Ceramic support for pre-oxidating copper sheet

A ceramic bracket and pre-oxidation technology, applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problems affecting product surface grain roughness and appearance quality, chip welding and surface wire bonding The contact between the sheet and the conveyor belt will be oxidized, so as to achieve smooth flow, improve the surface grain state, and uniform roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

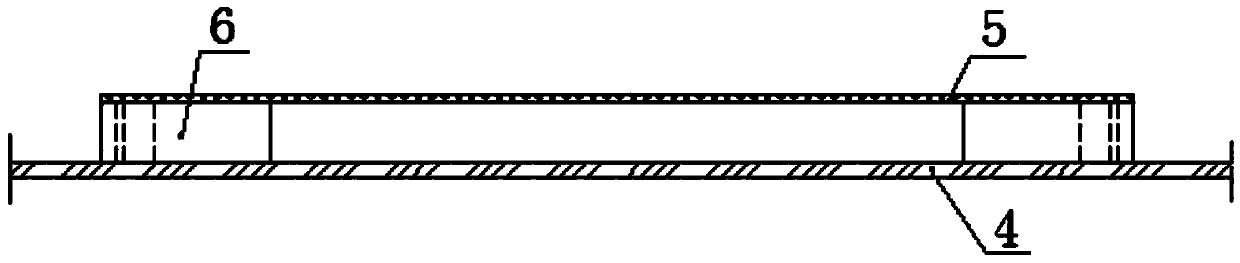

[0012] The ceramic support for copper pre-oxidation of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0013] like figure 1 As shown, the present invention is used for the ceramic support of pre-oxidation of copper sheet, at first use the ceramic substrate of 138 millimeters * 188 millimeters * 0.635 millimeters, cover the copper foil 3 of 0.1 millimeter ~ 0.4 millimeters on its surface. Patterns are etched out of ceramic substrates by pattern transfer and etching processes. Cut the ceramic substrate into individual long strips with a specific width using a laser cutter. Fold both ends of the strip-shaped ceramic substrate into 90 degrees along the center of the copper foil 3 to form a ceramic sheet body 1 and ceramic bending parts 2 arranged at both ends of the ceramic sheet body 1 .

[0014] like figure 2 As shown, two ceramic supports 6 are placed face to face on the conveyor belt 4, and then the copper sheet

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap