Catalyst for preparing low-carbon olefine by catalytic cracking using fluidized-bed and preparation method and use thereof

A technology of catalytic cracking and low-carbon olefins, which is applied in the preparation of the above-mentioned catalysts, the application of the above-mentioned catalysts, and the field of catalysts for the production of low-carbon olefins by fluidized bed catalytic cracking. It can solve the problems of insufficient research work and achieve coke yield. Low temperature, good hydrothermal stability, and high olefin yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of catalyst comprises the following steps:

[0047] The first step is the modification of the molecular sieve, that is, replacing the molecular sieve with a rare earth metal compound.

[0048] The second step is mixing and beating. Molecular sieve and non-stoichiometric aluminum phosphate are mixed with water for beating. When silicon-containing compounds are added, molecular sieves, non-stoichiometric aluminum phosphate and silicon-containing compounds are mixed with water to form a slurry.

[0049] In the third step, the above slurry is spray-dried to make microspheres.

[0050] In the fourth step, the microspheres prepared above are calcined at 400-600° C. for 2-10 hours to obtain the microsphere catalyst.

[0051] The catalyst of the present invention can be applied in the reaction of preparing light olefins from residual oil, animal and vegetable oil, hydrogenated tail oil or / and naphtha as raw materials. The low-carbon olefins referred to i

Embodiment 1

[0059] According to the ratio of Al:P=1:0.3, the Al 2 o 3 and H 3 PO 4 Mixing produces non-stoichiometric aluminum phosphate. Make substrate (65wt%) with this aluminum phosphate, mix with LaZSM-5 molecular sieve (35wt%), through spray drying, roast at 400-600 ℃ to make fluidized bed microsphere catalyst (for the equilibrium catalyst mentioned later Phase distinction, the microsphere catalyst is called fresh catalyst).

[0060] The prepared microsphere catalyst was treated with water vapor at 800°C for 10 hours, or at 820°C for 4 hours to prepare an equilibrium catalyst.

[0061]The reaction results on the micro-reactor device:

[0062] Reaction condition: with N 2 As the carrier gas, the flow rate is 22.5ml / min; the catalyst loading volume is 5ml; the reaction raw material is Daqing atmospheric residual oil; the oil intake volume is 0.3g / min.

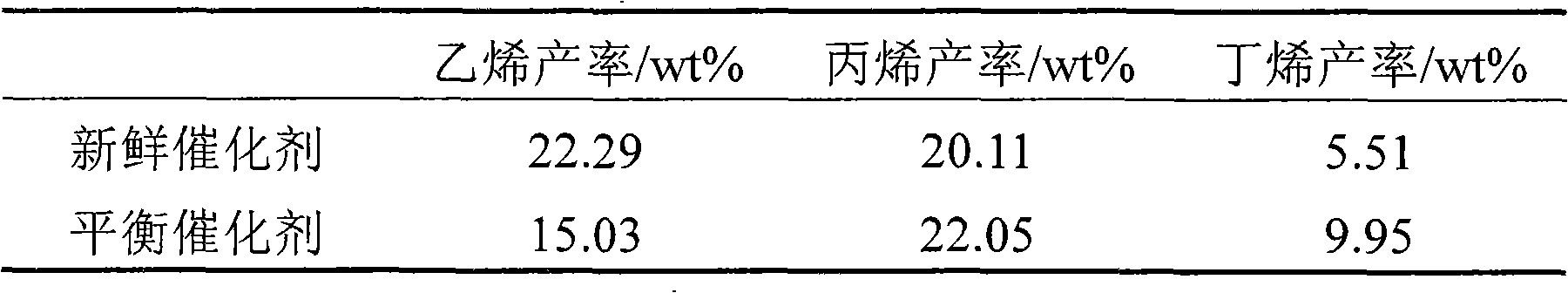

[0063] When reacting at 670°C:

[0064]

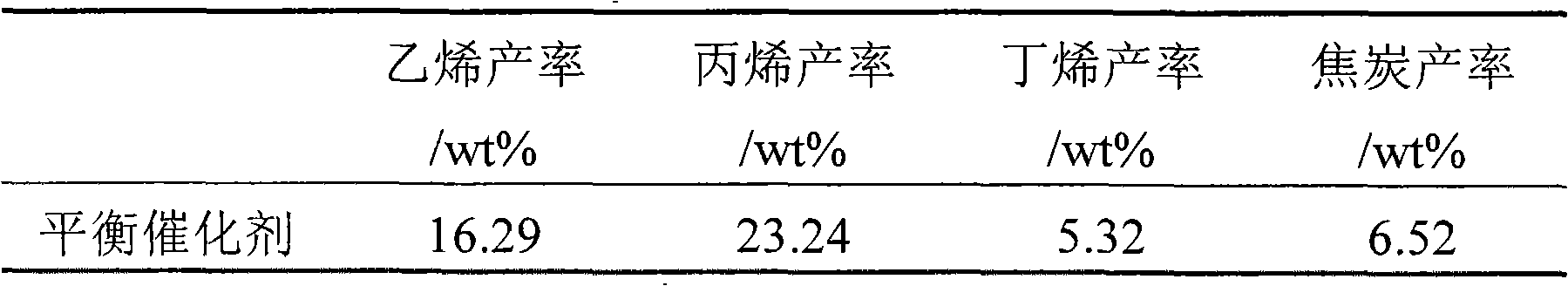

[0065] The result of the reaction in a fixed fluidized bed:

[0066] Reaction c

Embodiment 2

[0070] According to the ratio of Al:P:Si=1:0.92:0.38, the Al 2 o 3 、H 3 PO 4 mixed with silica sol. The mixture is mixed with 35wt% LaZSM-5 molecular sieve by using 65% by weight as a matrix, and then spray-dried and calcined to make a microsphere catalyst.

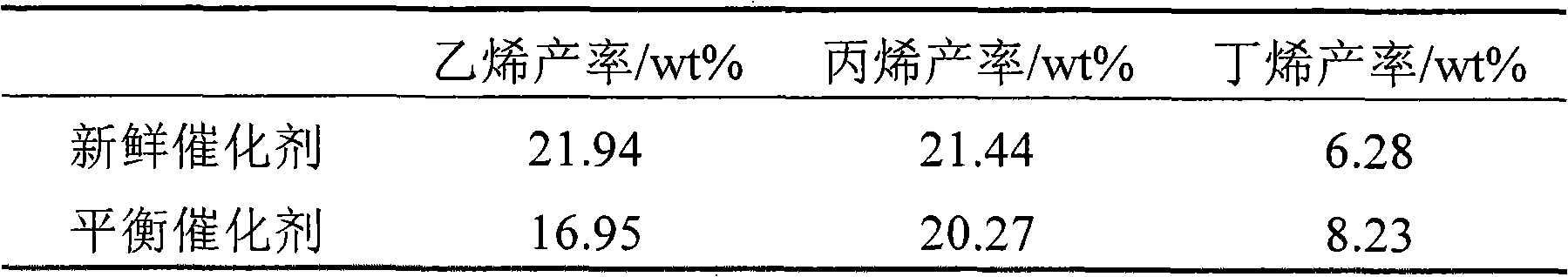

[0071] The reaction result on the micro-reactor device at 670°C (other conditions are the same as Example 1):

[0072]

[0073] Reaction result on fixed fluidized bed (other conditions are the same as example 1) when 660 DEG C:

[0074]

[0075]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap