A hydraulic system and a method for moving an implement of a working machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

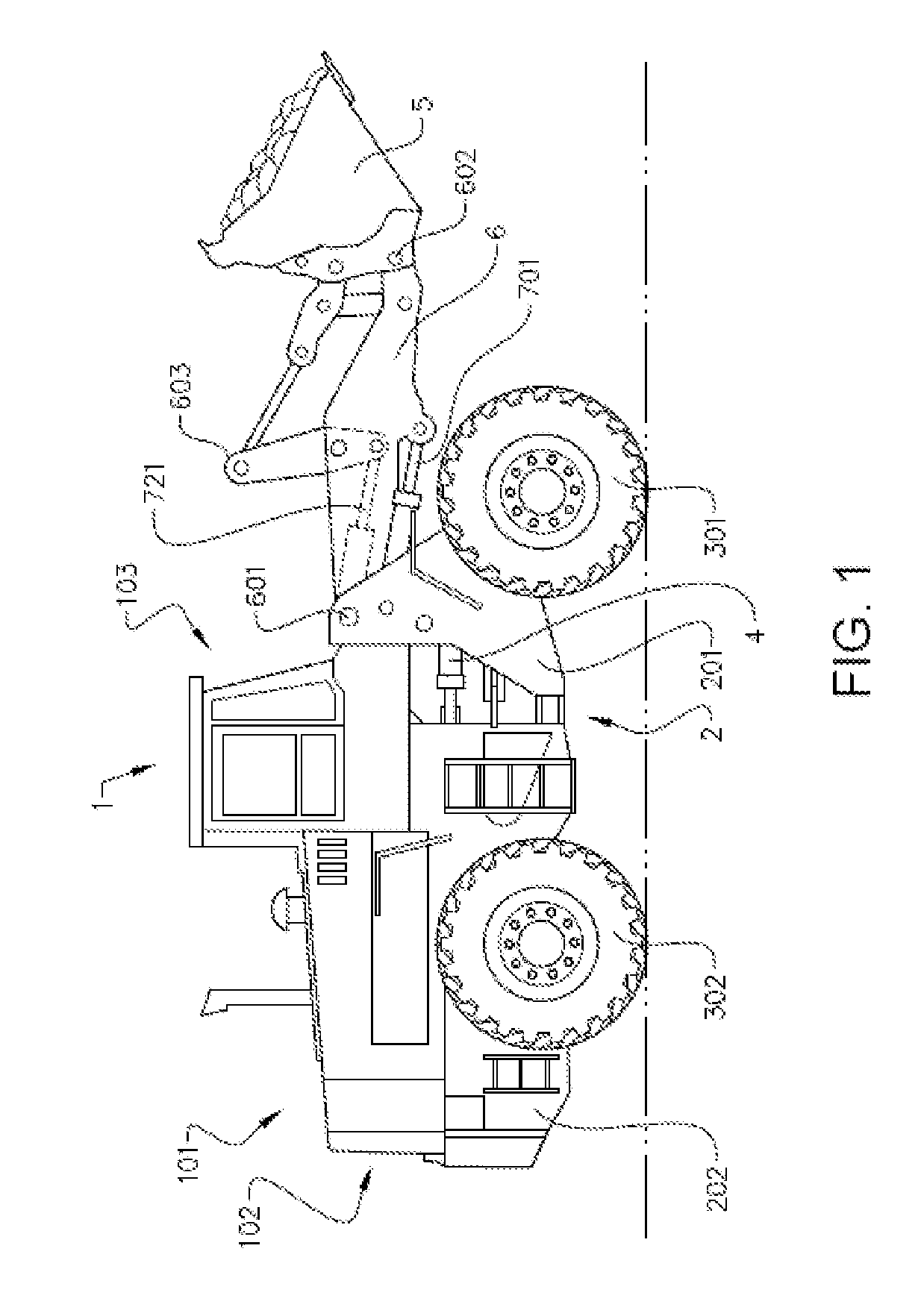

[0073]FIG. 1 is an illustration of a working machine 1 in the form of a wheel loader. The wheel loader is an example of a working machine where a hydraulic system according to the invention can be applied.

[0074]The wheel loader comprises a body structure 2 with a front body part 201 and a rear body part 202 presenting two front wheels 301 and two rear wheels 302, respectively. Two steering hydraulic cylinders 4 are arranged on opposite sides of the wheel loader 1 for turning the wheel loader by means of relative movement of the front body part 201 and the rear body part 202. In other words, the wheel loader 1 is articulated and frame steered by means of the steering hydraulic cylinders 4. There is a pivot joint connecting the front body part 201 and the rear body part 202 of the wheel loader 1 such that these parts are pivotally connected to each other for pivoting about a substantially vertical axis.

[0075]The rear body part 202 of the wheel loader 1 comprises an engine compartment 101

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap