Concrete mixing and transporting vehicle motor

A technology for mixing and conveying vehicles and concrete, which is applied in the direction of collectors, electromechanical devices, electric vehicles, etc., can solve the problem of generating a large amount of exhaust gas, and achieve the effect of improving power density, improving safety and stability, and avoiding the phenomenon of vehicle runaway.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

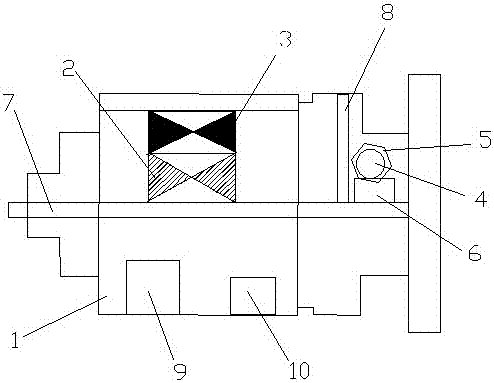

[0018] A concrete mixer truck motor, including a housing 1, a stator 2, a rotor 3, a fan 4, a wind cover 5 and a battery 6, a rotating shaft 7 is arranged in the middle of the housing 1, and the stator 2 is arranged on the rotor 3 Outside, one end inside the housing 1 is provided with a partition 8, one side of the partition 8 is provided with the fan 4, and the other side of the partition 8 is provided with the stator 2 and the rotor 3. The windshield 5 is arranged on the outside of the fan 4, the battery 6 is arranged below the fan 4, and the outer wall of the casing 1 is radially distributed with heat dissipation ribs, and the heat dissipation ribs are arranged radially Distributed at intervals, the heat dissipation ribs are covered with an outer cover plate, the outer cover plate is provided with heat dissipation grooves and heat dissipation holes, the heat dissipation grooves are provided with heat dissipation fins, and the heat dissipation fins and the heat dissipation holes

Embodiment 2

[0021] A concrete mixer truck motor, including a housing 1, a stator 2, a rotor 3, a fan 4, a wind cover 5 and a battery 6, a rotating shaft 7 is arranged in the middle of the housing 1, and the stator 2 is arranged on the rotor 3 Outside, one end inside the housing 1 is provided with a partition 8, one side of the partition 8 is provided with the fan 4, and the other side of the partition 8 is provided with the stator 2 and the rotor 3. The windshield 5 is arranged on the outside of the fan 4, the battery 6 is arranged below the fan 4, and the outer wall of the housing 1 is radially distributed with cooling ribs, and the outer wall of the cooling rib is covered with a cover The outer cover plate is provided with heat dissipation grooves and heat dissipation holes, the heat dissipation grooves are provided with heat dissipation fins, and the heat dissipation fins and the heat dissipation holes are arranged in a dislocation manner.

[0022] The inside of the housing is also provid

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap