A refrigerant transmission sealing structure for superconducting motor

A technology of superconducting motors and sealing structures, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., to achieve the effects of reduced assembly difficulty, easy structure, and increased dynamic pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

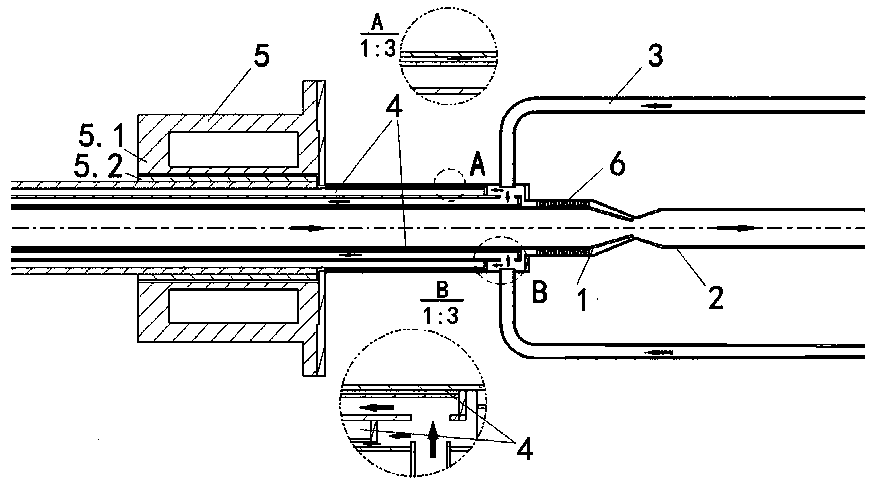

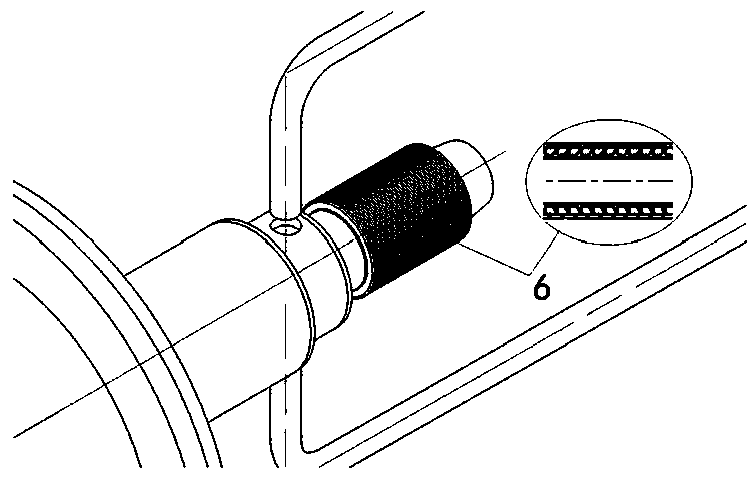

[0022] Such as figure 1 As shown, the refrigerant transmission sealing structure of the superconducting motor of the present invention includes a stationary intake pipe 1, a rotating intake pipe 2, a gas return pipe 3, a vacuum interlayer pipe 4, a magnetic fluid sealing device 5 and a labyrinth sealing structure 6. The magnetic fluid sealing The device 5 comprises a rotating part 5.1 and a stationary part 5.2. The refrigerant gas enters the rotating inlet pipe 2 from the cryogenic refrigerator through the static inlet pipe 1 and then passes into the superconducting motor to cool the superconducting magnet. After the gas is heated, it returns to the refrigerator through the return pipe 3 and other circuits for cooling. The return air temperature is higher than the intake air temperature. In order to avoid energy loss, the vacuum interlayer pipe 4 is used to ins

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap