Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7 results about "Superplasticizer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Superplasticizers (SP's), also known as high range water reducers, are additives used in making high strength concrete. Plasticers are chemical compounds that enable the production of concrete with ca. 15% less water content. Superplasticers allow reduction in water content by 30% or more. These additives are employed at the level of a few weight percent. Plasticizers and superplasticizers retard the curing of concrete.

C50 high performance concrete prepared from fully-recycled fine aggregate

Owner:SOUTH CHINA UNIV OF TECH

Coating material for sealing coal wall of gob-side coal roadway

Owner:SHANDONG UNIV OF SCI & TECH

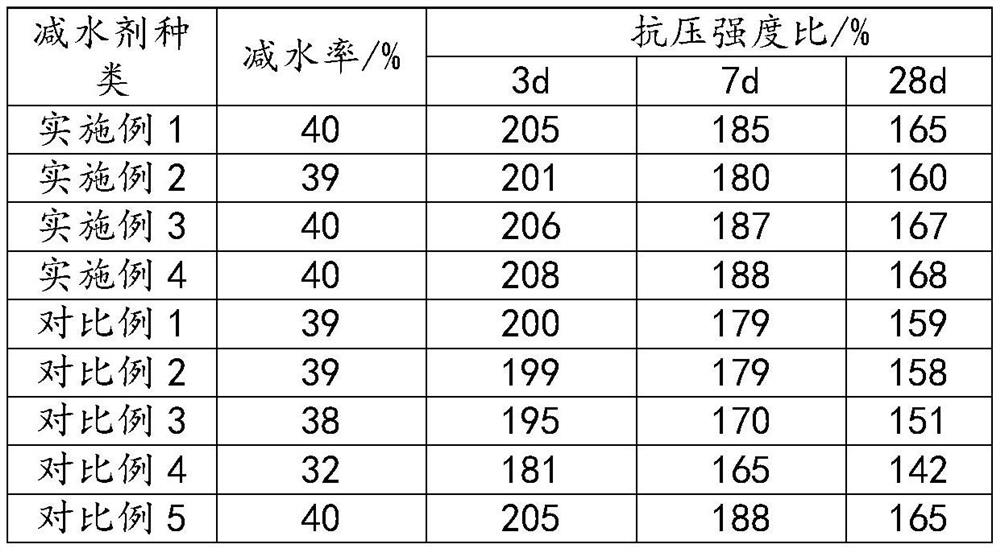

Concrete high-efficiency water reducer and preparation method thereof

Owner:KUNMING ANXIA NEW MATERIAL SCI & TECH CO LTD

Cement additive

The invention discloses a cement additive. The cement additive is prepared from the following raw materials in parts by weight: 20-35 parts of triisopropanolamine, 2-10 parts of triethanolamine, 10-25 parts of dispersible polymer, 2-8 parts of polycarboxylate superplasticizer, 1-7 parts of chemical short fibers, 8-15 parts of bentonite, 1-5 parts of sodium polyacrylate and 1-5 parts of enhancer. The cement additive is compounded by use of inorganic matters and organic matters, and is non-toxic and odorless; the cement additive is capable of improving the fluidity of the cement, improving the grinding efficiency of a grinder and reducing the phenomenon of over-grinding of the cement, and therefore, the cement quality can be improved and the cost can be relatively low.

Owner:马健

Method for preparing modified naphthalene-based superplasticizer from heavy fraction obtained in production process of ethyl alcohol

Owner:萧县沃德化工科技有限公司 +1

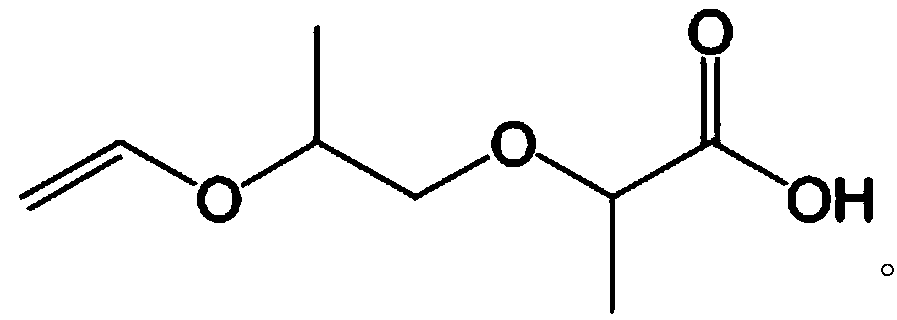

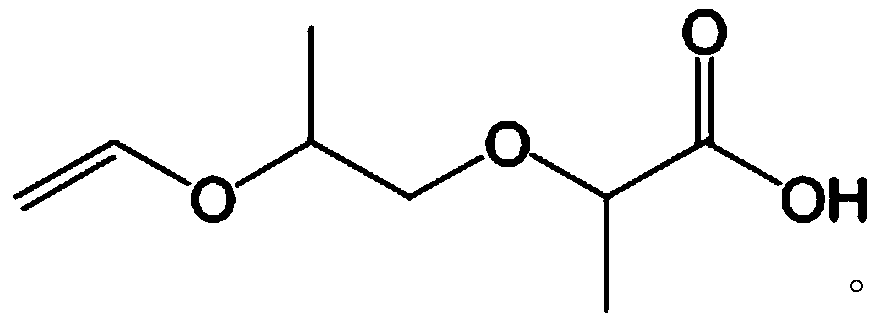

Mud-resistant early-strength enhanced polycarboxylate superplasticizer and preparation method thereof

Owner:安徽海螺材料科技股份有限公司 +1

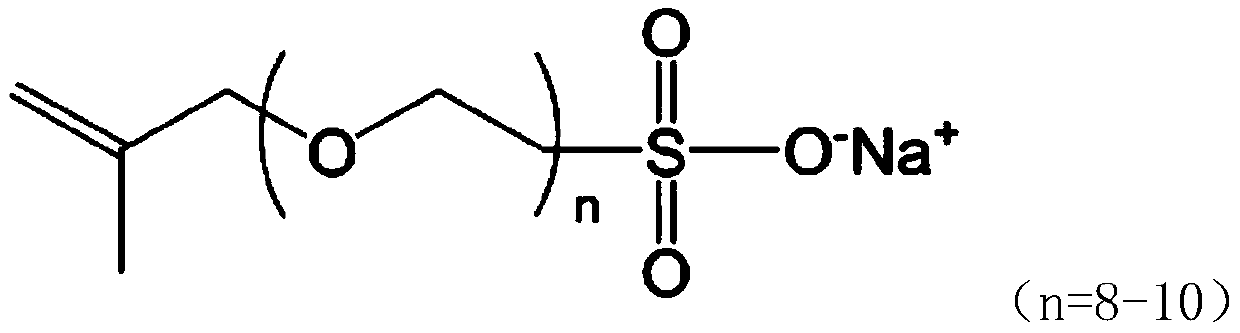

Esterification product for preparing water reducing agent, preparation method of esterification product, high-workability polycarboxylic acid water reducing agent and preparation method of high-workability polycarboxylic acid water reducing agent

PendingCN114181086AThere is no problem of uneven distributionExcellent high temperature corrosion resistanceOrganic compound preparationCarboxylic acid esters preparationSuperplasticizerBackbone chain

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap