Base of Y-series three-phase asynchronous motor

A three-phase asynchronous motor technology, applied in the direction of asynchronous induction motors, electric components, electrical components, etc., can solve the problems of increased manufacturing costs, bloated motor structure, large volume, etc., to achieve reduced volume and weight, compact and beautiful appearance, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

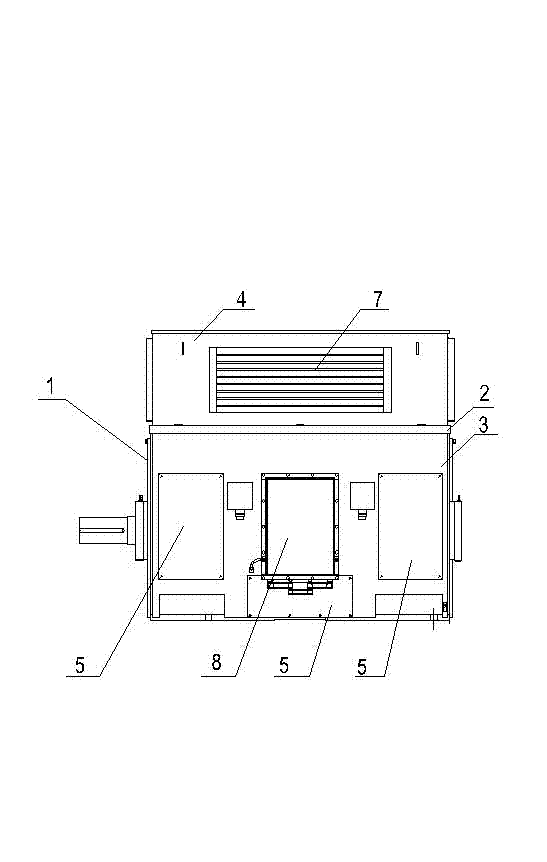

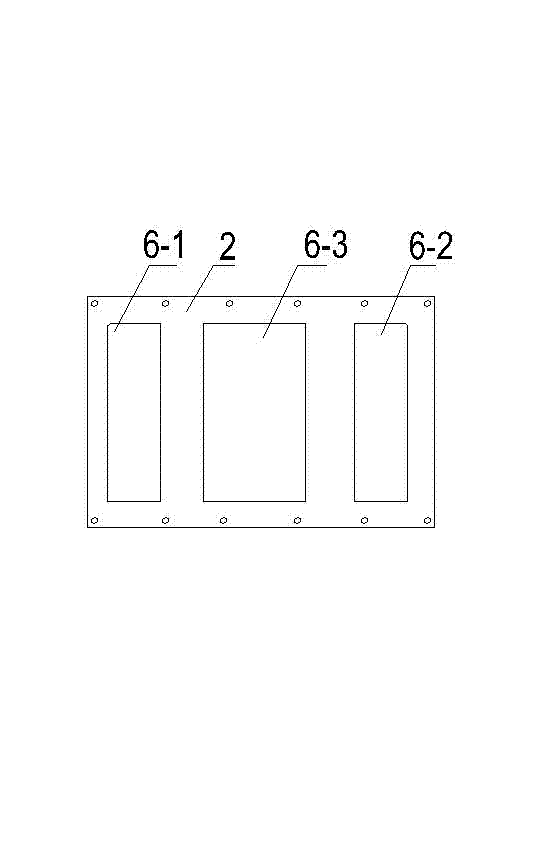

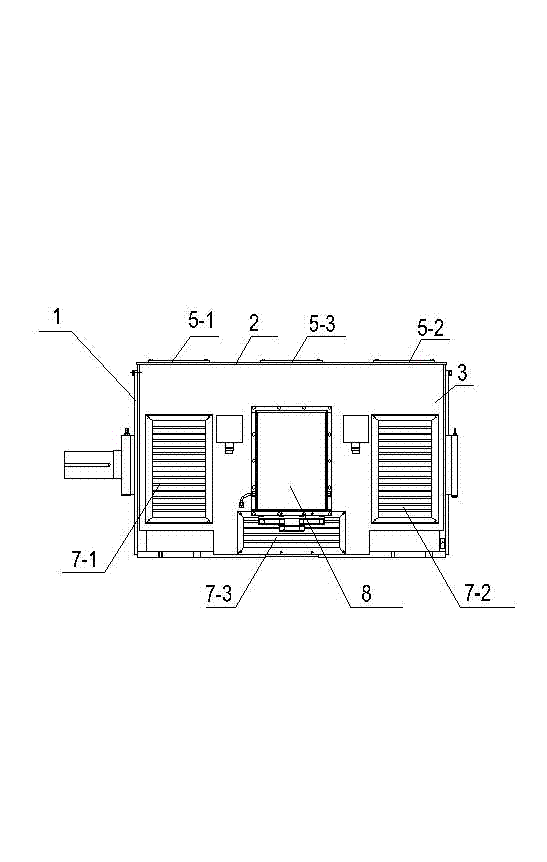

[0022] Such as image 3 As shown, the base of the Y series three-phase asynchronous motor includes the base body 1, and the base body 1 includes the upper top plate 2 and the side plates 3 on both sides. Louvers (construction shown with side panels on one side of the junction box).

[0023] Such as image 3 As shown, the air intake louvers on each side plate are divided into a first air intake louver 7-1 and a second air intake louver 7-2, and the two air intake louvers are close to the two ends of the base body, and one side of the side plate Junction box 8 is installed between the two air-inlet shutters, and wind-out shutter 7-3 is installed in the bottom of junction box 8, and air-inlet shutter and air-out shutter are respectively connected through air inlet and air outlet and the inside of the base.

[0024] Such as image 3 As shown, the base to

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap