial quartz stone powder is 50 μm.

[0041] Wherein, in the above-mentioned

Embodiment 3

[0049] An environmentally friendly and water-resistant high-strength ceramic tile adhesive, comprising the following components by weight:

[0050] 40 parts of acrylic emulsion, 56.95 parts of artificial quartz stone powder, 3 parts of hydroxypropyl methylcellulose slurry, 0.05 parts of water reducing agent and 0.3% of preservative;

[0051] Wherein, the hydroxypropyl methylcellulose slurry is an aqueous solution of hydroxypropyl methylcellulose with a mass fraction of 1%. .

[0052] Wherein, the preservative is formed by mixing methylisothiazolone and preservative BIT20 in a mass ratio of 1:1.

[0053] Wherein, in the above-mentioned environmentally friendly and water-resistant high-strength tile adhesive, the solid content of the acrylic acid is greater than 50%.

[0054] Wherein, in the above-mentioned environmentally friendly and water-resistant high-strength tile adhesive, the fineness of the artificial quartz stone powder is 60 μm.

[0055] Wherein, in the above-mentione

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap