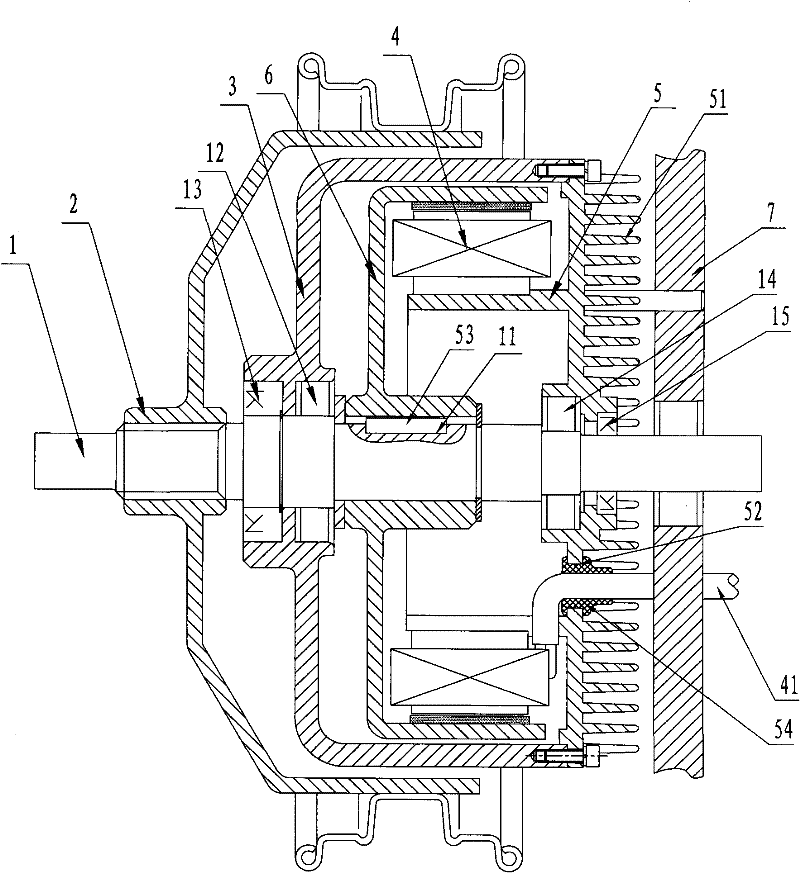

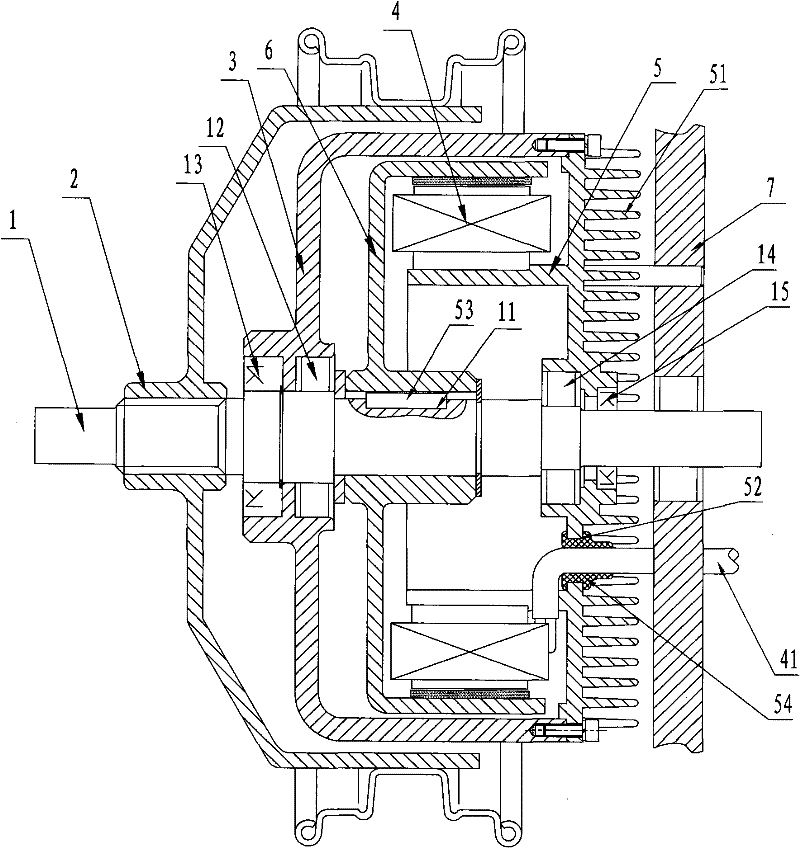

Structure for motor of electric vehicle

A motor structure, electric vehicle technology, applied in electric vehicles, motors, electric components, etc., can solve problems such as unsatisfactory sealing effect, low connection reliability, and motor temperature rise, and achieve lower temperature, faster heat dissipation, and stable connection. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

[0014] Embodiment: An electric vehicle motor structure, including a shaft 1, a transmission disc 2, a casing 3, a stator core coil winding 4, a bracket plate 5 and a rotor 6, the transmission disc 2 is fixedly sleeved on the outer circumference of one end of the shaft 1, and the casing 3 One end of the dynamic seal is rotatably sleeved on the outer circumference of one end of the shaft, the rotor 6 is fixedly sleeved on the shaft, the stator core coil winding 4 is located inside the inner circumferential surface of the rotor 6, the stator core coil winding 4 is fixed on the bracket plate 5, and the bracket The inner dynamic sealing rotation of the plate 5 in the circumferential direction is sleeved on the shaft 1, and the outer end of the support plate 5 in the circumferential direction is sealed and fixed with the other end of the casing 3. The shaft 1, the support plate 5 and the casing 3 together form an annular sealed space, and the rotor 6 and stator core coil windings are al

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap