Base unit, motor, and air blowing device

a technology of air blowing device and base unit, which is applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of decreasing and achieve the effect of reducing the reliability of the base uni

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

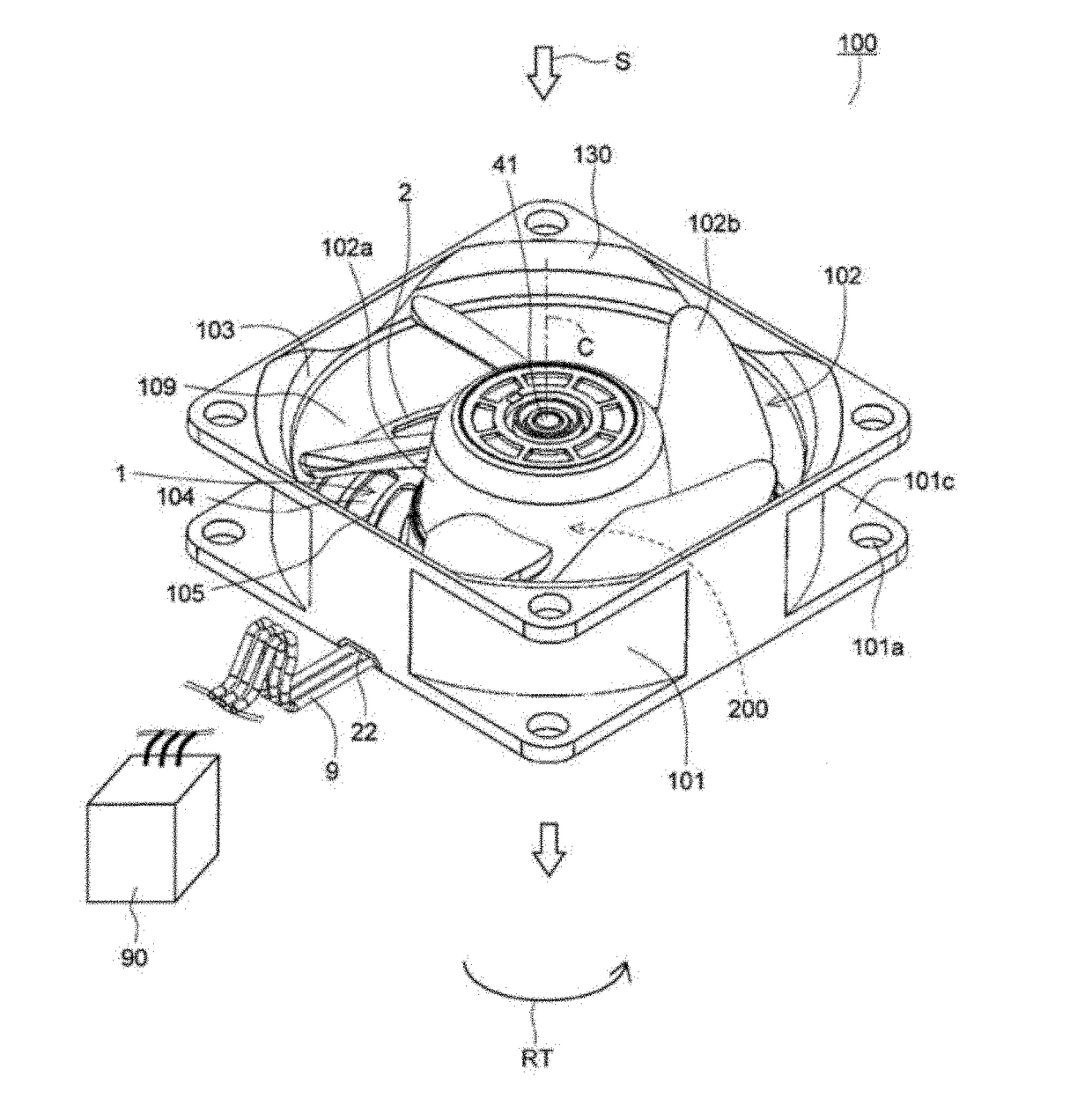

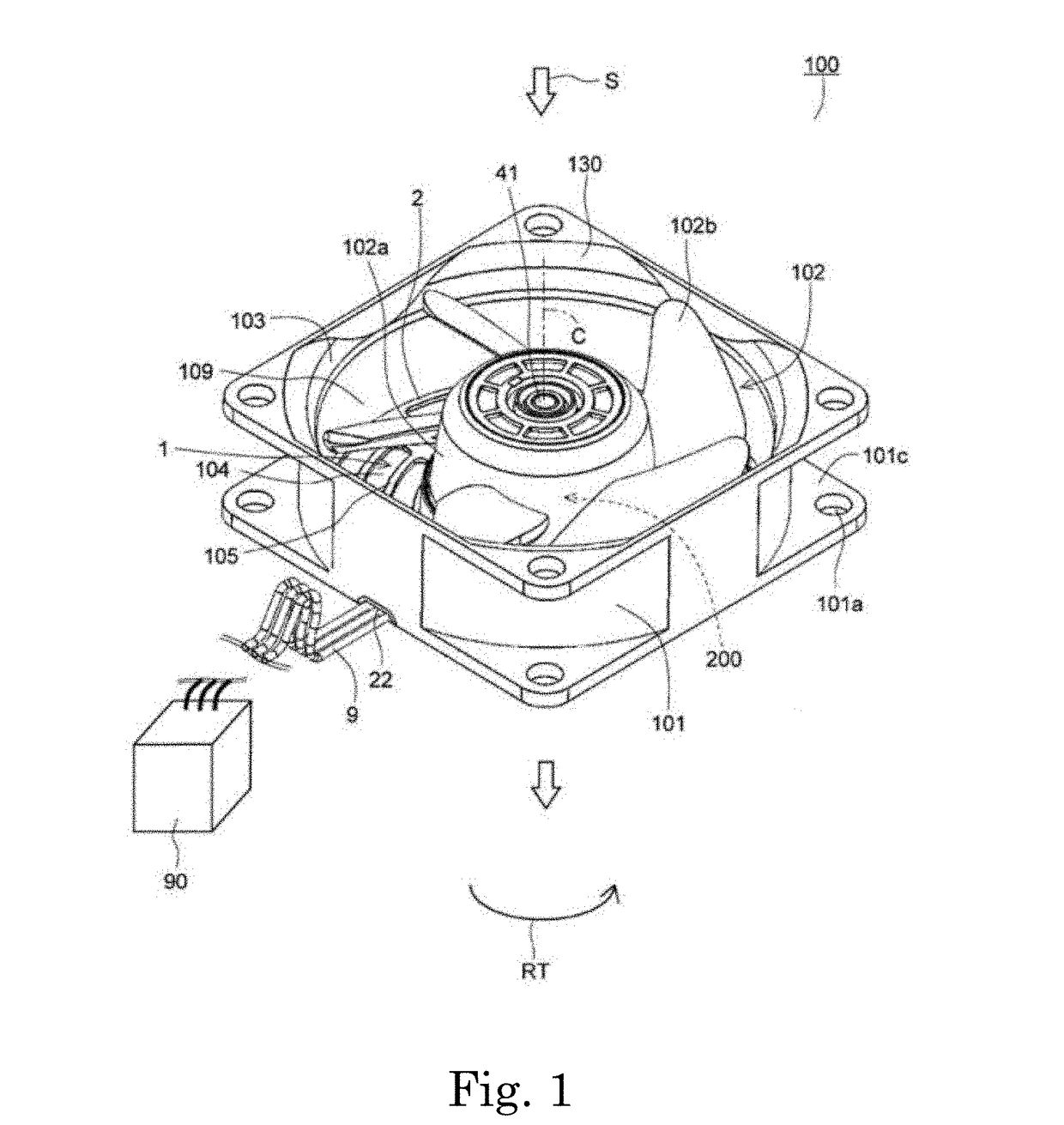

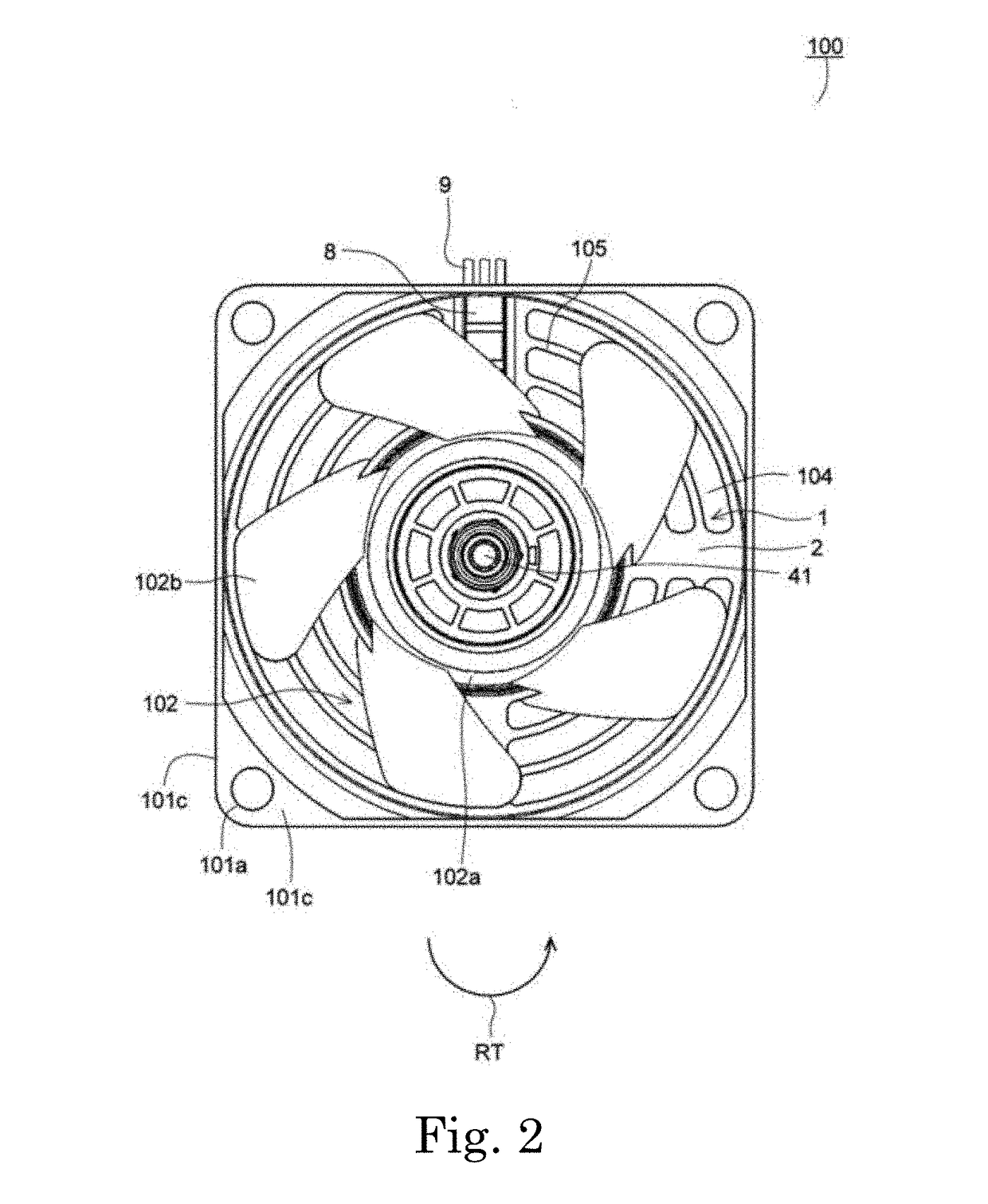

[0039]Hereinafter, exemplary embodiments of the disclosure will be described in detail with reference to drawings. Note that, in the specification, with regard to a base unit 1, a motor 200, and an air blowing device 100, a direction parallel to a central axis C of the base unit 1 will be referred to as an “axial direction”, a direction orthogonal to the central axis C of the base unit 1 will be referred to as a “radial direction”, and a direction along an arc around the central axis C of the base unit 1 will be referred to as a “circumferential direction”.

[0040]Similarly, with regard to an impeller 102, directions that coincide with the axial direction, the radial direction, and the circumferential direction of the air blowing device 100 in a state where the impeller 102 is incorporated in the air blowing device 100 will be simply referred to as an “axial direction”, a “radial direction”, and a “circumferential direction”. In addition, in the specification, the shape of each portion a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap