Printed circuit board and preparation method thereof

A technology for printed circuit boards and substrates, used in multilayer circuit manufacturing, printed circuit components, etc., can solve the problems of difficult to control impedance, uneven thickness of media, etc., to improve consistency, uniform thickness of media, and reduce expansion and contraction. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

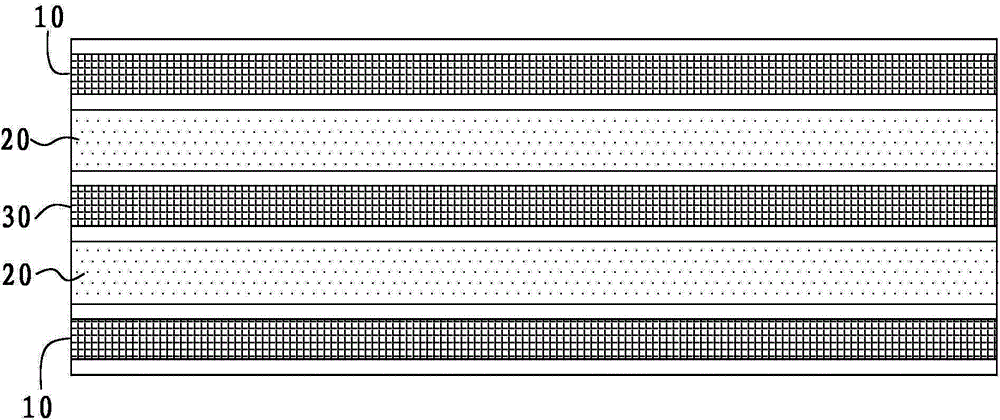

[0019] refer to figure 2 , a multilayer printed circuit board provided in this embodiment includes two outer layer boards 10, an inner layer board 30 and a prepreg 20 as a bonding material, and according to the outer layer board 10, the prepreg 20, the inner layer board 30, The prepreg 20 and the outer layer board 10 are laminated and bonded in sequence to form a six-layer printed circuit board. The inner board 30 is a substrate with inner circuit patterns on both surfaces; the outer board 10 is a substrate with inner circuit patterns on one surface and outer circuit patterns on the other surface. The side of the outer layer board 10 with the outer layer circuit pattern is used as the outer surface of the multilayer printed circuit board, that is, the surfaces of the two outer layer boards 10 with the inner layer circuit pattern face each other.

[0020] The preparation method of the multilayer printed circuit board of the present embodiment comprises the following steps:

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap