Bucket and hammer quickly-replacing device

A fast, hydraulic breaker technology, applied in the direction of mechanically driven excavators/dredgers, etc., can solve problems such as long time-consuming and affecting construction efficiency, reduce construction equipment investment, improve tunneling construction efficiency, and shorten replacement time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

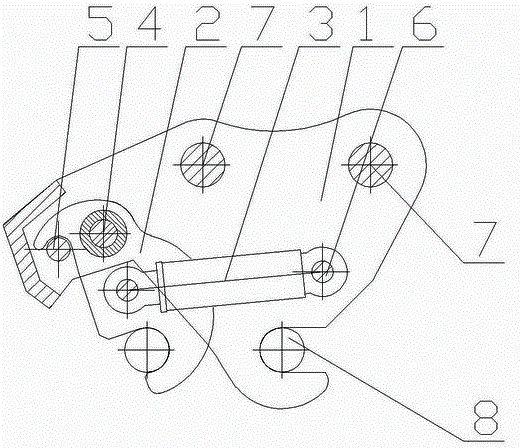

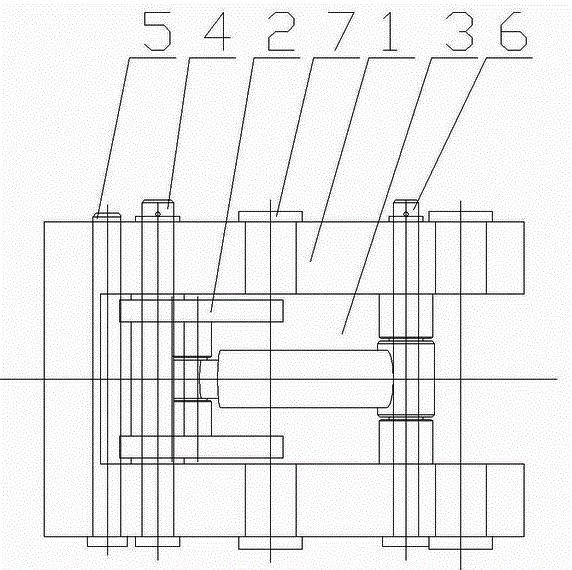

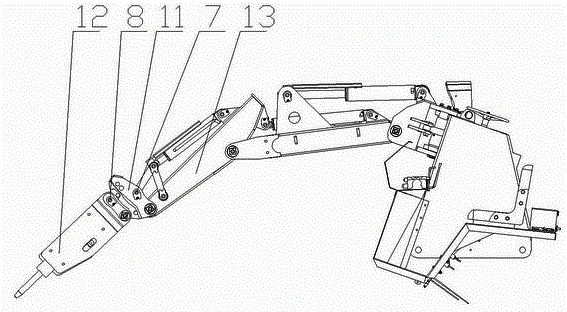

[0019] Such as figure 1 , figure 2 As shown, the bucket and hammer quick-change device of the present invention is composed of a fixed hook 1, a movable hook 2, a clamping oil cylinder 3, a rotating shaft 4, a limit pin 5, a connecting pin 6, and a hydraulic control system thereof.

[0020] The movable hook body 2 is placed in the neutral gear of the fixed hook body 1, and is hinged with the fixed hook body 1 through the rotating shaft 4, and can rotate around the rotating shaft 4. One end of the clamping oil cylinder 3 is hinged with the fixed hook body 1 through the connecting pin 6, and the other end is hinged with the movable hook body 2 through the connecting pin 6. The clamping cylinder 3 and its connecting pins 6 at both ends, the fixed hook 1 and the movable hook 2 together form a quick clamping mechanism. By pushing and pulling the fixed hook 1, the movable hook 2 and their clamping hooks, the clamping hook can be loosened. And the two connecting shafts 8 on the clamp

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap