Automobile electronic water pump

A technology of automotive electronics and water pumps, which is applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of insufficient service life of electronic water pumps, low working efficiency, and large damage to water pumps, so as to improve heating effect and work efficiency , Improve the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

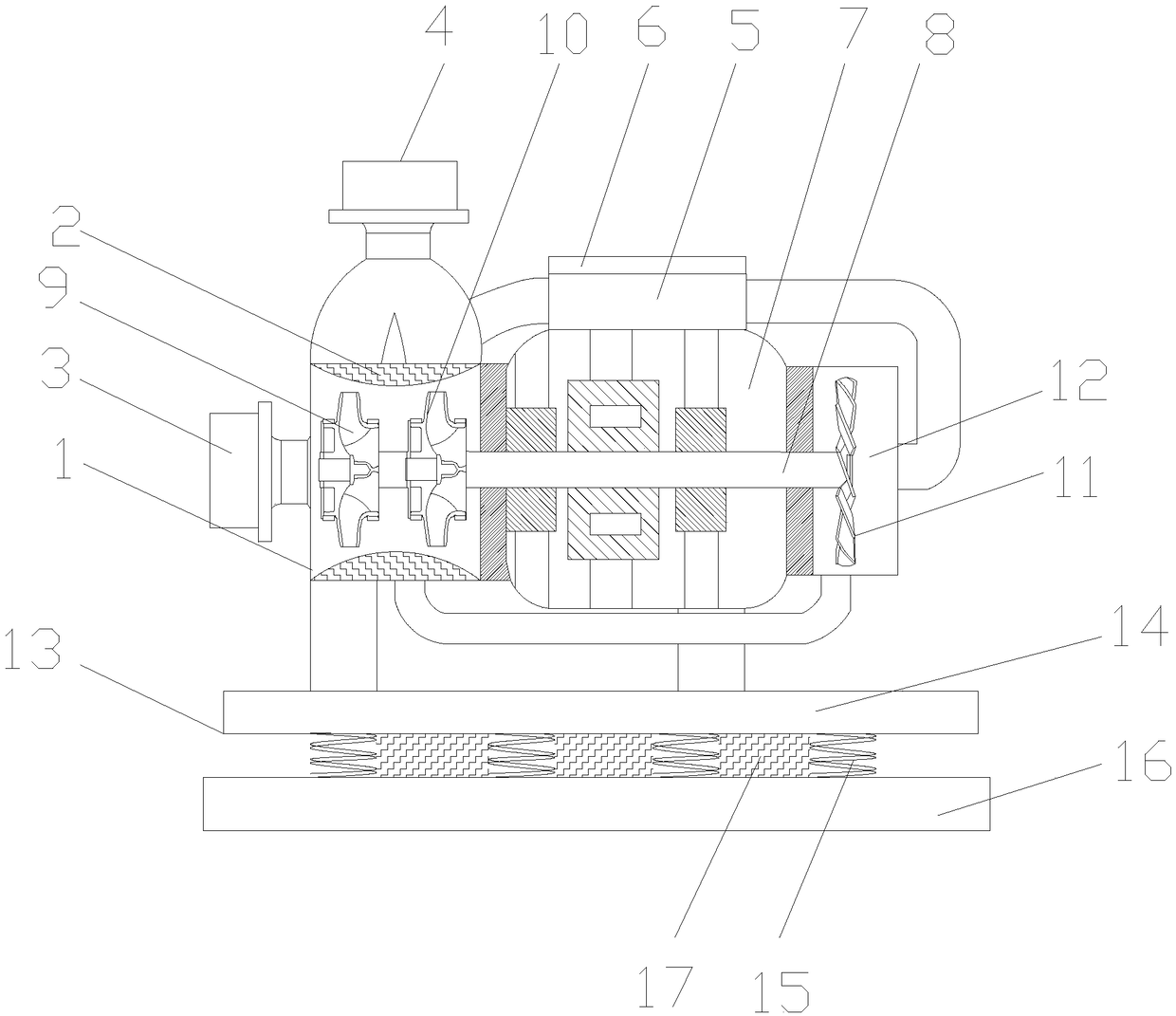

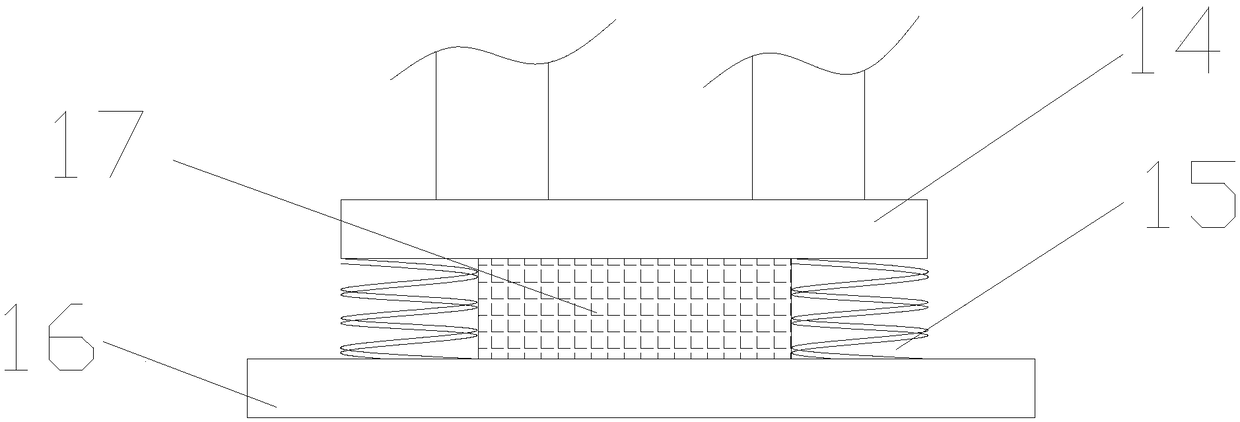

[0018] refer to Figure 1 to Figure 3 , an automotive electronic water pump, comprising a pump cover 1, an arc-shaped sponge layer 2, a water inlet 3, a water outlet 4, an arc-shaped transfer water tank 5, an electric control board 6, a motor 7, a rotating shaft 8, a first impeller 9, a second The impeller 10, the third impeller 11, the suction box 12 and the base 13, the two sides of the pump cover 1 are concave, the outer wall is covered with an arc-shaped sponge layer 2, one end is connected to the water inlet 3, and one side of the arc-shaped sponge layer 2 is connected to the water outlet 4. The water outlet 4 is Y-shaped. One side of the water outlet 4 is connected with a conduit, and the other end of the conduit is connected to the arc-shaped transfer water tank 5. The top of the arc-shaped transfer water tank 5 is equipped with an electric control board 6, and the bottom is attached to the outer wall of the motor 7. The motor 7. There is a rotating shaft 8 in the center.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap