Laser acceleration proton beam homogenization method and device

A proton beam and homogenization technology, applied in accelerators, electrical components, etc., can solve the problem of low current intensity of proton beams and achieve the effect of uniformity optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0041] Below in conjunction with the accompanying drawings, the present invention will be further described through specific embodiments.

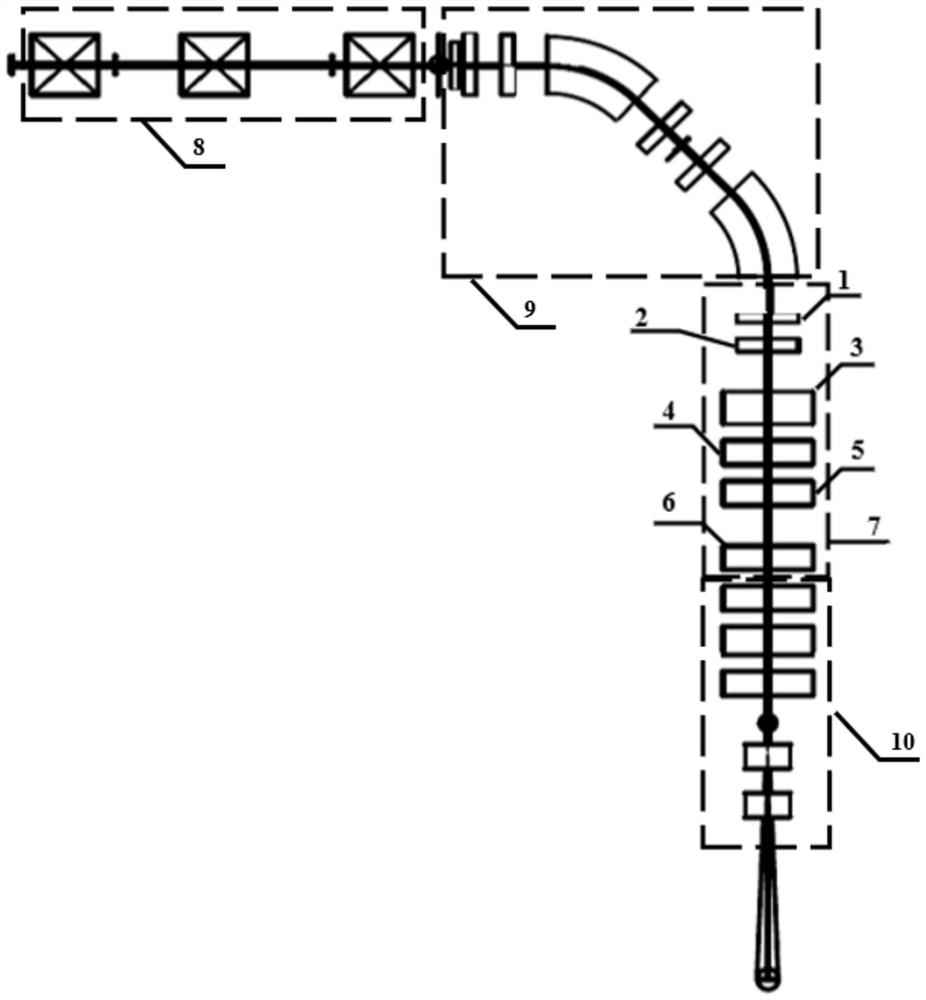

[0042] like figure 1 As shown, the laser accelerated proton beam homogenization system based on nonlinear high-order magnets in this embodiment includes: a beam collection section 8, an energy selection section 9, a beam homogenization transmission line 7 and a beam shaping transmission line 10; The beam of ideal energy passes through the beam collection section and the energy selection section to obtain the proton beam of ideal energy; the lateral distribution of the proton beam of ideal energy is Gaussian distribution, and the ideal energy particles pass through the beam homogenization transmission line to complete the uniform distribution of the beam. Finally, through the beam shaping transmission line, a uniform proton beam with a rectangular cross-section is obtained, which is used for the later step scanning treatment of cancer; wherein

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap