Cooling system for drive motor in twin-screw extruder

A twin-screw extruder and drive motor technology, applied in the direction of electromechanical devices, cooling/ventilation devices, electrical components, etc., can solve the problems of reducing the service life of the drive motor, small cooling holes, high temperature of the drive motor, etc., to ensure the service life , Effective cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

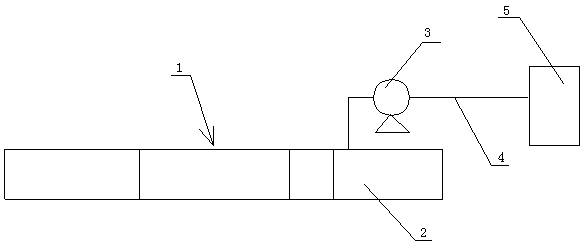

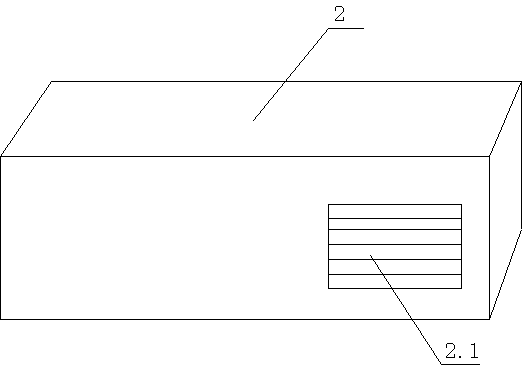

[0011] see figure 1 , the present invention relates to a cooling system for a drive motor in a twin-screw extruder, comprising a drive motor case 2, cooling holes 2.1, an air pump 3 and an air intake pipe 4, the drive motor case 2 is installed in a twin-screw extruder The front end of the machine 1, the side wall of the drive motor box 2 is provided with cooling holes 2.1, the top of the drive motor box 2 is connected with an air pump 3, the air inlet of the air pump 3 and the air intake pipe 4, and the other end of the intake pipe 4 is connected to the cold air source 5.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap